Chapter 5 – Diamond Products CC1600 User Manual

Page 12

Chapter 5

TROUBLESHOOTING

1. If your saw does not operate properly, the following table may be used as a guide in

diagnosing and eliminating the problem. If you cannot fix it using this table, call our

service representative.

2. Before calling, be sure you can describe the problem clearly so our representative can

help you. Have this manual at hand.

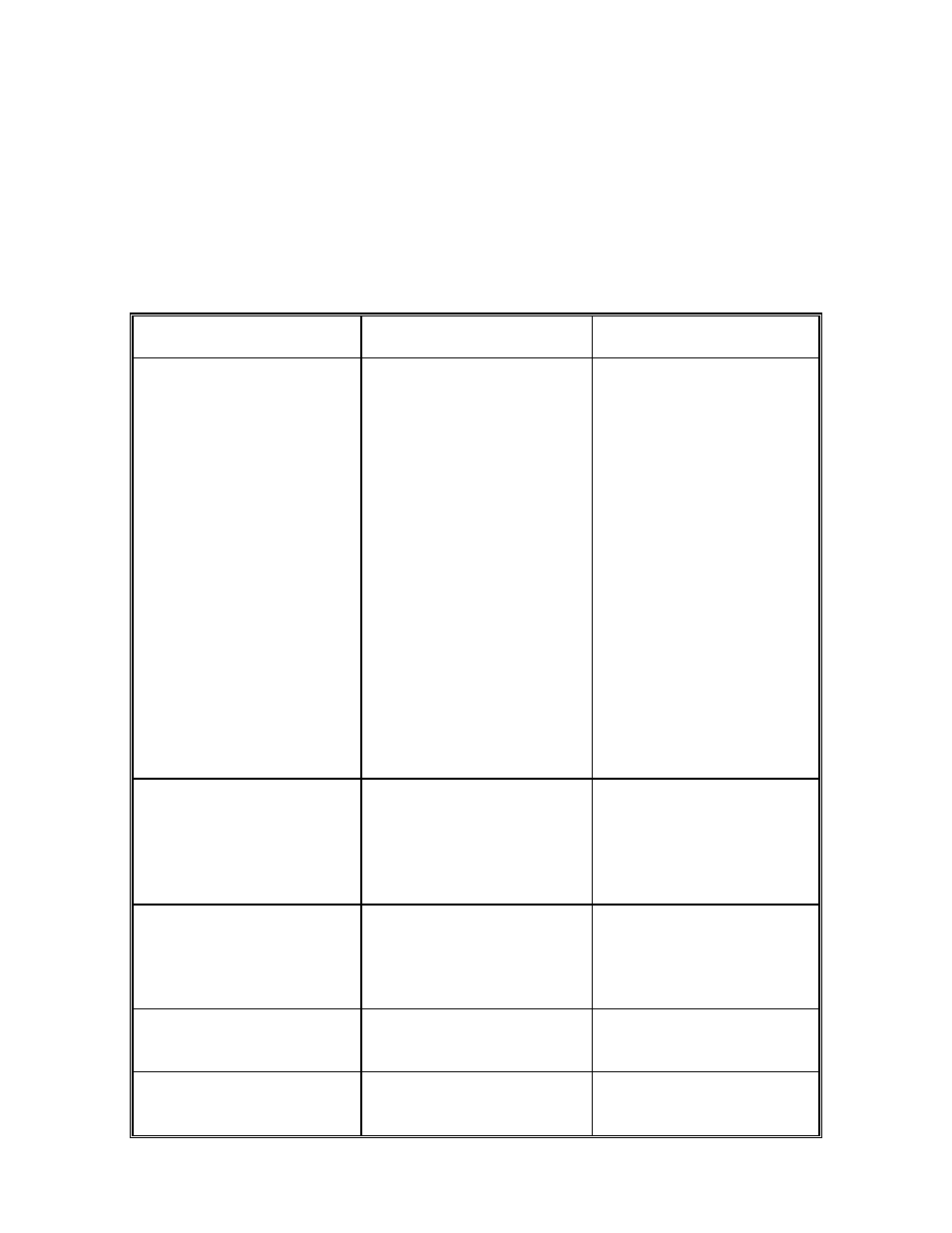

TROUBLE CAUSE REMEDY

Saw does not move or

moves erratically.

Rollers or slides out of

adjustment.

Rack is dirty.

Loose nut on Blade

Depth Control

Assembly

Loose nut on Manual

Travel Assembly

Travel Transfer

Assembly worm gear

mis-aligned.

Adjust rollers and

slides.

Clean rack.

Remove assembly and

tighten nut using

loctite 262

Same as above

Remove assembly,

slide worm gear

against bearing and

tighten setscrew.

Blade drive pressure

fluctuates.

Speed of motor is too

low.

Power unit is defective.

Change to a smaller

motor or increase

GPM.

Check power unit.

Blade does not rotate

when valve is opened.

Blade is jammed in

cut.

Power unit is defective.

Remove blade from cut

and try again.

Check power unit.

Saw motor leaks.

Motor seals are

defective.

Replace motor or

motor seal.

Coupling leaks.

Coupling is defective.

Replace coupling or

coupling seal.