Trace oxygen analyzer model 316ra/rb/rad/rbd – Teledyne 316RA / RB / RAD / RBD - Oxygen analyzers User Manual

Page 9

TELEDYNE ANALYTICAL INSTRUMENTS

5

Trace Oxygen Analyzer Model 316RA/RB/RAD/RBD

Location

The Series 316 Trace Oxygen Analyzer should be installed at viewing

level in a sheltered area. The analyzer case is not to be considered water

tight by the customer.

NOTE: Auxiliary heating MUST be provided in areas where the ambient

temperature drops below 32°F.

For the location and identification of the gas line, electrical connec-

tions, and physical dimensions of the analyzer, see the Outline Diagram

(RA: B-40393; RB: C-38551; RAD: B-40400).

After making the panel cutout, TAI suggests line drilling the mounting

holes using the analyzer case itself as a template.

Gas Line Connections

The sample inlet and outlet connections are:

RA:

¹/

8

" female N.P.T.

RB:

¹/

8

" tube fitting

RAD: ¹/

8

" female N.P.T.

TAI suggests using a Teflon sealing tape as a sealant rather than pipe

dope. Make sure that mating fittings are not cross-threaded before applying

force with wrench.

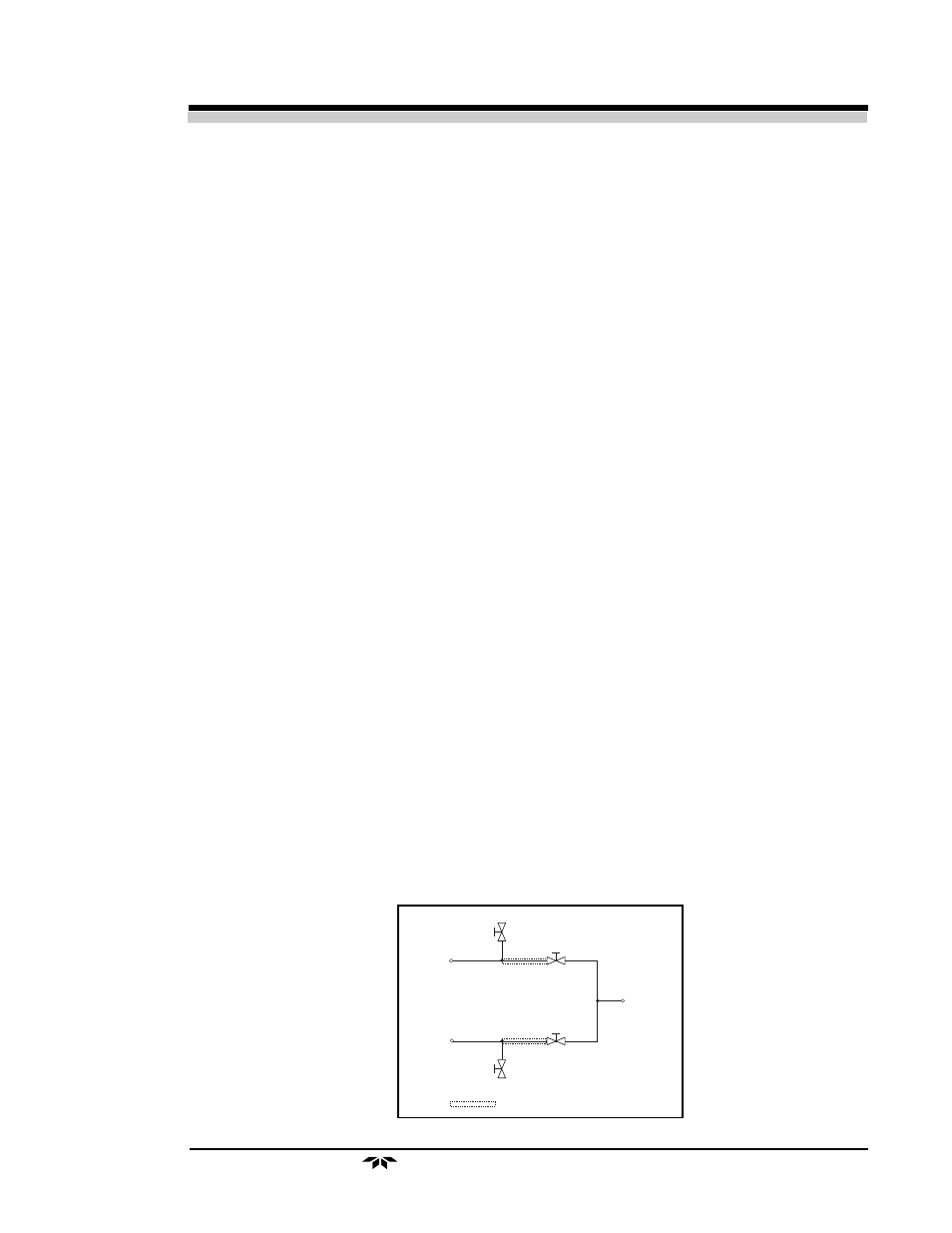

Input Selector Manifold (Optional)

A simple manifold is necessary to introduce either sample or calibra-

tion (span) gas into the analyzer. TAI recommends the manifold design

shown. Span purge and sample purge lines are necessary to flush oxygen

accumulated in the lines due to minute leaks. Just prior to switching to

either gas source, the respective purge valve should be opened for a short

period of time (10-30 seconds). Good quality, 2-way needle valves should

be used. Three-way valves may be used but are not recommended.

TO ANALYZER

INLET

SAM PLE IN

SPAN G AS

IN

SPAN

PURGE

= M INIM IZE LENG TH

SAM PLE

PURGE