Installation, Utilities, The gas supply – Fulton VMP Hot Water (VMPW) User Manual

Page 12

© The Fulton Companies 2012

INSTALLATION

VMPW-IOM-2012-1001

SECTION 2

2-6

3. See Table 3 for minimum make up air openings required

for each model.

TABLE 3- MINIMUM MAKE UP AIR OPENING REQUIREMENTS

Model

Fresh Air Opening FT2 (M2)

40

1 (.09)

50

1 (.09)

60

1.5 (.14)

80

4 (.37)

100

4 (.37)

130

5 (.46)

150

7.5 (.69)

4. If positive forced ventilation is adopted, ensure that

there will be no appreciable pressure variation in the

equipment room.

5. Avoid ventilation which creates a negative pressure

in the building as it will seriously aff ect combustion

and proper operation of the burner. Please note that

exhaust fans or similar equipment can create a down

draft in the chimney or starve the burner’s air supply.

Either case may result in poor combustion or nuisance

failures. A properly designed make-up air system in the

equipment room will preclude these possibilities and is

required to maintain proper combustion.

6. Eliminate potential for high risk situations for particulate

matter to be in the combustion air supply (e.g., as a

result of construction and maintenance activities).

Utilities

The Gas Supply

Adhere to the following for gas supply installation:

1. Install gas piping in accordance with all applicable

codes.

2. Ensure pipe and fi ttings used are new and free of dirt or

other deposits.

3. Ensure piping is of the proper size for adequate gas

supply to the gas head assembly. Consult your gas

company for specifi c recommendations.

4. When making gas piping joints, use a sealing

compound resistant to the action of liquefi ed

petroleum gases. Do not use Tefl on tape on gas line

heads.

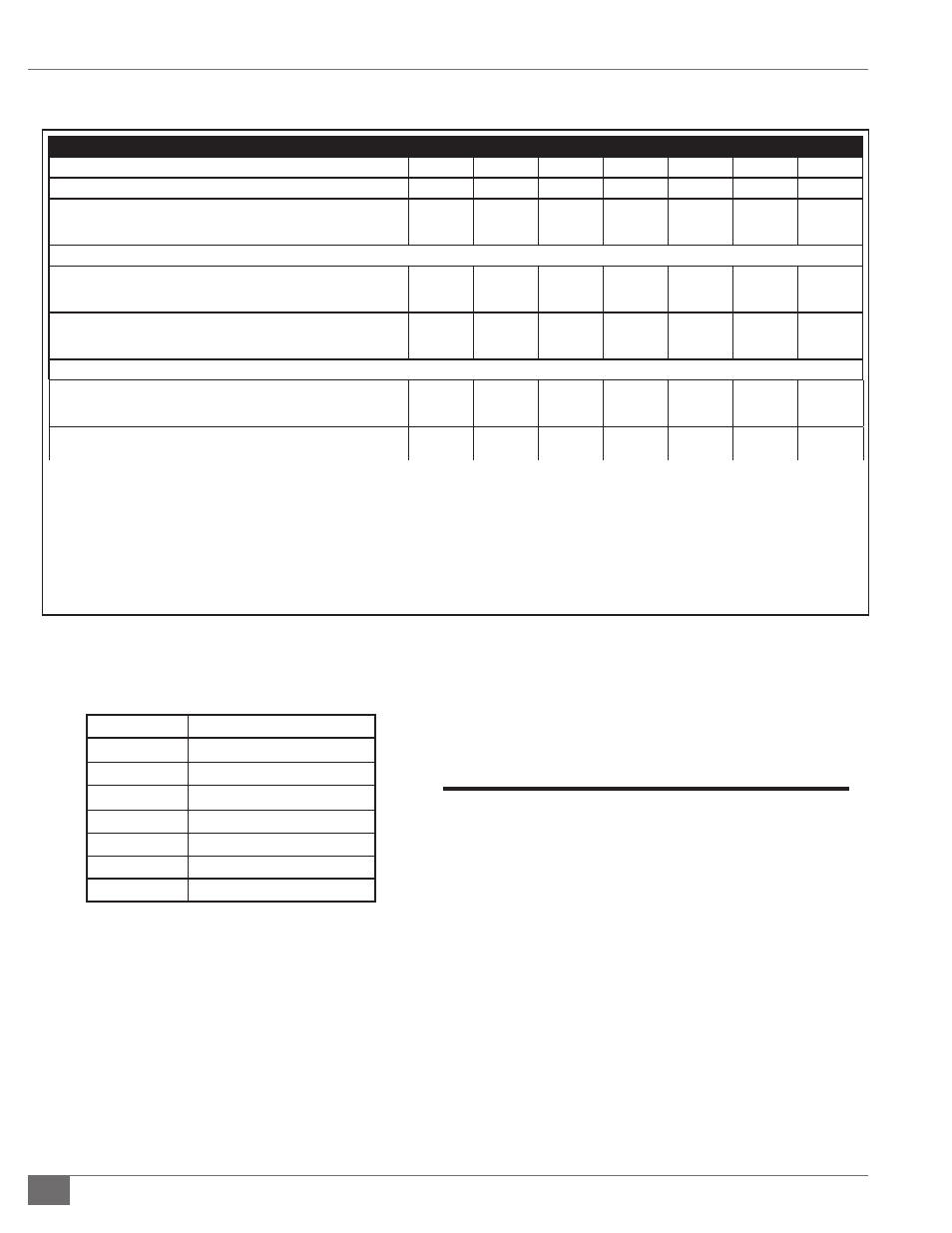

Model VMP-W Low Emissions (LE) MOTOR

Model VMP-WModel

40

50

60

80

100

130

150

Model VMP-W

40

50

60

80

100

130

150

Burner Motor **

HP

WaƩ s

5

3730

5

3730

5

3730

5

3730

5

3730

Consult

Factory

Consult

Factory

Approximate Weights

Shipping Weight

LB

KG

6575

2982

7373

3345

8170

3706

8800

3992

10300

4672

12800

5806

12800

5806

OperaƟ ng Weight

LB

KG

8659

3928

9684

4393

10671

4840

12051

5466

14700

6668

20585

9337

20585

9337

Approximate Fuel ConsumpƟ on at Rated Capacity+

Natural Gas

FT

3

M

3

1595

45

1992

56

2392

68

3188

90

3985

113

5182

147

5978

169

Required Gas Pressure (IN. W.C./PSIG)

Minimum/Maximum

30/10

30/10

40/10

40/10

40/10

60/10

60/10

208V, 60 CY, 3 Phase

16.7

16.7

16.7

16.7

24.2

Consult Factory

230V 60 CY 3 Phase

15.2

15.2

15.2

15.2

22

Consult Factory

460V 60 CY 3 Phase

7.6

7.6

7.6

7.6

11

Consult Factory

Specifi caƟ ons and dimensions are approximate. We reserve the right to change data without prior noƟ fi caƟ on.

Design condiƟ ons based on 160 F return and 180 F supply.

+ ConsumpƟ on based on natural gas 1000 Btu/Ō 3.

** Sub 20 ppm; for lower requirements, consult factory.