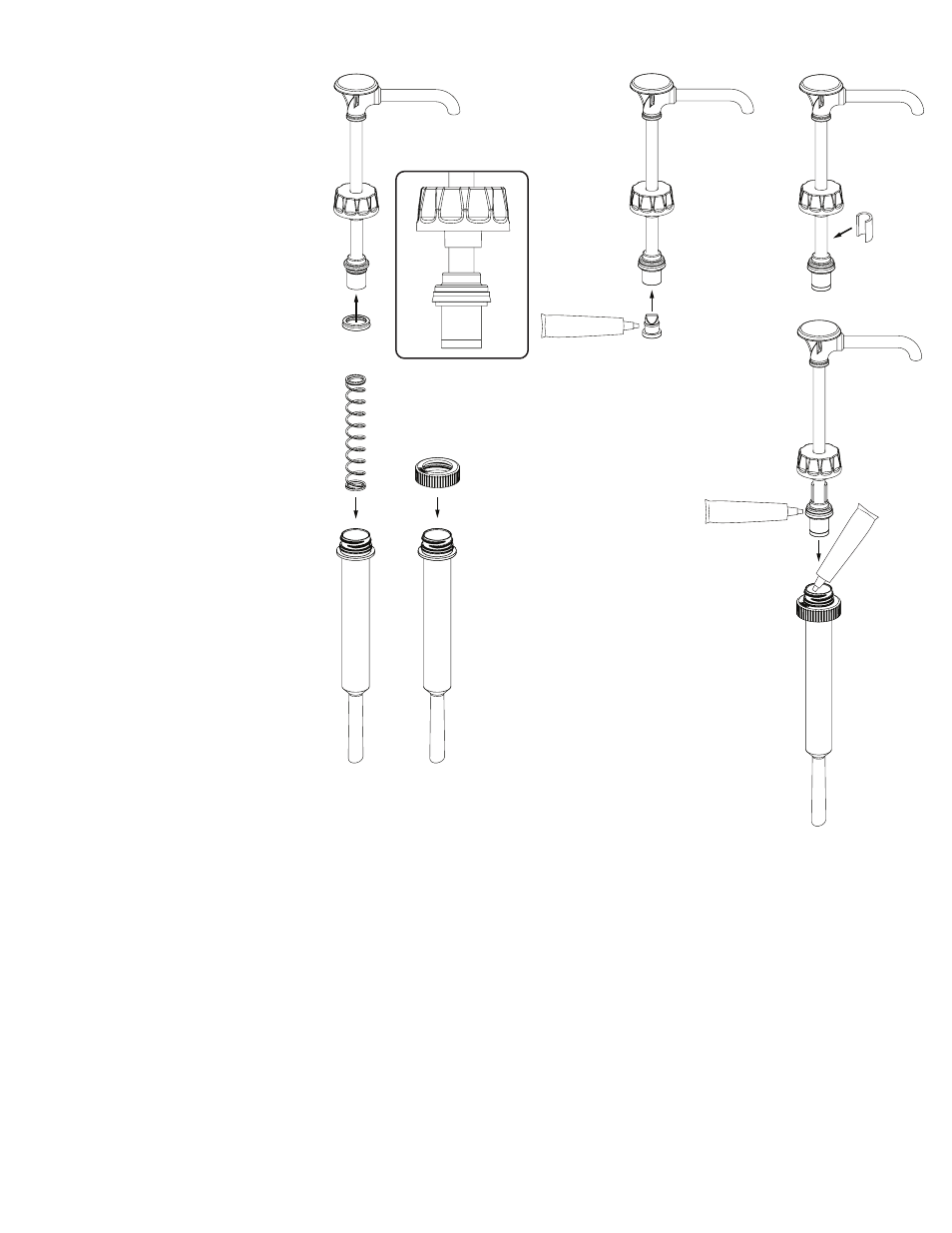

Pump assembly – Server PUMPS (88000/88573/88575) User Manual

Page 3

CLEAN INSIDE

DISCHARGE TUBE

CLEAN INSIDE

TAPERED END

OF DISCHARGE TUBE

PUMP ASSEMBLY

PUMP ASSEMBLY

ALWAYS CLEAN PUMP THOROUGHLY BEFORE EACH USE

AND AFTER USE DAILY. SEE PUMP DISASSEMBLY AND

PUMP CLEANING.

1

INSTALL SEAL SECURELY ONTO HEAD ASSEMBLY

PISTON.

• Apply food equipment lubricant inside seal.

• Flared end of seal assembly should be facing away

from piston head.

•

If seal is installed incorrectly, product will leak

past seal.

2

APPLY A SMALL AMOUNT OF FOOD EQUIPMENT

LUBRICANT INSIDE BOTTOM OF HEAD ASSEMBLY

PISTON. THEN INSTALL PINCH VALVE INTO BOTTOM

END OF HEAD ASSEMBLY PISTON.

•

Rotate pinch valve inside head assembly piston

to spread lubricant evenly inside end of head

assembly piston. Then position pinch valve

securely into a sealed position on end of head

assembly piston.

3

INSTALL GAGING COLLAR ONTO SIDE OF HEAD

ASSEMBLY PISTON.

4

INSTALL SPRING INTO CYLINDER.

5

INSTALL CAP BY SECURELY SNAPPING IT ONTO

CYLINDER, PAST THREADING.

6

SECURE CAP TO BOTTLE OR INSTALL LID BY SLIDING

LID UP FROM BOTTOM OF CYLINDER TO ALIGN

WITH CAP. SECURE PUMP TO BOTTLE OR LID BY

TIGHTENING CAP TO BOTTLE OR LID THREADING.

7

APPLY A SMALL AMOUNT OF FOOD EQUIPMENT

LUBRICANT INSIDE TOP OF CYLINDER AND TO

OUTSIDE SURFACE OF SEAL.

8

INSTALL HEAD ASSEMBLY PISTON INTO CYLINDER.

9

SLIDE LOCKING COLLAR DOWN ONTO CYLINDER

THREADING AND TIGHTEN TO SECURE HEAD

ASSEMBLY TO CYLINDER.

J

PREPARE PUMP FOR USE.

•

Operate pump several times until only product,

without air bubbles, is delivered with each stroke

of pump.