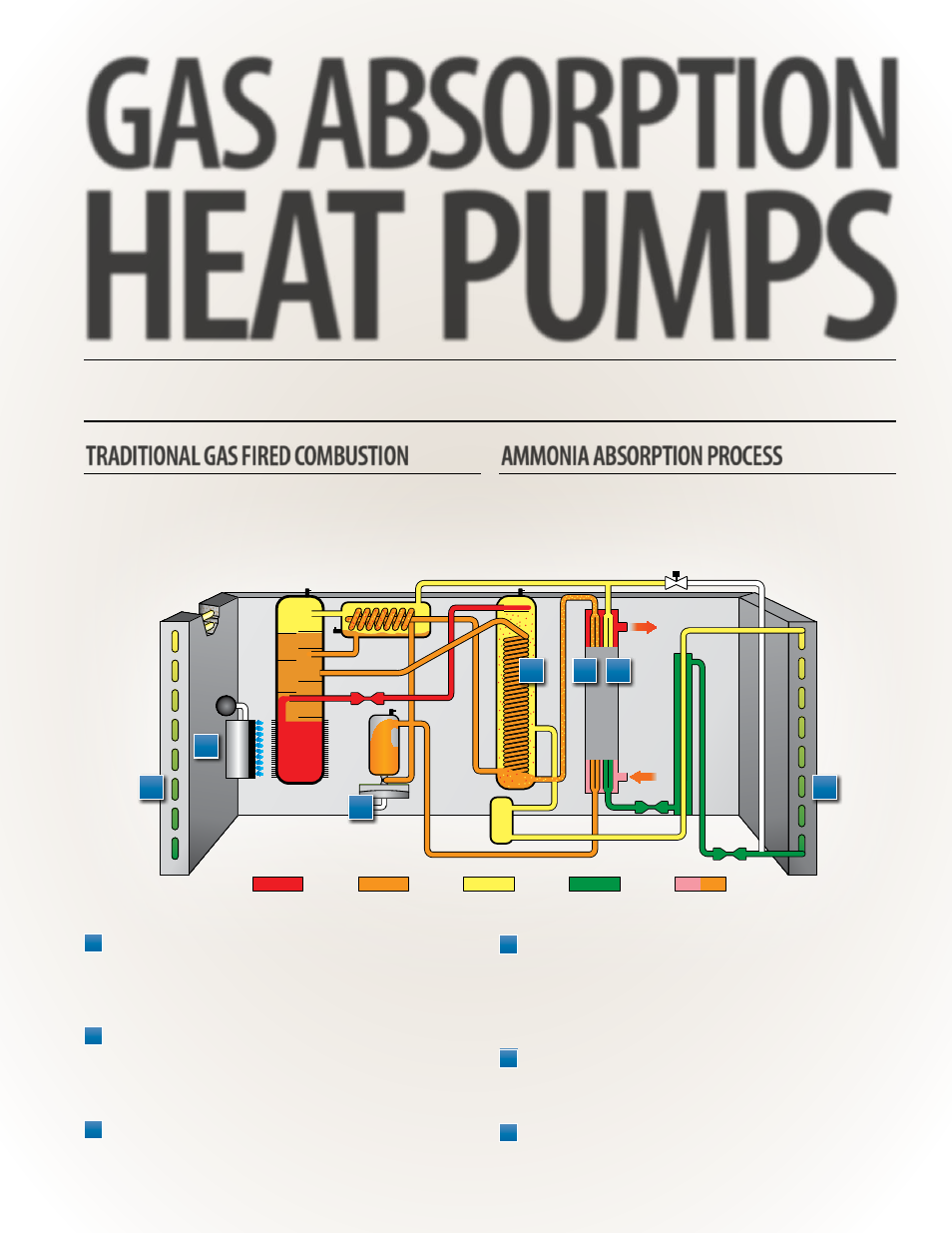

Heat pumps, Gas absorption, Traditional gas fired combustion – Fulton Invictus (IVS) Heat Pump Systems User Manual

Page 3: Ammonia absorption process

BURNER

GENER

AT

OR

RE-

GENER

AT

OR

EV

APOR

AT

OR

EV

APOR

AT

OR

ABSORBER

CONDENSER

PUMP

Water

104°F

Water/Ammonia

Solution

Vaporized

Ammonia

Liquid

Ammonia

Warm-Hot Hydronic

Loop Water

122°F

A

Natural gas or propane fired combustion heats up the

refrigerant solution contained in a chamber (generator).

The heat from combustion separates the ammonia and

water in the solution.

B

Heat is transferred to the hydronic loop as a result

of indirect contact with hot vaporized ammonia. The

ammonia changes phase from a vapor to a liquid as this

happens (condenses).

C

As the liquid ammonia travels through the finned coil

(evaporator), indirect contact with the outside air causes

the ammonia to vaporize.

TRADITIONAL GAS FIRED COMBUSTION

•

Natural Gas Fired Combustion

•

95,500 BTU/Hr Input per heat pump

•

Up to 142,600 BTU/Hr Output for heating

•

Up to 5.5 Tons for cooling

AMMONIA ABSORPTION PROCESS

•

Water-ammonia solution (R-717)

•

Ammonia is a natural and green refrigerant, with

ZERO Ozone Depletion Value and ZERO Global

Warming Potential Value

GAS ABSORPTION

HEAT PUMPS

TRADITIONAL GAS FIRED COMBUSTION

AMMONIA ABSORPTION PROCESS

Gas Absorption Heat Pumps combine gas fired combustion with a refrigerant interacting with

the environment. The heat pumps are hydronic, thus are used for heating or cooling water.

D

Water is introduced to vaporized ammonia, resulting

in a natural heat-producing exothermic reaction inside

a chamber (re-generator). This is where we obtain free

and renewable energy as a result of interacting with the

environment.

E

Heat is transferred to the hydronic loop as a result of

indirect contact hot water-ammonia solution created in

the re-generator.

F

A small pump moves the solution back to the

generator so the cycle can continue.

A

B

C

C

D

F

E

Demonstration:

Air Source Unit in Heating Mode