2 area yield method – FEC AFC1200 User Manual

Page 13

)(& ,QF

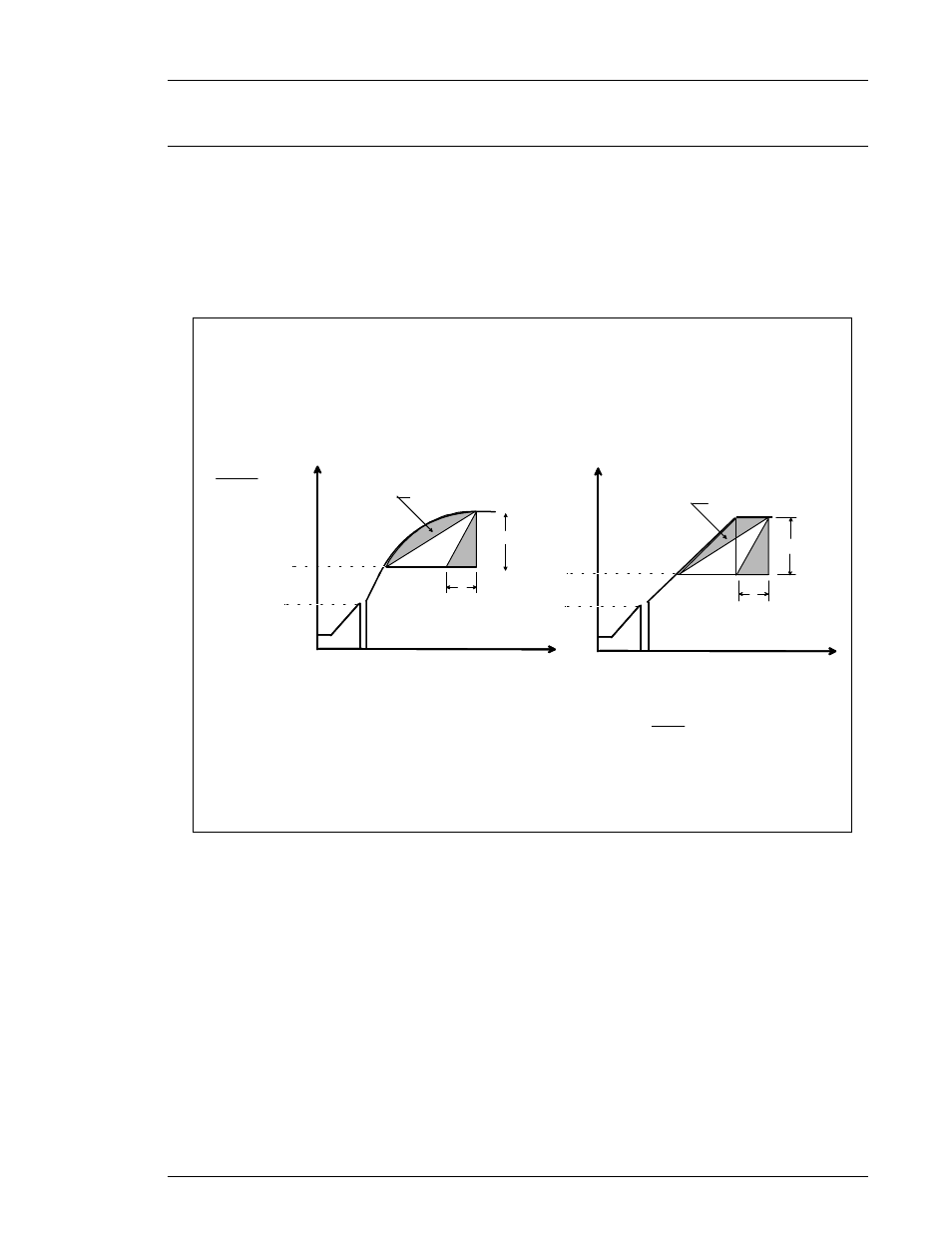

6.1.3.2 Area Yield Method

The Area Yield Method will be the primary controlling method on fasteners that do not have a

clearly definable yield point. These fasteners will exhibit a gradual change in torque rate as

the fastener is elongated. This calculation of the elongation area (EA) allows the System to

simulate the fastener as if it had displayed a clearly defined yield point. When the actual

elongation area (EA) is equal to or greater than the calculated/simulated elongation area the

proper bolt stretch (LENGTH) has been obtained.

SCREW PITCH

LENGTH

ANGLE

YIELD RATE

CONSTANT

A

B

AREA "EA"

A

B

AREA "EA"

ELGA

=

ELGA

ANGLE

ANGLE

ACTUAL

EQUIVALENT (SIMULATED)

THE FASTENING PROCESS

WILL STOP WHEN:

EA

2

A x B

ELGA

>

TORQUE

TORQUE

= ELONGATION A NGLE

1ST

TORQUE / ANGLE

PRESET ITEMS

CONSTANT

AREA YIELD

METHOD START POINT

FIG. 6-1-3-2 Yield Control Function for Area Yield Method

w Area Yield Method Fastening

P After presetting the fastening sequence (Section 7.5 SET SEQUENCE) to perform

the desired number of steps, the System fastening parameters (Section 7.1

PARAMETER SET) must be configured according to the Engineered fastening

specification.

P Multiple-step fastening will be performed according to the Torque and Angle

Control Method procedures. Area Yield Control will begin when the fasteners attain

either CROSSOVER AREA torque, or (Threshold 2 torque + Crossover Area

angle). No incremental steps may be performed which will occur after the

commencement of the Area Yield Control (CROSSOVER AREA). It is therefore

highly recommended that Yield Control operations be restricted to no more than

two steps.

Chapter 6: Fastening Instructions

Page 6-13