FEC AFC1100 User Manual

Page 2

)(& ,QF

6.1

Fastening Control Methods

The AFC1100 System is user programmable to select from two different fastening methods,

referred to as Torque Control, and Angle Control methods. Each method can be configured

to perform the fastening in 1 to 2 incremental steps.

6.1.1 Torque Control Method

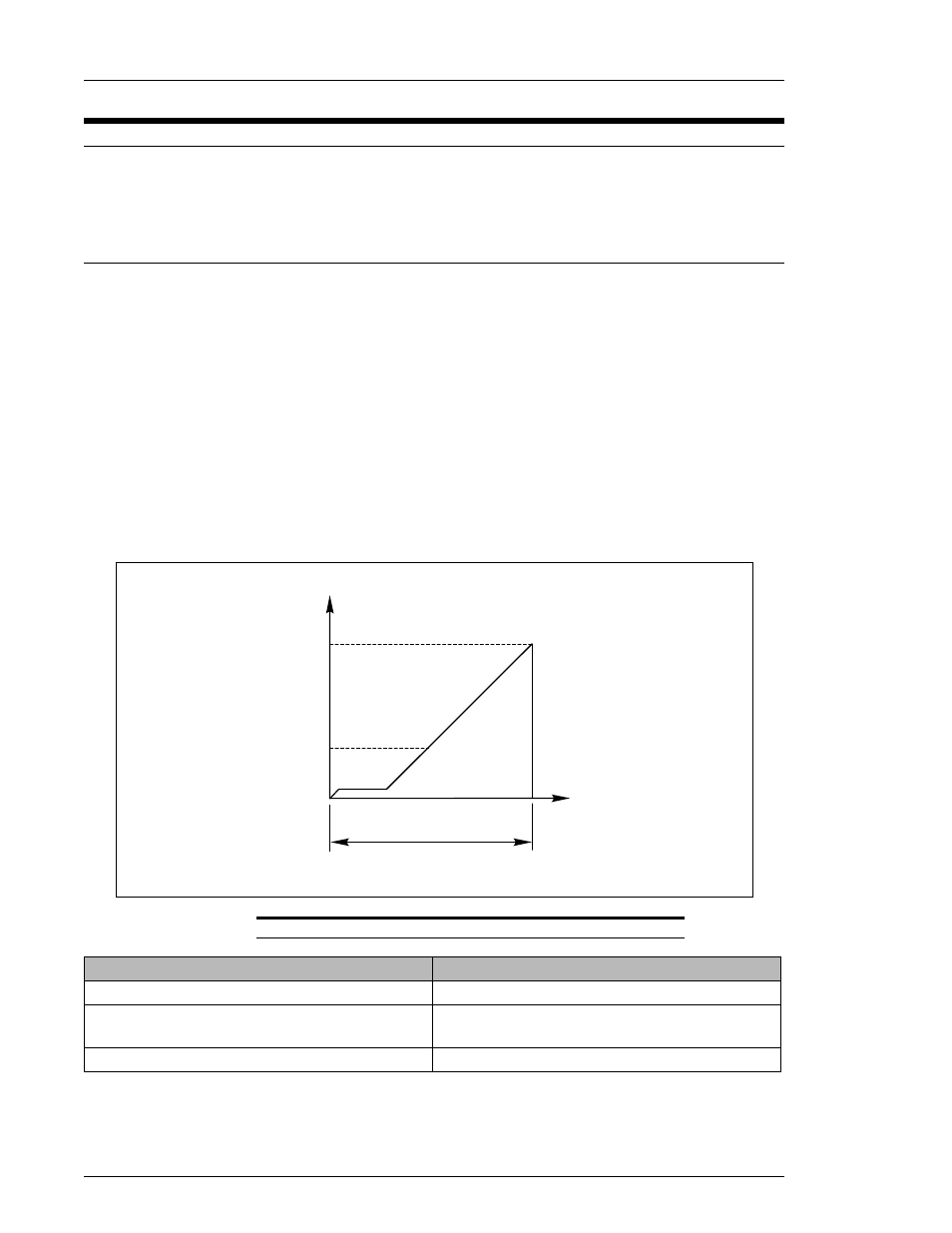

In Torque Control method, fastening is performed based upon attaining a desired torque

value. Fastening can be performed in 1 to 2 incremental step which will successively secure

the fastener to the specified torque values.

{ One-Step Fastening

P The System fastening parameters must be configured in accordance with the

Engineered fastening specification.

P One-step fastening will be used primarily for joints which have no requirement to

synchronize with another spindle during the final stage of the rundown.

Examples: Pipe plugs, single spindle applications.

P The System will fasten to the STD torque value during the specified 1ST STEP

time. Once SPEED CHANGE TORQUE is reached, the System will switch to the

specified TORQUE SPEED (Section 6.3).

STD.

TORQUE

1ST STEP

ANGLE

SPEED CHANGE

FIG. 6-1-1a Torque Control Functions for One-Step Fastening

Maximum allowable fastening cycle time

1ST STEP (TIME)

30 ~ 50% of STD for Hard joints

50 ~ 90% of STD for Soft joints

SPEED CHANGE (TORQUE)

Engineered fastening specification

STD

RECOMMENDATION

FUNCTION

Chapter 6: Fastening Instructions (Rev. 8/98)

Page 6-2