Agri-Fab 45-02882 User Manual

Page 5

5

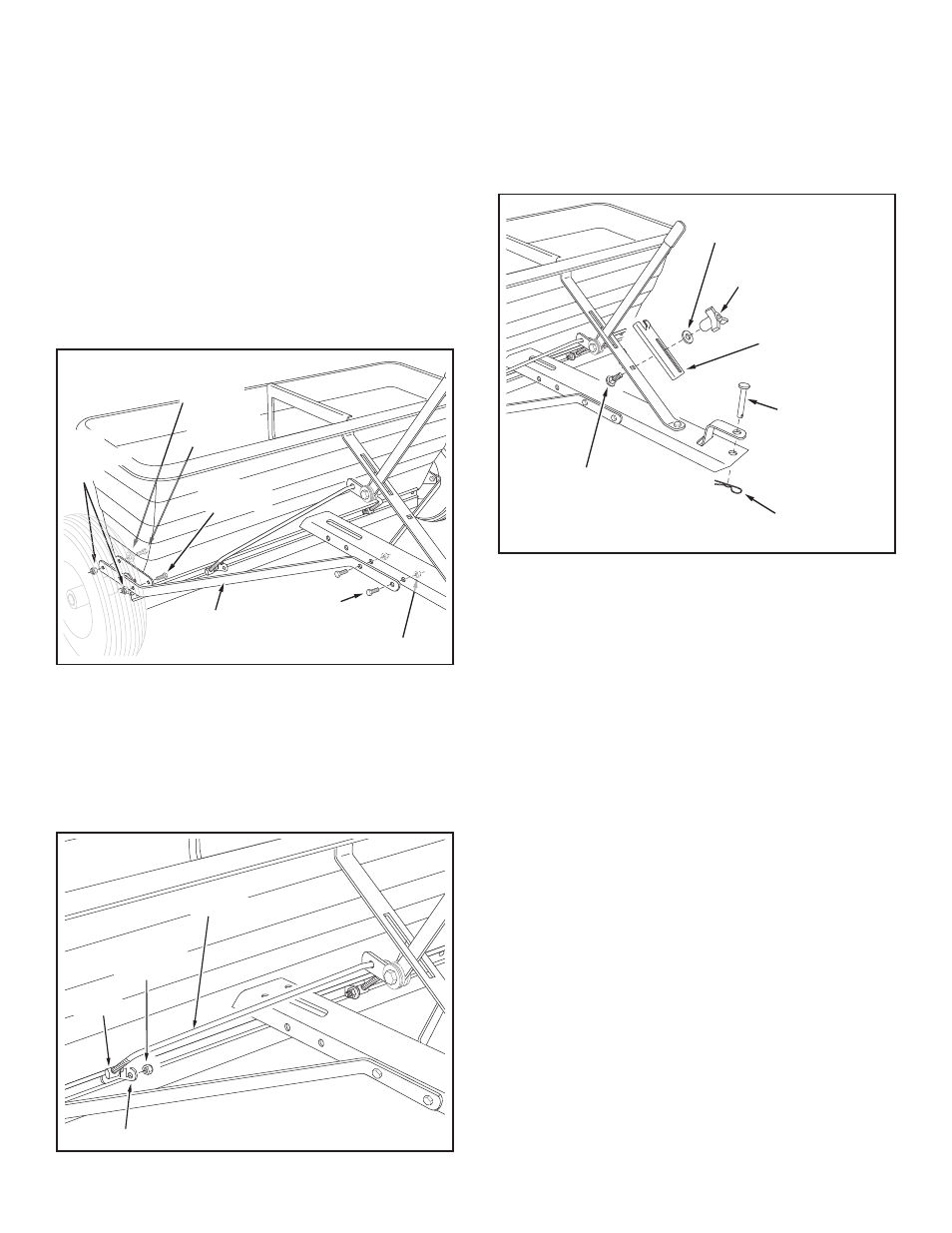

8. Assemble one end of a tongue brace to the side of the

tongue using two 1/4" x 5/8" hex bolts and 1/4" nylock

nuts.

Do not tighten yet. See figure 4.

9. Assemble the other end of the tongue brace to the

triangular plate on the end of the spreader. Use a 1/4"

x 5/8" hex bolt and 1/4" nylock nut in the front hole of

the plate. Use a 1/4" x 3/4" hex bolt, 1/4" flat washer and

1/4" nylock nut in the rear hole, with the bolt and washer

assembled on the inside of the hopper as shown in figure

4.

Do not tighten yet.

10. Repeat steps 8 and 9 to attach the second tongue brace

to the other end of the spreader and then

tighten all

loose bolts.

1/4" NYLOCK

NUT

BRACKET

FERRULE

FLOW CONTROL ROD

FIGuRE 5

11. Make sure that both ferrules are adjusted so that

approximately ten threads (1/2") of the control rod is

exposed. Insert both ferrules into the brackets which are

riveted to the front of the flow plates. Assemble a 1/4"

nylock nut onto each ferrule, making only

finger tight

at this time. See figure 5.

1/4" x 5/8"

HEX BOLT

1/4" FLAT WASHER

(One per side)

1/4" NYLOCK NUT

TONGUE

BRACE

1/4" x 3/4"

HEX BOLT

1/4"

NYLOCK

NUT

1/4" x 5/8"

HEX BOLT

FIGuRE 4

12. Assemble the flow control gauge to the hopper brace

using the 1/4" x 3/4" carriage bolt, a nylon washer and

the plastic knob. See figure 6.

13. Install the hitch pin and the 1/8" hair cotter pin in the

spreader hitch bracket and tongue. See figure 6.

PLASTIC

KNOB

NYLON

WASHER

1/4" x 3/4"

CARRIAGE BOLT

FLOW

CONTROL

GAUGE

1/8" HAIR

COTTER PIN

3/8" HITCH PIN

FIGuRE 6

14. To check for correct opening of hopper flow plates:

a. Set the flow control gauge at the highest setting.

b. Move the flow control arm away from the hopper until

it rests against the gauge. The slots in the bottom

of the hopper should now be completely open. The

edge of the flow plates should be just clear of the

ends all the slots.

c. If the flow plates are not straight with the slots, screw

one ferrule up or down on one side of the control

rod.

d. If the flow plates open to far or not far enough, screw

both ferrules equally up or down on the control

rod.

d. Move the flow control arm toward the hopper to the

off position. Verify that the slots in the bottom of the

hopper are completely covered by the flow plates.

e.

Tighten the lock nuts and then loosen 1/4 turn.

15. To check for proper tension on the hopper flow plates:

a. Set the flow control gauge at a mid range setting.

b. Move the flow control arm against the gauge.

c. Press firmly against the front of the flow plates at the

bottom of the hopper. The flow control arm should

not move.

d. If the arm moves, tighten the hex lock nuts on the

flow control arm until movement is prevented.