Farm Star EM/2 72 User Manual

Page 23

22

19

A S S E M B LY I N S T R U C T I O N S

The mower will attach to most tractors with a Category

I, 3 pt. hitch system and a 540 RPM PTO. Do not

exceed horsepower recommendations.

D A N G E R !

Operating with PTO speed over 540 RPM can cause

excessive vibration and mower failure, which can

result in serious injury or even death.

W A R N I N G !

A loose shaft could slip off and result in personal

injury or damage to the mower. When attaching the

driveline yoke to the tractor PTO shaft, it is important

that the spring activated twist collar turns freely and

that the locking pin is seated on the PTO shaft groove.

W A R N I N G !

Before operating the mower check to make sure the

driveline will not bottom out or become disengaged.

See figure 6.

C A U T I O N !

Always use personal protection devices such as

eye and ear protection during assembly.

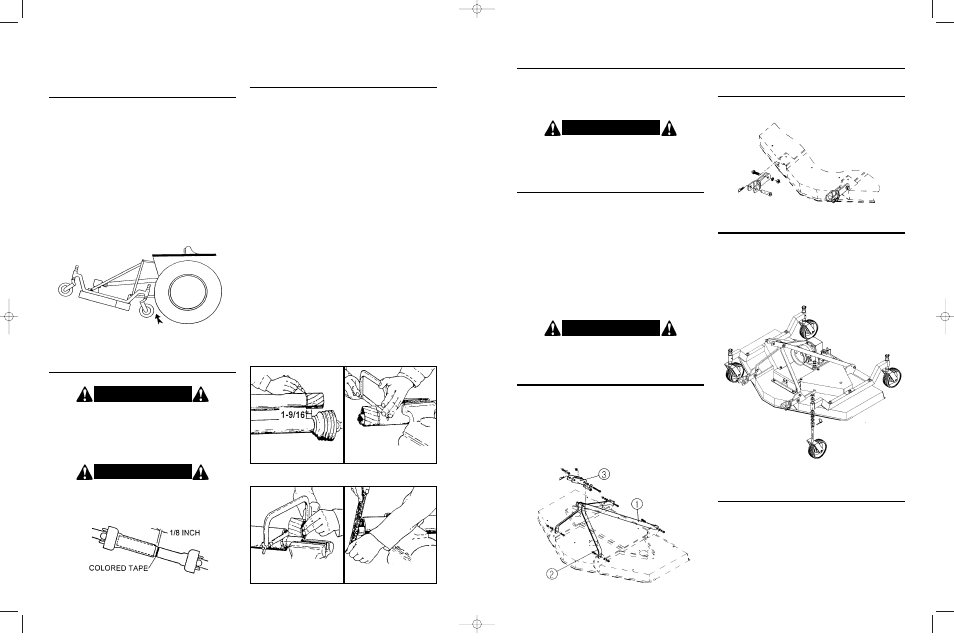

A - F R A M E AT TA C H M E N T

Attach the rear brace bars (1) to the lugs on the rear of

the deck with M12 bolt, washer, lockwasher, and locknut.

Attach the A-Frame bars (2) to the lugs on the front of the

deck with M12 bolt, washer, lockwasher, and locknut.

Attach the other end of the A-Frame bars (2) at the top

and between the rear brace bars and top link (3) with

M12 bolt, (2 each) washer, (3 each) spacer, lockwasher,

and locknut. See figure 1.

D R I V E L I N E T O M O W E R

G E A R B O X AT TA C H M E N T

1. Grab and turn the yoke collar of the driveline end to be

attached to the gearbox. Note: Make sure that you

connect the driveline end with the male shield

tube to the mower.

2. Slide the yoke with the collar turned onto the mower’s

gearbox input shaft. Note: Make sure that the plas-

tic protective cone is mounted on the gearbox.

3. Move yoke back and forth until its locking pin has

engaged on the gearbox input shaft groove.

3 PT. HITCH AT TA C H M E N T

Remove bolt from hitch point location and assemble as

shown in figure 2.

Figure 1

Figure 5

Front Gauge Wheel Clearance

Figure A

Figure B

Figure C

Figure D

Figure 6

Driveline in maximum compressed position

Figure 2

C A S T E R W H E E L AT TA C H M E N T

Figure 3

D E A L E R S E T-UP INSTRUCTIONS

Assembly of this mower is the responsibility of the

dealer. The mower should be delivered to the owner

completely assembled, lubricated and adjusted for

normal cutting conditions.

Set-up mower as received from the factory with these

instructions.

• Remove mower from crate.

• Complete assembly of factory pre-assembled hitch.

• Refer to parts lists and exploded view drawings for

more details.

• To complete assembly, it will be easier if components

are aligned and assembled loosely before tightening

hardware.

A D J U S T I N G D R I V E L I N E L E N G T H

1. Slide the driveline together until it “bottoms out.”

2. Apply colored tape to the inner plastic shield tube

1

/

8

”

from the end of the outer shield tube.

3. Reconnect the driveline to the tractor PTO shaft.

4. Raise the mower to full transport position or until the

driveline just hits the deck at front.

5. If the distance between colored tape and outer shield

tube is 1

9

/

16

” or less, the metal drive tubes

should be shortened per figure A.

6. Shorten the male and female plastic shield tubes

equally. See figure B.

7. The metal drive tubes also have to be shortened in

the same length as the plastic shield tubes. See

figure C.

8. Round off all sharp edges and remove burrs. See

figure D.

9. Apply grease to the metal drive tubes.

10. There should always be a minimum of 1

9

/

16

” clear-

ance between the male and female drive and shield

tubes when the driveline is operated in its shortest

working position.

11. Lower the mower to the lowest position possible and

check the distance of the colored tape to the end of

the outer shield tube.

12. Driveline tube engagement or overlapping must

always exceed 12”.

13. If tubes do not overlap by 12” or more, consult with

your dealer to obtain a longer driveline.

F R O N T G A U G E W H E E L

I N T E R F E R E N C E C H E C K

Do not operate the mower until this interference check

has been performed. If you use the mower with a differ-

ent tractor, you must perform the check for that particular

mounting again.

1. Raise the mower with the tractor hydraulic system to

the maximum height of lift.

2. Pivot both of the mower front gauge wheels forward

and check that there is clearance between the gauge

wheels and the tractor’s rear tires.

3. If there is interference, lower the mower to the ground

and move hitch to the extended position (see assem-

bly chapter).

4. Move the tractor tires inward to obtain clearance or

lower the mower until clearance exists.

5. Set the 3-point quadrant stop so the mower cannot be

raised beyond the set point. See figure 5.

D R I V E L I N E L E N G T H C H E C K

P R O C E D U R E

O P E R ATION I N S T R U C T I O N S

(continued)

Some mowers will be supplied with all four wheels fully

assembled. However, for models that do require

assembly, please follow these instructions. Install two

3

/

4

”

spacers on each fork and wheel assembly shaft. Insert

fork shaft into axle arm weldment. Additionally install two

3

/

4

” and two

3

/

8

” spacers on each axle shaft and retain

using the snapper pins supplied. See figure 3.

22 / 19 - FM001 12/6/00 3:24 PM Page 1