Darex v390 maintenance – Darex V-390 User Manual

Page 16

16

DAREX V390 MAINTENANCE

Cleaning the DAREX V390

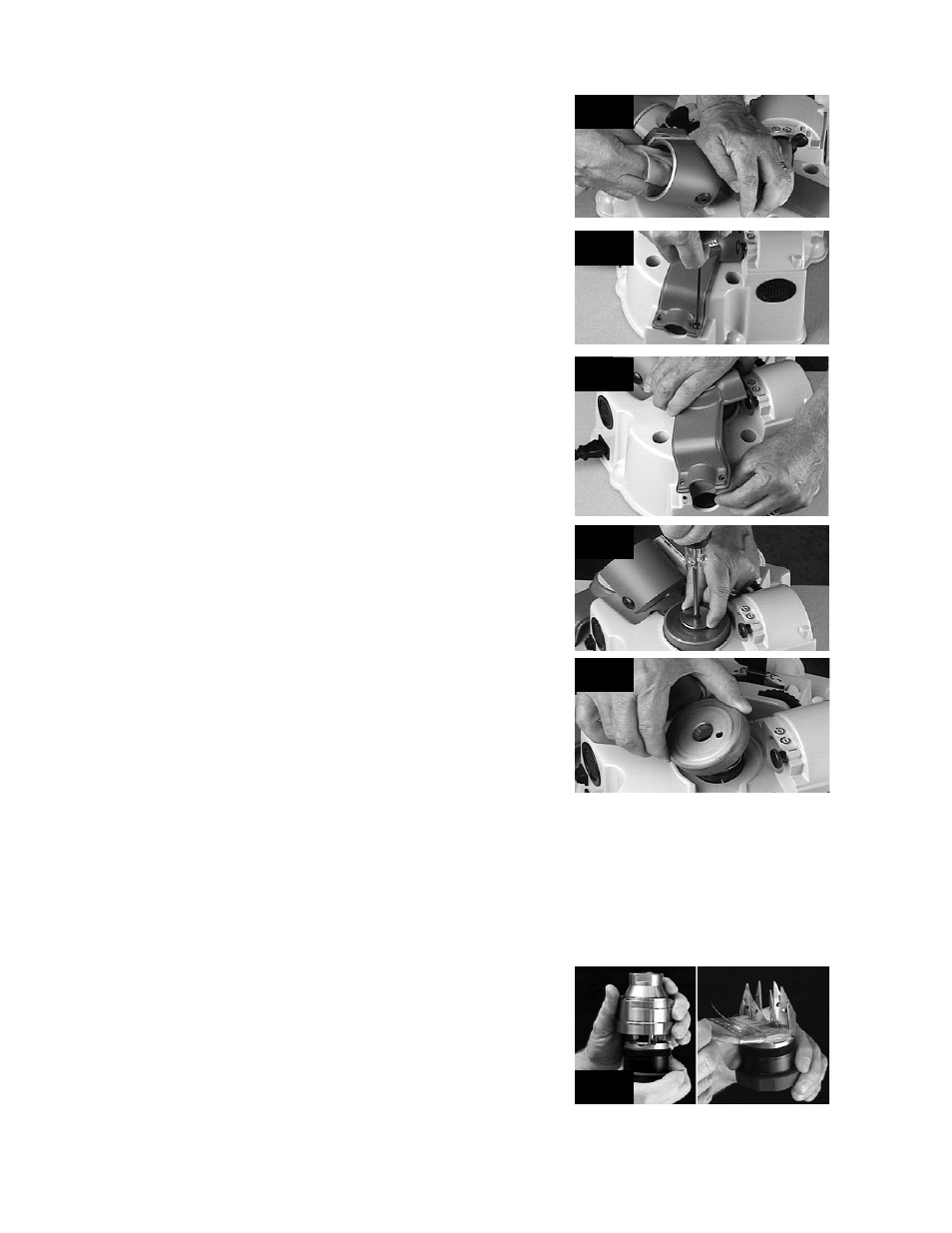

Unplug the Drill Bit Sharpener. Using a dry paintbrush or a cloth,

clean the inside and outside of the Alignment, Sharpening and

Splitting ports to remove any grindings that may have accumu-

lated. (See Picture #25) The attachment of a vacuum with a stan-

dard vacuum hose works well to keep the grit area clean. (See

“Vacuum Tube” below)

Removing the wheel cover

Unplug the Drill Bit Sharpener. Using a 3mm hex wrench, remove

the three hex head screws holding the wheel cover on. (See Pic-

ture #26) Lift the wheel cover off and with a dry brush remove

any grinding dust. (See Picture #27)

Determining if a wheel change is required

1. Sharpened drill bits will burn or turn blue no matter how fast or

slow you rotate the chuck.

2. Upon inspecting the wheel, it appears smooth as if there is no

abrasive. (See “Cleaning the electroplated CBN or diamond

wheel” )

3. When sharpening a drill bit, if it takes an extreme number of

rotations to sharpen the tool, then the wheel will need to be re-

placed. Contact the company or distributor where the sharpener

was purchased for replacement wheels.

Removing the wheel

MAKE SURE THE UNIT IS UNPLUGGED! Once wheel cover is re-

moved, insert a Phillips head screwdriver into the wheel retainer

bolt on the top of the wheel and turn it counterclockwise to loosen.

(See Picture #28) Using a hex wrench remove the bolt and wheel

retainer. Lift the wheel off of the motor hub. (See Picture #29)

Remove dust particles from the wheel hub and grinding wheel area

with a small dry brush. Dispose of drill grinding dust in a safe and

environmentally approved manner. Prior to re-installing the wheel

make sure to clean all grindings off of hub and wheel.

Replacing the wheel

To re-install wheel, reverse steps taken to remove wheel.

Cleaning the chuck

Using pressurized air, blow grindings out of the chuck from the

knob end. For further cleaning, disassemble the chuck by merely

unscrewing the closing knob on the chuck and removing the chuck

body. Clean the inside of the chuck with a dry paintbrush. Do not

remove the springs and jaws from the holder! Once the inside of

the chuck has been cleaned, apply a drop or so of light lube on the

threads. Slide the chuck body onto the jaws, rotate the closing

knob clockwise to reassemble the chuck. (See Picture #30)

Pic 25

Pic 26

Pic 27

Pic 28

Pic 29

Pic 30