Pump maintenance chart, Maintenance instructions, Force locking nut deflection retaining bolt – SPP Pumps Auto Prime Medium Head Open Set - ACE Range User Manual

Page 7

Operators Instructions for

ACE80/100 Diesel Driven Centrifugal Pumps

Manual No/Rev

W72-019E / 4

6. PUMP MAINTENANCE CHART

For engine maintenance periods refer to the engine operators handbook supplied with this manual.

PERIOD

TASK

Daily

Visually check for leaks.

Check for vibration.

Check the mechanical seal oil level and top up as required.

Weekly or

100 hrs

Check all fastener security.

Check the condition of the lifter bracket/frame and check the security of attachment to

the unit.

Check tension of vacuum pump drive belt.

6 monthly

or 1500 hrs

Check reflux ball is sealing on its seat.

Check and if necessary renew vacuum pump drive belt.

Dismantle and clean valve gear, tank, connecting pipes and priming tank.

Change mechanical seal oil.

Annually or

6000 hrs

Check vacuum pump blade condition

The above schedule is given for guidance but site operating conditions may override the suggested

maintenance intervals

.

7. MAINTENANCE INSTRUCTIONS

7.1 Mechanical Seal Oil Reservoir

Maintain the oil level between the maximum

and minimum levels marked on the dipstick.

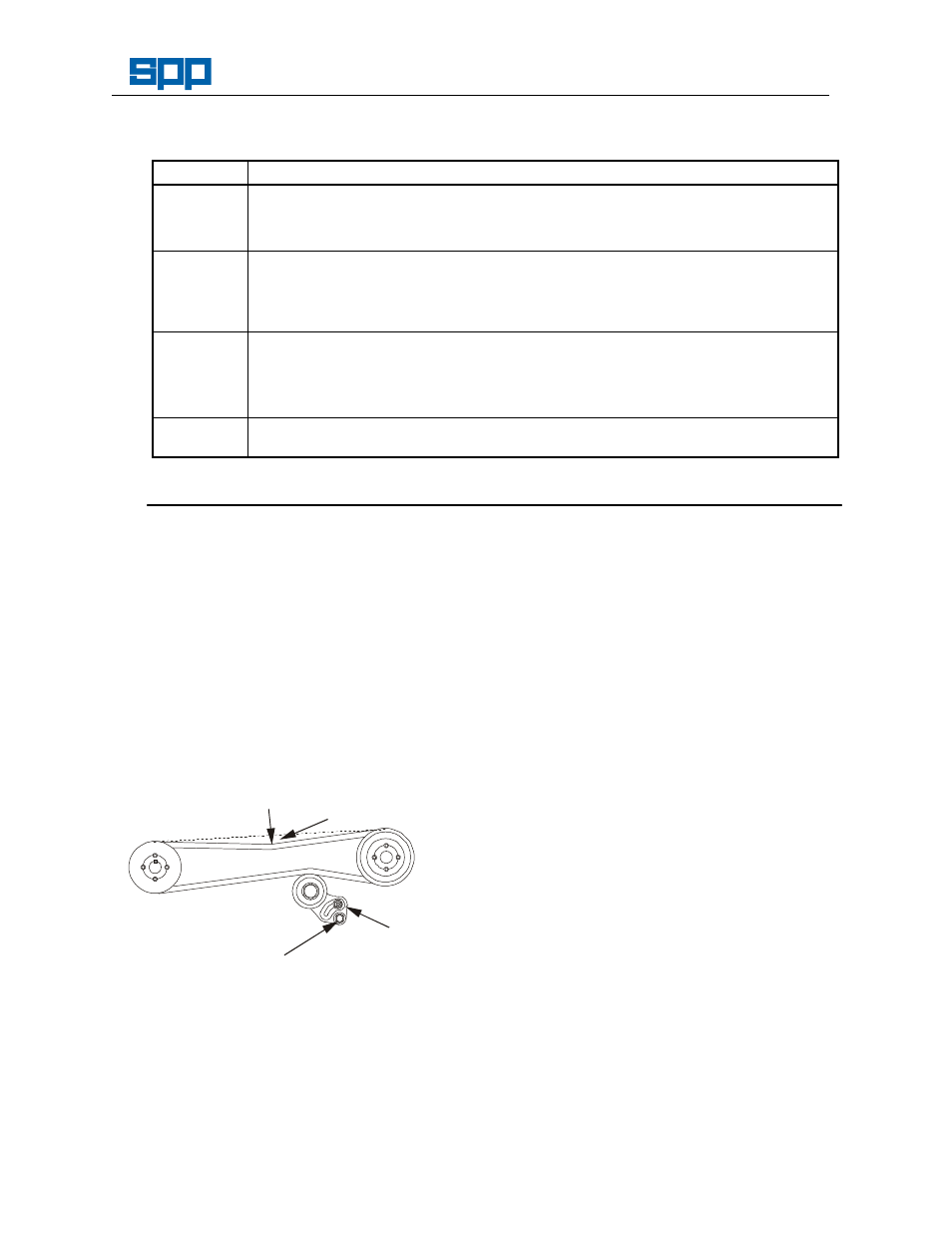

7.2 Drive Belt Adjustment

7.2.1

Remove guard.

7.2.2

Slacken the locking nut and the retaining

bolt, rotate the tensioner to adjust the

tension of the belt. Tighten the locking nut

and the retaining bolt and check the tension

thus:

FORCE

LOCKING

NUT

DEFLECTION

RETAINING

BOLT

Belt Tensioning

7.2.3

V Belt tension is correct when the deflection

is 4mm with a force of 1.5kg applied at the

centre of the longest run.

Note: DO NOT OVERTIGHTEN BELTS

UNDER ANY CIRCUMSTANCES.

7.3 Mechanical Seals

7.3.1

Ensure that the coolant/lubricant level is

maintained. It is imperative that the seals

are never run dry. Immediate seal failure

will result.

7.3.2

Any contamination of the fluid should be

investigated immediately. Should a large

loss of fluid be experienced then the pump

must be stopped immediately.

7.3.3

Replacement of the seals is considered a

workshop operation where higher standards

of cleanliness can be maintained and the

specialised tooling required is more readily

available.

7.4 Mechanical Seal Removal

7.4.1

Remove the Tee piece and priming tank,

place oil tray under mechanical seal oil

drain plug to drain oil.

7.4.2

Remove the non-return valve and volute to

access the impeller. Unscrew impeller anti-

clockwise with the aid of a mallet until

undone, note the number of shims fitted

behind and retain for reuse.

7.4.3

Once the impeller is removed, remove the

rotating part of the primary mechanical seal

and remove rear wear plate. Then press

the seat out of the back wearplate.

7.4.4

Remove the circlip and washer off the shaft.

Then remove the secondary mechanical

seal and engine adaptor plate. Then press

out the seat.

7.4.5

Check the condition of the ’O’-rings and

replace if necessary.