Installation – Fulton VMP Hot Water (VMPW) User Manual

Page 20

© The Fulton Companies 2012

INSTALLATION

VMPW-IOM-2012-1001

SECTION 2

2-14

operating temperature. Check all local codes for requirements.

The fl ue must be as large or larger than the outlet on the vessel. Avoid fl ue

piping and elbows by placing the equipment as close as possible to the chimney.

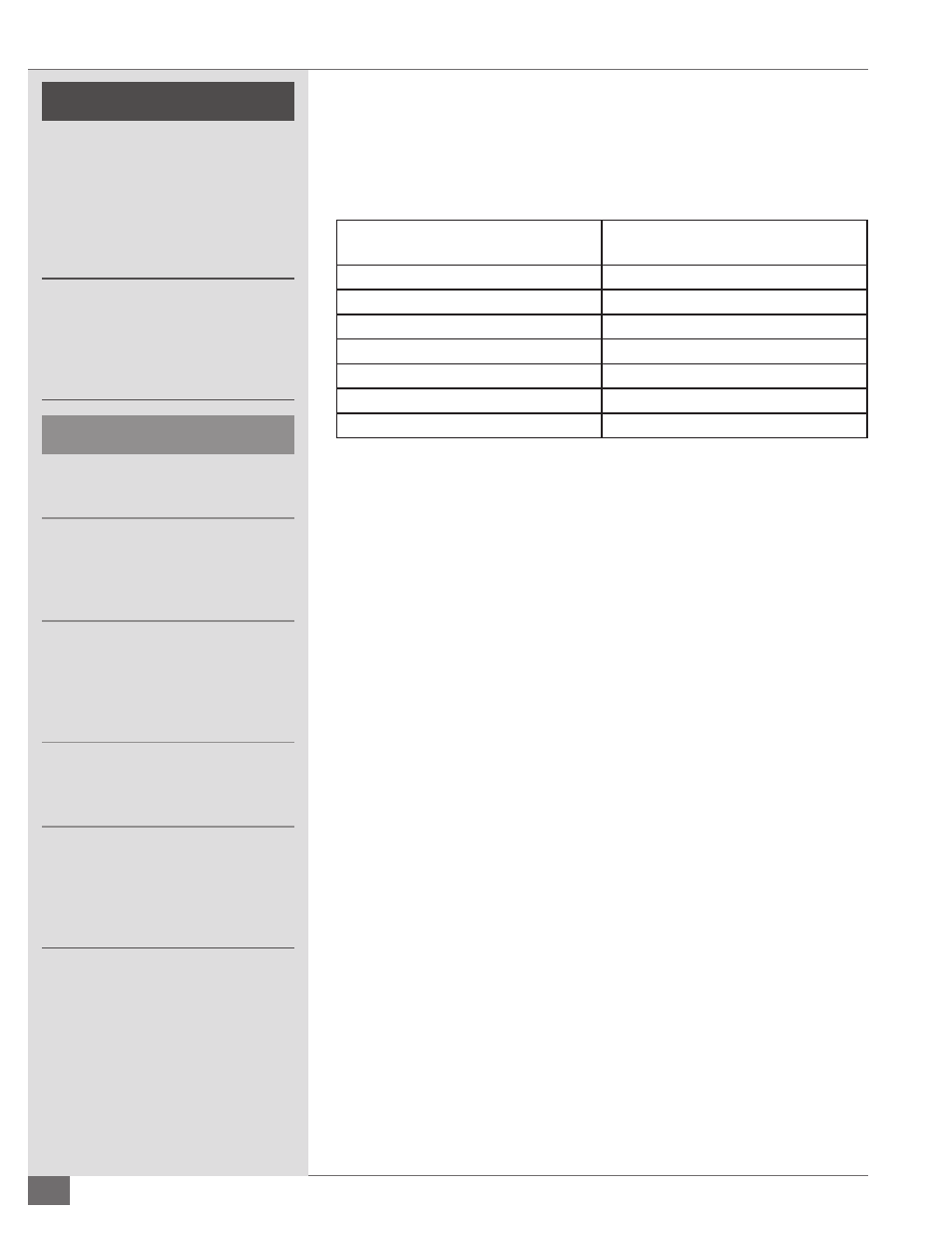

TABLE 4 - MINIMUM FLUE SIZES

Model

Minimum Flue Size

inches (mm)

40

12 (305)

50

12 (305)

60

12 (305)

80

14 (356)

100

14 (356)

130

14 (356)

150

16 (406)

Adhere to the following for stack and fl ue installation (see Figure 2):

1. Ensure the stack rises continuously to the connection at the chimney and

contains no more than two bends at 45 degree angles or less. If required,

as a result of space limitations, one 90 degree elbow (or tee) can be fi tted

at the back of the vessel.

2. Ensure 2 feet (0.6 m) of straight, horizontal fl ue before any change in

direction, fi tting or draft regulator. This is to prevent potential pilot or

main fl ame failures due to back pressure build up during ignition. Any

alternative stack arrangement must supply negative 0.02 to 0.04”wc.

3. Ensure the run in the total distance of stack ducting, as measured in a

straight line from the outlet of the boiler to the outlet of the stack, does

not exceed 25% of the rise. With the exception of the duct run previously

described, horizontal sections of ducting must be avoided and should not

exceed 4 feet (1.2 m) total. See Figure 2.

4. Ensure the stack, chimney, and any components associated with the stack,

such as heat reclaimers or assist fans, are constructed from material that is

rated for a 1000 F (538 C) operating temperature.

5. Ensure the stack and chimney material complies with all applicable codes.

6. Make adequate provisions for the support of the weight of the chimney

and stack to avoid having a load imparted to the outlet connection of the

equipment.

7. Ensure the draft, when fi ring, is negative and constant. A reading of -0.02

to -0.04”wc (-0.508 to -1.016 mm) when the unit and stack are cold usually

indicates suffi

cient draft. When the unit is running and the stack is hot, the

draft should read -0.04 to -0.08 “wc (-1.016 to -1.524 mm) negative.

8. The installation of a draft regulator by the client/contractor is

recommended at all installations. This will help to maintain the required

draft. The placement of the draft regulator should be as shown in Figure 3.

Insulate the section of the chimney duct within the building.

ã

WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Non-Fulton product information is for

reference purposes only. No Fulton

document may substitute for full

review of documentation available

from the component manufacturer.

Ð

CAUTION

Boilers damaged due to adverse water

conditions are not covered by warranty.

The weight of all piping must be

properly supported. Failure to support

piping may result in equipment

damage and/or system leakage.

Piping must take into consideration

potential for freezing interference and/

or damage as a result of expansion,

contraction, vibration, or other

movements.

Dirt, water, and/or other debris in the

piping system after welding may result

in equipment failure.

To maintain a reasonable

temperature in the equipment area

and ensure safety to personnel, the

section of the chimney duct within

the building should be insulated.