Morris Pipe and Tube Bends User Manual

Pipe and tube bends, Morris pipe and tubing straights, Tube bending capabilities

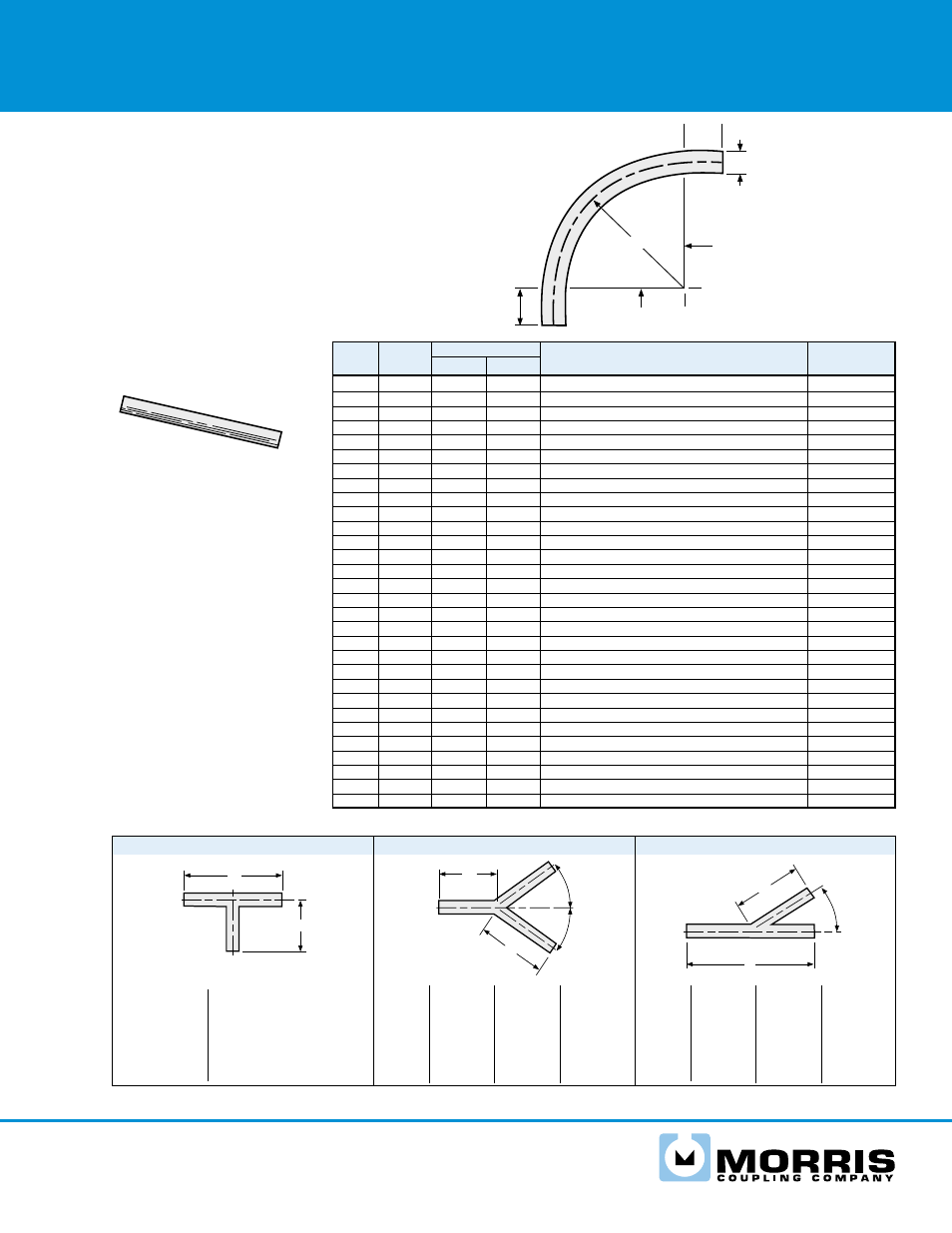

D

C

19

2240 W. 15th St., Erie, PA 16505

Phone: 814-459-1741

For Prices and Delivery

Call Toll Free: 1-800-426-1579

Toll-Free Fax: 1-800-545-1399

E-mail: [email protected]

internet: www.morriscoupling.com

Pipe and Tube Bends

for pneumatic systems, short and long radius

Morris Pipe and

Tubing Straights

Straight lengths of pipe and tubing

are available in carbon steel,

aluminum, and stainless –

1-1⁄2" O.D. thru 10" pipe in

a variety of wall thicknesses.

ORDER BENDS by O.D., wall thickness,

alloy, degree of bend, centerline radius and

tangent.

WALL THICKNESS: 16 ga. (.063), 14 ga.

(.083), and 11 ga. (.120) in tubing.

Schedules 5, 10 and 40 pipe. Other wall

thicknesses

on request.

*Carbon Steel, Schedule 40 Only.

MATERIALS: Aluminum is 6063-T1

extruded. Stainless is T304 ASTM A312

for Pipe and T304 ASTM A249 for tubing.

Carbon steel ASTM A53 for pipe; A513

for tubing. Galvanized A53 for galvanized

coated. Pipe and A513 for galvanized-

coated tubing.

OD

A

B

2"

16"

8"

3"

16"

8"

4"

16"

8"

4-1/2"

18"

9"

5"

18"

9"

6"

20"

10"

8"

24"

12"

OD

30°

45°

60°

C

D

C

D

C

D

2"

8"

8"

8"

8"

8"

8"

3"

8"

8"

8"

8"

8"

8"

4"

8"

8"

8"

8"

8"

8"

4-1/2"

10"

10"

10"

10"

10"

10"

5"

11"

11"

11"

11"

11"

11"

6"

12"

12"

12"

12"

12"

12"

8"

14"

14"

14"

14"

14"

14"

OD

30°

45°

60°

E

F

E

F

E

F

2"

8"

16"

8"

16"

8"

16"

3"

10"

20"

8"

16"

8"

16"

4"

12"

24"

10"

20"

10"

20"

4-1/2" 12"

24"

10"

20"

10"

20"

5"

15"

30"

12"

24"

12"

24"

6"

18"

36"

15"

30"

15"

30"

8"

22"

40"

18"

36"

18"

36"

ORDER TEES by tube or pipe size, wall thickness, and metal.

O.D.s not listed, available on request.

ORDER LATERALS and WYES by tube or pipe size, wall thickness, metal and degree of angle.

Tube

Pipe

Outside Diameter

Common Centerline

Std. Tangent

Size

Size

inches

mm

Radii (CLR) Inches

(ST)

1"

1.0

25.4

3, 4, 6, 12

4"

1"

1.315

33.4

3, 5

4"

1-1/4"

1.25

31.8

3, 7.25

4"

1-1/4"

1.660

42.2

3.5, 4, 6.25

4"

1-1/2"

1.5

38.1

2.5, 6, 7.5, 9, 12, 15, 18, 24, 30, 36

4"

1-3/4"

1.75

44.5

2.5, 8, 9, 12, 15, 24, 30, 36, 48

4"

1-1/2"

1.9

48.3

5, 6, 7.5, 9, 10, 12, 18, 24, 30, 36, 48

4"

2"

2.0

50.8

2.5, 5, 6, 8, 8.5, 9, 10, 12, 15, 18, 24, 30, 36, 48

4"

2-1/8"

2.125

54.0

5, 12, 24, 30, 36

4-1/4"

2-1/4"

2.25

57.2

3, 9, 12, 15, 17, 24, 30, 36

4-1/2"

2"

2.375

60.2

6, 7.5, 9, 10, 12, 15, 17, 24, 30, 36, 48

4"

2-1/2"

2.5

63.5

4, 6, 9, 12, 15, 17, 24, 30, 36, 48

5"

2-3/4"

2.75

69.9

17, 30, 36, 48

5-1/2"

2-1/2"

2.875

73.0

12, 12.5, 15, 17, 24, 30, 36, 60

5"

3"

3.0

76.2

4.5, 7.5, 9, 10, 12, 15, 18, 24, 30, 36, 48, 60

6"

3-1/4"

3.25

82.6

17, 30, 36

6-1/2"

3-1/2"

3"

3.5

88.9

3.5, 6, 8.75, 12, 15, 16, 18, 24, 30, 36, 48

7" (6" - pipe)

3-3/4"

3.75

95.3

17, 24, 32, 36

7-1/2"

4"

3-1/2"

4.0

101.6

6, 10, 12, 16, 18, 20, 24, 30, 32, 36, 48, 60

8" (7" - pipe)

4-1/4"

4.25

107.9

16, 30, 36, 48, 60

8-1/2"

4-1/2"

4"

4.5

114.3

6, 9, 12, 16, 18, 20, 24, 30, 32, 36, 48, 60

9" (8" - pipe)

4-3/4"

4.75

120.7

36

9-1/2"

5"

5.0

127.0

7.5, 12.5, 17, 22, 24, 30, 36, 42, 48, 60

10"

5"

5.563

141.3

15, 20, 24, 30, 36, 42, 48, 60, 72

10"

5-1/2"

5.5

139.7

30, 36

11"

6"

6.0

152.4

9, 15, 18, 24, 30, 36, 42, 48, 60, 72

12"

6"

6.625

168.2

18, 24, 30, 36, 42, 48, 60, 72

12"

8"

8.0

203.2

12, 20, 32, 48, 60, 72

16"

8"

8.625

219.1

24, 32, 40, 48, 60, 72

16"

10"

10.75

273.1

40, 50

20"

Tube Bending Capabilities

Pipe and tube bends of up to 180° are readily available in

aluminum, stainless, carbon steel and galvanized in the

sizes listed. Other centerline radii are available but not

shown. Special shapes, ‘U’ bends, offsets, and bifurcat-

ed bends available upon request.

Morris tube bends are manufactured in our Knoxville,

Tennessee, Plant.

ST

O.D.

CLR

S

T

d = Degrees Bend Angle

A

B

F

E

TEES

WYES

LATERALS

Capabilities subject to change without notice.