FEC AFC1100 User Manual

Page 10

)(& ,QF

6.3

Speed Functions

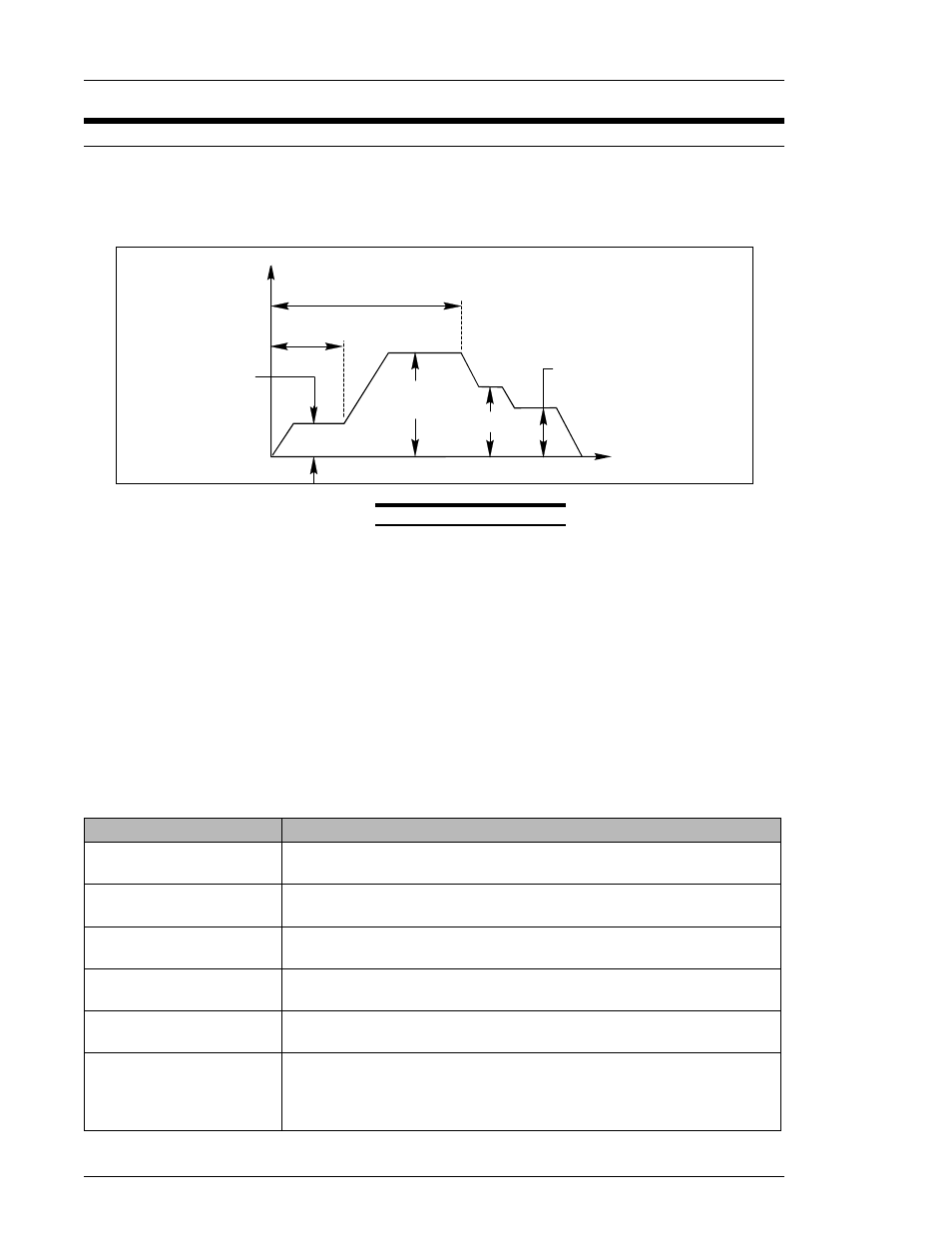

The AFC1100 System is user-programmable for operations involving multiple speed settings.

The use of multiple speeds during the fastening process aids in socket engagement,

achieving cycle time, and controlling the applied torque during all stages.

SPEED

TIME

INITIAL TIME

FREE RUN

SPEED

SLOW DOWN

SPEED [80]rpm

TORQUE SPEED

[40]rpm

[200]rpm

FREE RUN TURN

[2.0] sec

INITIAL SPEED

[40]rpm

[10.0] rev

FIG. 6-3a Speed Functions

{ The System will run at INITIAL SPEED for the time specified by the setting of INITIAL

TIME.

{ Once INITIAL TIME has elapsed, the System will switch to FREERUN SPEED (High Speed

Rundown) for the number of revolutions specified by FREERUN REVOLUTIONS. If the

System has been set up properly, the nutrunner will shift to SLOWDOWN SPEED before

seating the fastener. The nutrunner will run at SLOWDOWN SPEED until either 1st

TORQUE/ANGLE is reached or until 1st STEP TIME expires. If 1st STEP TIME expires

before reaching 1st TORQUE/ANGLE, the System will output a Time Over reject.

NOTE: The System will shift to TORQUE SPEED if either SPEED CHANGE TORQUE or

1st TORQUE/ANGLE is sensed, no matter which step is being performed.

{

FINal torque speed to which the nutrunner will shift once 1st

TORQUE/ANGLE or SPEED CHANGE Torque is reached. SET based

upon the joint type to allow for a controlled final fastening. LESS THAN

50 RPMs.

TORQUE SPEED

FIRSt torque fastening speed. SET based upon the joint type to allow

for a controlled seating. LESS THAN 150 RPMs.

SLOWDOWN SPEED

Set based upon cycle time requirements. THIS speed is used to run

down the bolt quickly.

FREERUN SPEED

FOR joints that do not react properly to high speed seating, the freerun

time should be calculated to eliminate the "crash" effect.

FREERUN

REVOLUTIONS

SET to the rpm which will allow for easy socket to fastener

engagement.

INITIAL SPEED

SET to a duration which will provide sufficient time for the socket to

fastener engagement. set in seconds.

INITIAL TIME

RECOMMENDATION

FUNCTION

Chapter 6: Fastening Instructions (Rev. 1/98)

Page 6-10