Trouble shooting guide, Trouble shooting guide & technical data, Technical data – Blagdon Pump X15 PTFE Non-Metallic User Manual

Page 5

HG-CF-1119 Rev. F – 10.12.09

Page 5

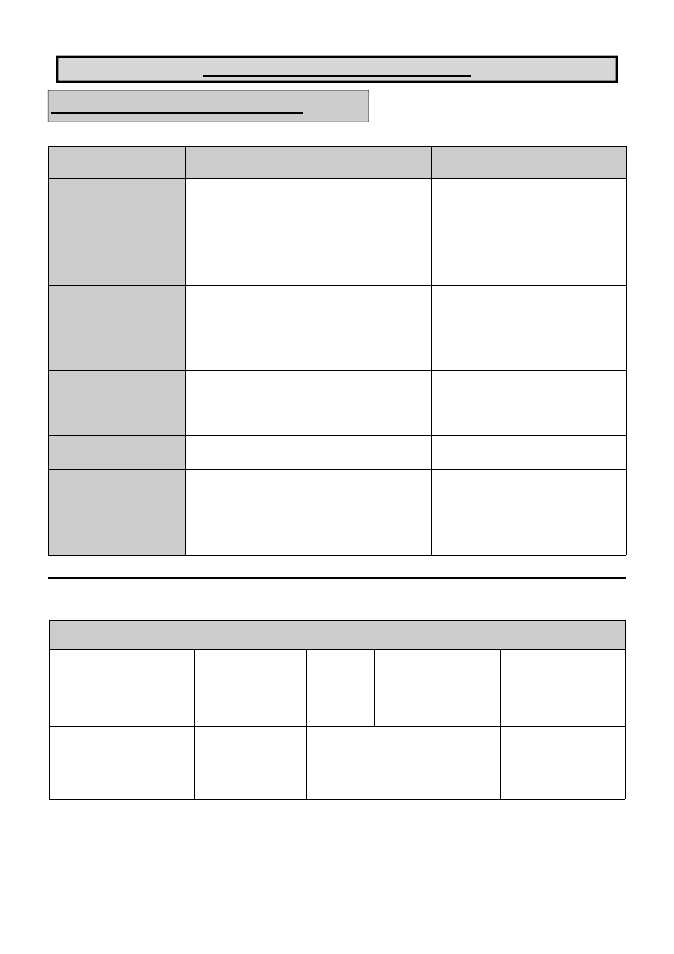

TROUBLE SHOOTING GUIDE

NOTE :- Check all solutions before dismantling the pump.

PROBLEM

CAUSE

SOLUTION

Pump will not start

Air valve assembly malfunction/Seizure

Obstructed fluid line.

Obstructed diaphragm chamber.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Air connected to exhaust.

Check carrier for freedom of movement. -

Clean, oil & replace.

Clean line or increase line size.

Remove obstruction.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Re-connect to air inlet.

Erratic flow

Diaphragm failure on one side.

Valve ball not seating.

Suction leakage.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Replace diaphragm.

Check and remove obstruction.

Check and correct.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Pump strokes but will not

discharge

Excessive suction lift.

Suction line leakage.

Valve ball not seating correctly or damaged.

Suction line or strainer clogged.

Diaphragm failure.

Shorten suction line.

Check and correct.

Check and remove obstruction / replace.

Clear.

Replace diaphragm.

Fluid discharged from air

exhaust

Diaphragm Failure.

Loose frontplate.

Replace diaphragm.

Re-Torque to manual specifications.

Intermittent stroke rate

Over lubrication

Diaphragm shaft seal failure.

Air valve system malfunction.

Valve ball not seating / partially obstructed.

Shut-down pump. Remove air connection

into pump & introduce a small quantity of de-

greasing agent into air valve and replace

line. Run pump until clear.

Replace seals.

Check all seals in valve chest assembly.

Clear obstruction.

Trouble Shooting Guide & Technical Data

For overall dimensions see page 7

FLUID CONNECTIONS

CAPACITY

MAX SOLIDS

MAX DISCHARGE HEAD

DISPLACEMENT

PER STROKE

1/2” BSP

1/2” ANSI 150 Flange

0 - 48 Litres/Minute

(0 - 10.5 Gallons/Minute)

2 MM

(5/64”)

70 Meters

(230 ft)

0.075 Litres

(0.02 UK Gallons)

MAX. WORKING PRESSURE

AIR INLET

TEMPERATURE LIMITS

PUMP WEIGHTS :-

7.0 Bar (100 psi)

1/4” BSP (F)

100°C PTFE & Conductive PTFE

TS / 44 :- 12.5 Kg

TECHNICAL DATA