Pump cleaning, Clean-in-place procedure for pumps, Pump disassembly – Server PUMPS (88521/88200) User Manual

Page 2

PUMP CLEANING

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

STAINLESS STEEL PARTS CAN CORRODE.

IT IS IMPORTANT TO CLEAN, RINSE, SANITIZE, AND DRY

THESE PARTS DAILY AND PROPERLY.

FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1

SEE PUMP DISASSEMBLY.

2

WASH AND SCRUB ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER DAILY.

• Wash small parts in a pan or other container to

prevent part loss.

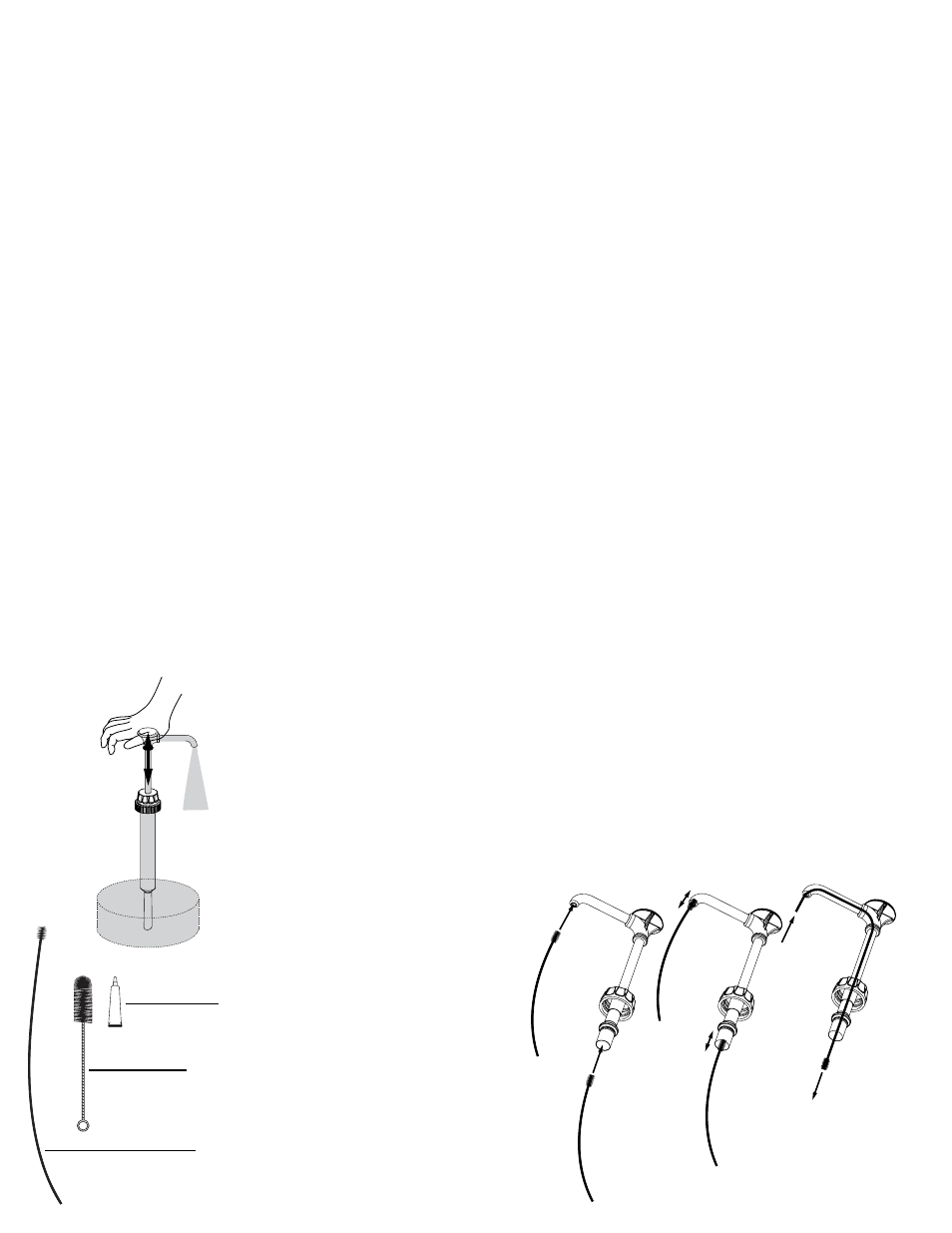

• Use supplied brushes to clean all confined

areas. Maintain a clean and efficient pump

by using the brushes supplied with pump to

prevent product build up inside pump.

• IMPORTANT PUMP AREAS TO CLEAN: Clean

inside cylinder thoroughly with brush 82049.

Clean inside discharge tube thoroughly with

brush 82526.

• Do not use abrasive cleansers, scrapers, steel pads,

steel wool, or other cleaning tools that can scratch

surfaces.

• A general purpose, nonabrasive cleaner may be used

on hard to remove food deposits.

• Do not use cleansing agents with high concentrations

of acid, alkaline or chlorine.

These agents can corrode stainless steel.

• Do not use ammonia to clean pump parts.

Ammonia can damage plastic parts.

• A nontoxic glass cleaner may be used for cleaning

any stainless steel parts.

3

FULLY RINSE ALL PARTS THOROUGHLY WITH CLEAR

WATER.

• Fully rinsing all parts can help prevent corrosion.

4

DRY ALL STAINLESS STEEL PARTS WITH A CLEAN

SOFT CLOTH.

• Various elements and minerals, such as chlorides in

tap water, can accumulate on stainless steel parts

and create corrosion.

• To prevent corrosion on any stainless steel parts, it is

important to fully dry with a clean soft cloth regularly.

5

SANITIZE PARTS FOLLOWING LOCAL SANITIZATION

REQUIREMENTS.

ALL PARTS IN CONTACT WITH FOOD MUST BE

SANITIZED.

• Allow parts to fully air dry after sanitization.

CLEAN AND FLUSH PUMP

WITH SOAP, SANITIZER, AND HOT WATER

CLEAN INSIDE

DISCHARGE TUBE

CLEAN INSIDE

TAPERED END

OF DISCHARGE TUBE

CLEAN-IN-PLACE PROCEDURE

FOR PUMPS

CLEAN-IN-PLACE IS A BASIC FOUR STEP PUMP FLUSHING

PROCESS: CLEAN, RINSE, SANITIZE, AND RINSE.

CLEAN:

1

PUMP OUT ALL (IF ANY) REMAINING FOOD PRODUCT

FROM INSIDE PUMP BODY.

2

WASH AND RINSE OFF OUTSIDE OF PUMP BODY.

3

FLUSH AND RINSE ALL INSIDE AND OUTSIDE

SURFACES OF PUMP THOROUGHLY WITH HOT WATER.

• Place lower end of pump into container of hot water

and operate pump until all (if any) remaining product

is expelled and only hot water flows from discharge

tube.

4

MIX 2 OZ (5 ML) OF DISHWASHING DETERGENT

(DAWN DISHWASHING LIQUID) WITH 1 QUART

(.95 L) OF HOT TAP WATER (APPROXIMATELY

110°F/43°C).

5

PLACE LOWER END OF PUMP INTO THIS CLEANING

MIXTURE AND REPEATEDLY OPERATE PUMP UNTIL ALL

CLEANING MIXTURE IS PUMPED THROUGH PUMP.

RINSE:

6

PLACE LOWER END OF PUMP INTO 2 CUPS (.5 L) OF

HOT TAP WATER (APPROXIMATELY 110°F/43°C) AND

REPEATEDLY OPERATE PUMP UNTIL ALL TAP WATER

IS PUMPED THROUGH PUMP.

SANITIZE:

7

MIX ONE 1 OZ (30 ML) PACKET OF KAY-5

SANITIZER/CLEANER (EPA REG NO. 5389-15) WITH

2.5 GALLONS (9.5 L) OF TAP WATER (APPROXIMATELY

ROOM TEMPERATURE).

8

PLACE LOWER END OF PUMP INTO THIS SANITIZING

MIXTURE AND REPEATEDLY OPERATE PUMP UNTIL

1 QUART (.95 L) SANITIZING MIXTURE IS PUMPED

THROUGH PUMP.

RINSE:

9

PLACE LOWER END OF PUMP INTO 1 CUP (.24 L) OF

HOT TAP WATER (APPROXIMATELY 110°F/43°C) AND

REPEATEDLY OPERATE PUMP UNTIL ALL TAP WATER IS

PUMPED THROUGH PUMP.

PUMP DISASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

DURING DISASSEMBLY, USE A CONTAINER TO COLLECT

SMALL PARTS OF PUMP TO PREVENT ANY LOSS.

1

LOOSEN CAP SECURING PUMP TO LID OR BOTTLE

AND REMOVE PUMP FROM LID OR BOTTLE.

.

2

LOOSEN LOCKING COLLAR AND REMOVE CYLINDER

ASSEMBLY FROM HEAD ASSEMBLY.

3

REMOVE SPRING FROM CYLINDER ASSEMBLY.

4

REMOVE PINCH VALVE FROM HEAD ASSEMBLY

• Pinch and gently turn to pull valve out.

5

REMOVE SEAL FROM HEAD ASSEMBLY BY PRESSING

DOWN AND OFF WITH THUMB.

•

Do not use a sharp tool to remove seal, this may

damage seal.

•

If seal is damaged, product will leak past seal.

6

REMOVE O-RING FROM INSIDE SEAL.

•

Do not use a sharp tool to remove o-ring, this may

damage o-ring.

•

If o-ring is damaged, product will leak past seal.

7

REMOVE GAGING COLLAR(S) FROM HEAD ASSEMBLY.

Food Equipment

Lubricant 40179

Brush 82049 (1 ¼” D)

Brush 82526 (21” D)