Principle of pump operation, Universal all aodd, Submerged illustration – Blagdon Pump X25 Metallic Flap Valve User Manual

Page 7: Inst al & op

x25fvdl2sm-rev0213

Model X25 Metallic •

4

www

.

blagdonpump

.

com

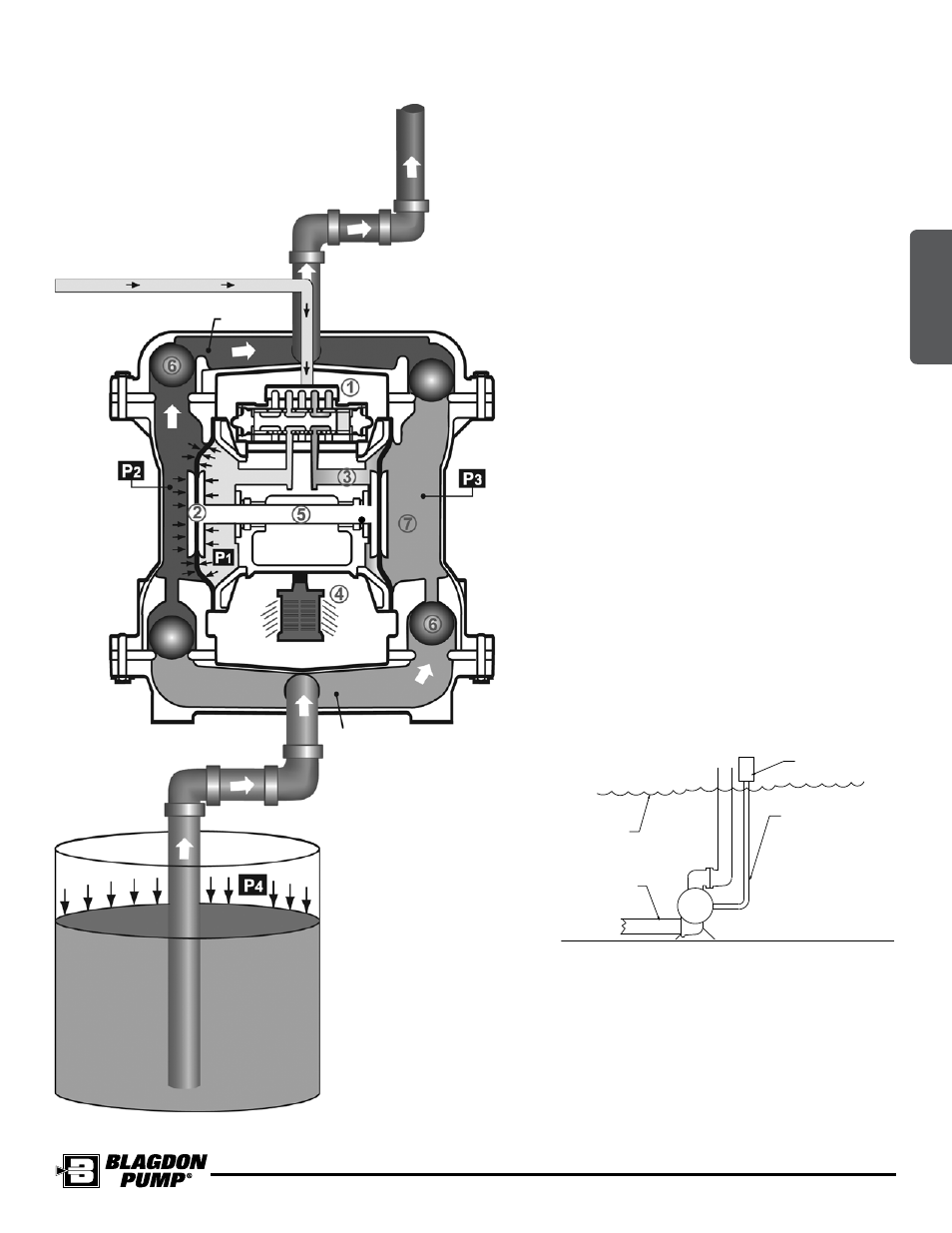

Air-Operated Double Diaphragm (AODD) pumps are powered

by compressed air, nitrogen or natural gas.

The main directional (air) control valve

①

distributes

compressed air to an air chamber, exerting uniform pressure

over the inner surface of the diaphragm

②

. At the same time,

the exhausting air

③

from behind the opposite diaphragm

is directed through the air valve assembly(s) to an exhaust

port

④

.

As inner chamber pressure

(P1)

exceeds liquid chamber

pressure

(P2)

, the rod

⑤

connected diaphragms shift

together creating discharge on one side and suction on the

opposite side. The discharged and primed liquid’s directions

are controlled by the check valves (ball or flap)

⑥

orientation.

The pump primes as a result of the suction stroke. The

suction stroke lowers the chamber pressure

(P3)

increasing

the chamber volume. This results in a pressure differential

necessary for atmospheric pressure

(P4)

to push the fluid

through the suction piping and across the suction side check

valve and into the outer fluid chamber

⑦

.

Suction (side) stroking also initiates the reciprocating

(shifting, stroking or cycling) action of the pump. The suction

diaphragm’s movement is mechanically pulled through its

stroke. The diaphragm’s inner plate makes contact with an

actuator plunger aligned to shift the pilot signaling valve.

Once actuated, the pilot valve sends a pressure signal to the

opposite end of the main directional air valve, redirecting the

compressed air to the opposite inner chamber.

Principle of Pump Operation

Air Line

Discharged

Fluid

Discharge

Stroke

Suction

Stroke

Primed

Fluid

2.57

65

6.89

175

"D"

16.73

425

15.59

396

DISCHARGE PORT

1" BSP Tapered

1" NPT

AIR INLET

1/2" NPT

14.03

356

2.38

60

"C"

.72

18

8.57

218

"A"

"B"

2.38

60

16.41

417

SUCTION PORT

1" BSP Tapered

1" NPT

(OPTIONAL 90

PORT ROTATION)

AIR EXHAUST

3/4" NPT

8.56

217

9.00

229

4X

.28 [7] MOUNTING HOLE

NOTE:

UNIT FURNISHED WITH SUB-BASE PLATE

AND RUBBER FEET AS STANDARD. FOR

STATIONARY BOLT DOWN USE, RUBBER

FEET CAN BE REMOVED.

HEAVY DUTY FLAP VALVE PUMP

DIMENSIONAL TOLERANCE 1/8 [3]

[XX] = MILLIMETERS

PUMP

COFIGURATION

DIM "A"

DIM "B"

DIM "C"

DIM "D"

ALUMINUM

CENTER SECTION

3.95 [100]

5.86 [149] 11.12 [282] 14.55 [370]

CAST IRON

CENTER SECTION

4.10 [104]

5.54 [141] 10.80 [274] 15.75 [400]

PULSE OUTPUT

CONFIGURATION

SAFE AIR

EXHAUST

DISPOSAL

AREA

PUMP INSTALLATION AREA

1" DIAMETER AIR

EXHAUST PIPING

1" DIAMETER AIR

EXHAUST PIPING

1" DIAMETER AIR

EXHAUST PIPING

MUFFLER

LIQUID

LEVEL

SUCTION

LINE

LIQUID

LEVEL

SUCTION

LINE

MUFFLER

MUFFLER

SUBMERGED ILLUSTRATION

Pump can be submerged if the pump materials of construction

are compatible with the liquid being pumped. The air exhaust

must be piped above the liquid level. When the pumped product

source is at a higher level than the pump (flooded suction

condition), pipe the exhaust higher than the product source to

prevent siphoning spills.

UNIVERSAL ALL AODD

2: INST

AL

& OP