FEC AFC1200 User Manual

Page 7

)(& ,QF

Maximum allowable Final Step time

FINAL STEP (TIME)

Maximum allowable fastening cycle time

1ST STEP (TIME)

Engineered fastening specification for rotation

angle

FINAL ANGLE

30 ~ 50% of resultant torque for Hard joints

50 ~ 90% of resultant torque for Soft joints

SPEED CHANGE (TORQUE)

Engineered fastening specification at which Angle

Control begins

THRESHOLD 2 (TORQUE)

30 ~ 50% of FINAL ANGLE or resultant torque for

Hard joints

50 ~ 90% of FINAL ANGLE or resultant torque for

Soft joints

1ST TORQUE/ANGLE

RECOMMENDATION

FUNCTION

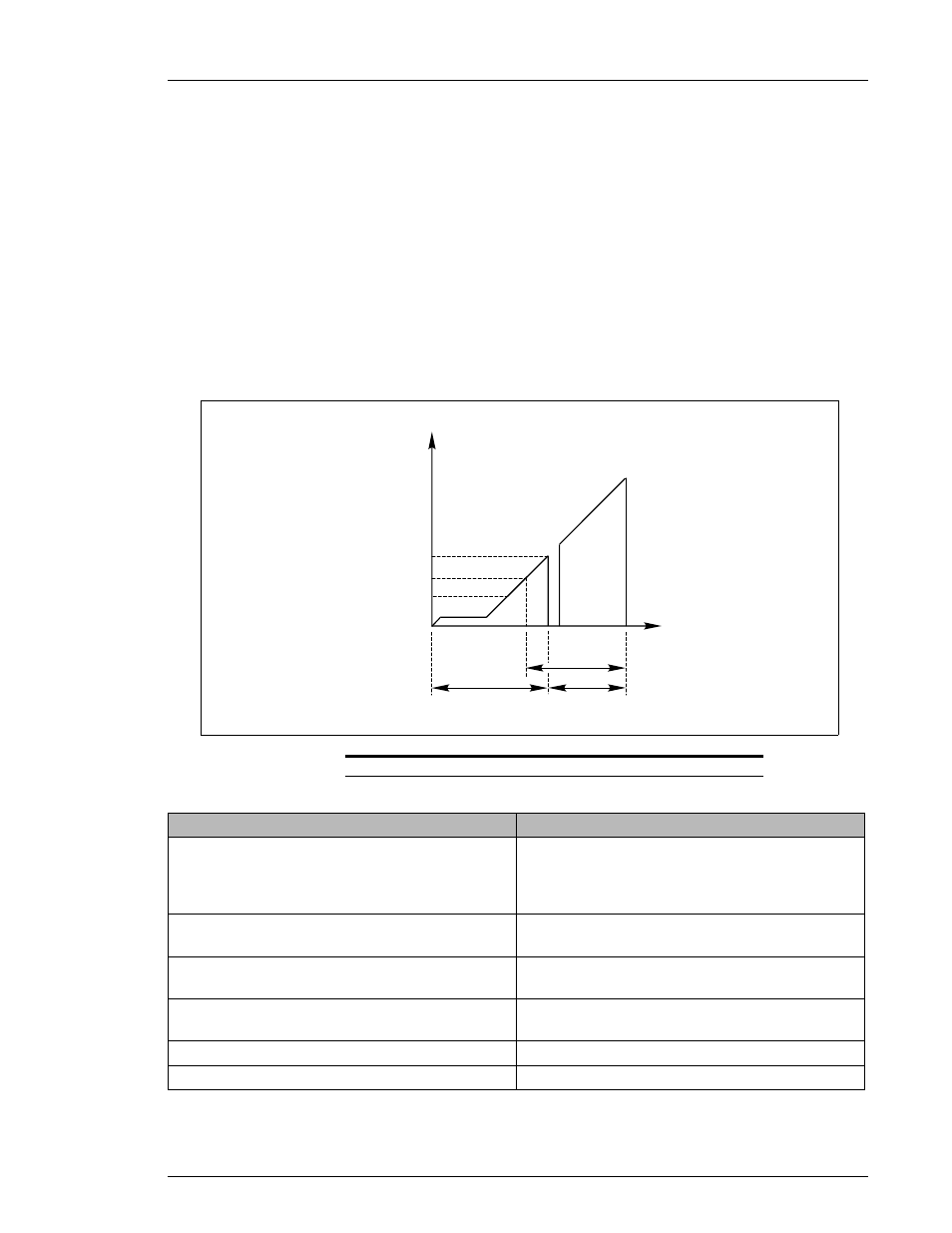

P After presetting the fastening sequence (Section 7.5 SET SEQUENCE ) to perform

a two-step fastening, the System fastening parameters (Section 7.1 PARAMETER

SET) must be configured according to the Engineered fastening specification.

P Two-step fastening will be used primarily for joints that have a requirement to

synchronize with another spindle during the final stage of the rundown (connecting

rod, main bearing cap, and any other multiple-spindle unit, for example).

P The System will fasten to the 1ST TORQUE/ANGLE during the specified 1ST

STEP time. Once either SPEED CHANGE TORQUE or 1ST TORQUE/ANGLE is

reached, the System will switch to the specified TORQUE SPEED (Section 6.3).

When all fasteners have reached 1ST TORQUE/ANGLE, the spindles will

synchronize and then rotate simultaneously the specified number of degrees from

THRESHOLD 2 TORQUE to FINAL ANGLE within the specified FINAL STEP time.

TORQUE

FINAL

ANGLE

1ST STEP

FINAL

STEP

ANGLE

THRESHOLD 2 TORQUE

1st TORQUE / ANGLE

SPEED CHANGE

FIG. 6-1-2b Angle Control Functions for Two-Step Fastening

Chapter 6: Fastening Instructions

Page 6-7