Troubleshooting, Ending the cut – Diamond Products WS25 User Manual

Page 9

Page 9

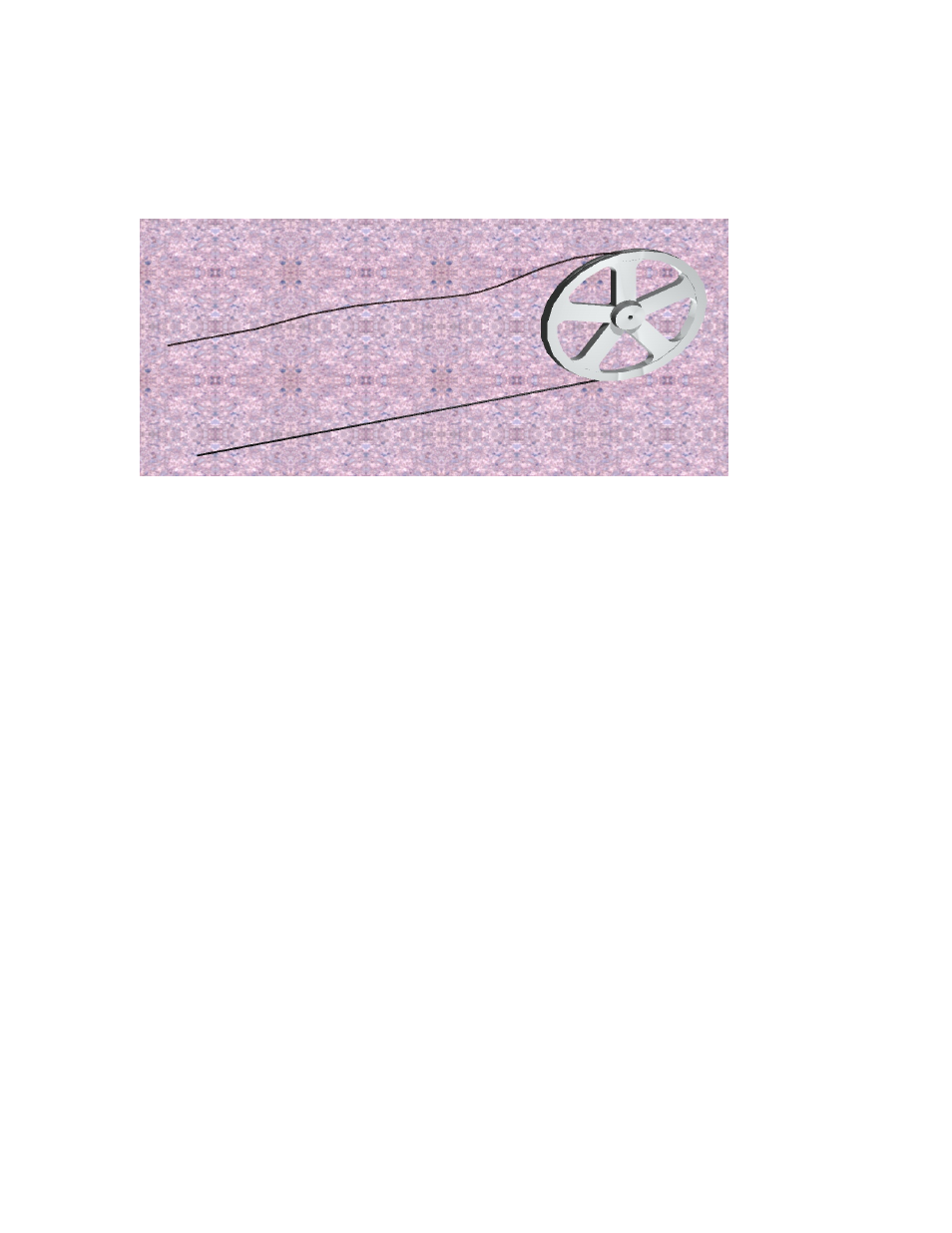

Proper tension is important. This can be visually verified; you should see a slight

wave in the slack side of the wire during cutting (FIG. 11).

FIG. 11

Ending the cut

As you start to get close to the end of the cut, shim the cut with steel shims to

avoid pinching the wire during the cutting operation and when the cut is

complete. Ensure that pulleys are set up so they can catch the wire when it exits

the cut.

Troubleshooting

Problem Possible

Cause

Solution

Cable will not start

Too much cable tension

Reduce feed force

Cable thickness variation

Check cable for uniform diameter

New cable in a narrow cut

Open cut to clear wire

Hanging up on corner

Round off edges

Cable locks up in cut

Cable overloaded

Reduce feed force

Hanging up on corner

Round off edges

Cut not straight

Not enough diverter pulleys

Add more pulleys and check alignment

Cable too slack

Increase feed force

Pulley misaligned or loose

Check pulley alignment

Uneven wear

Not enough pre-twist in wire

Ensure that there is at least 1 twist for

every 3 feet.

Cable over tensioned

Reduce feed force

Drive wheel and cable too close Increase spacing between saw and

pulley.

Misaligned pulley

Align pulleys