Installation, Important – Poweramp TPR SERIES User Manual

Page 13

11

4111-0035 — Feb 2012

Aug 2012

INSTALLATION

Post safety warnings and barricade the work area at

dock level and ground level to prevent unauthorized

use of the dock leveler before installation has been

completed.

Failure to follow the installation instructions can

result in damage to dock leveler, the facilities, and/

or serious personal injury or death.

IMPORTANT

DO NOT connect the dock leveler electrical wiring

and ground connections until all welding has been

completed.

DO NOT ground welding equipment to any hydraulic

or electrical components of the dock leveler. Always

ground welding equipment to the dock leveler frame,

NEVER to the platform.

Failure to follow these instructions may damage the

motor, hoist cylinder, wiring, and/or control panel.

11

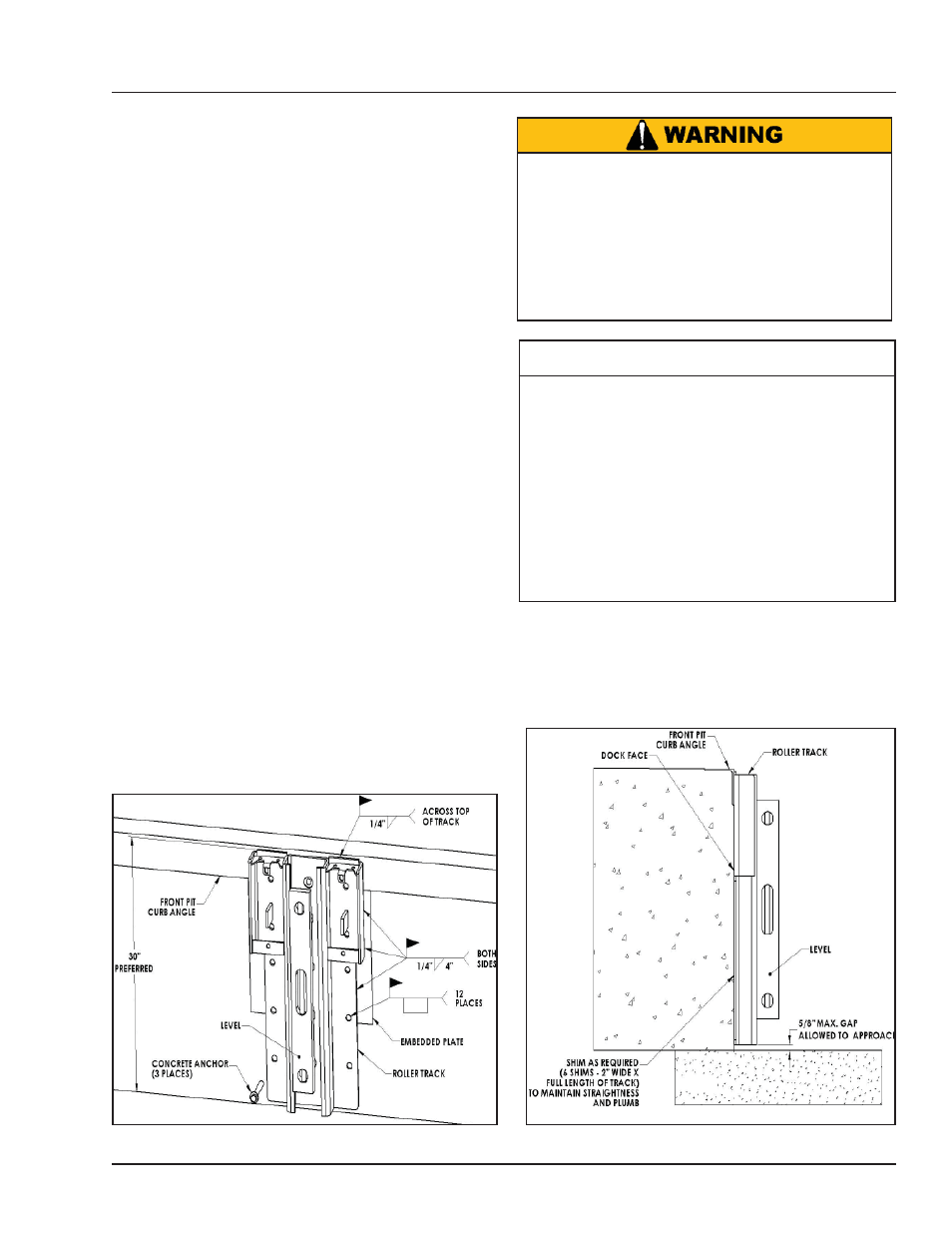

WELDING INSTALLATION INSTRUCTIONS

If the installation being worked on is a retrofit

or replacement situation, the following electrical

connections must be disconnected prior to welding:

LOCKOUT/TAGOUT the power at the fused

disconnect, then remove the motor and limit switch

connections from the control harness located in the

outside junction box. Once all welding has been

completed, reconnect all the wires.

NOTES:

1. NEVER install the TPR vehicle restraint directly

onto concrete block or brick dock face.

2. When welding the TPR vehicle restraint,

disconnect power and ground leads to leveler.

3. Due to actual conditions, total mounting height

may be different.

4. Plug weld all holes that are in contact with the

embedded mounting plate. All fifteen (15) holes

must be either plug welded or anchored.

5. Shims must be the full length of the roller track

mounting plate. Minimum electrode must be 1/8"

7018 or better.