Finish Thompson LS-55IIE User Manual

Page 20

19

SEMI-ANNUALLY OR AS REQUIRED:

ADJUST LID CLAMPS - Make sure that all of the Still’s lid clamps hold tightly. Adjust any loose clamps, and

replace clamps that appear weak.

CLEAN JETVAC PUMP RESERVOIR - If using a JetVac attachment, drain the pump reservoir and clean and

remove all dirt and debris. Inspect parts for corrosion, and replace any suspect parts.

CLEAN Y-STRAINERS - The Still’s Y-strainer is located inside of its cabinet. The JetVac’s Y-strainer is

located on its left side, in line with the metal braided hose. Remove the screen and clean out the debris. If

mineral deposit or scale is detected, also remove and clean inside the condenser cooling water jacket as well.

CLEAN THE CONDENSER - Remove the condenser and inspect it for scale or residue on both the water and

solvent side. Clean or replace if necessary.

LID LIFT BAR - On LS-55E/55IIE, units grease the lid’s lift bar (located at the rear of the unit) using the two

supplied grease fittings.

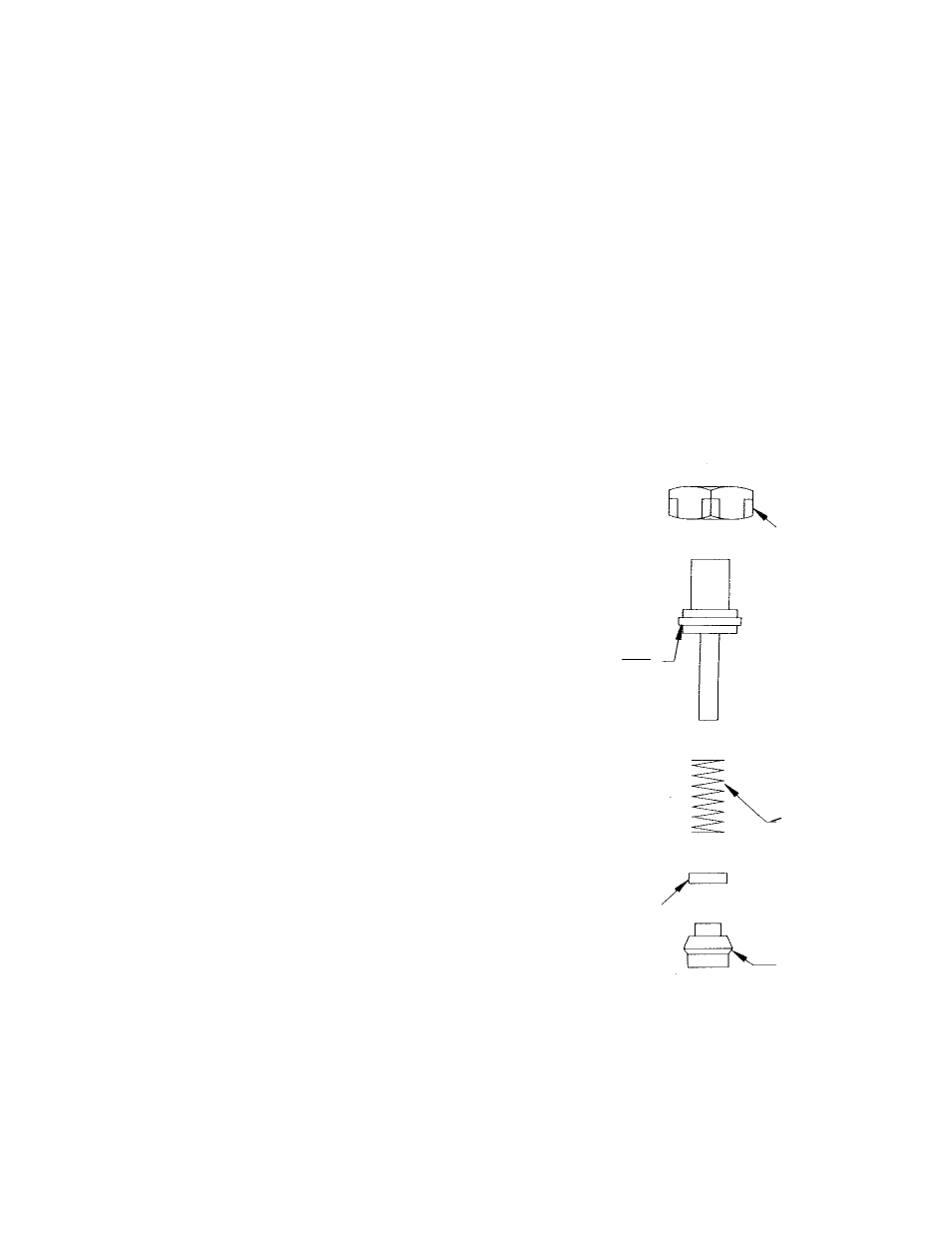

CLEAN THE FLOW SWITCH - The flow switch is

located inside of the Still’s cabinet.

1. Disassemble the flow switch by loosening the large

bonnet nut and pulling the body of the flow switch

free.

2. Clean the shuttle assembly, spring, magnet,

plunger, and body of the flow switch.

3. Place the spring, magnet, and plunger onto the

shuttle assembly, then gently push the body onto

the shuttle assembly. Take care not to damage the

shuttle’s O-ring.

4. Test the operation of the flow switch (see

Maintenance: Weekly).

BONNET NUT

SHUTTLE

ASSEMBLY

SPRING

MAGNET

PLUNGER