Mody Pumps MS 252 User Manual

Page 9

Low Voltage Products & Systems

1.1

11

0

4

S

05.03.04

Liquid Level Control

Application Notes

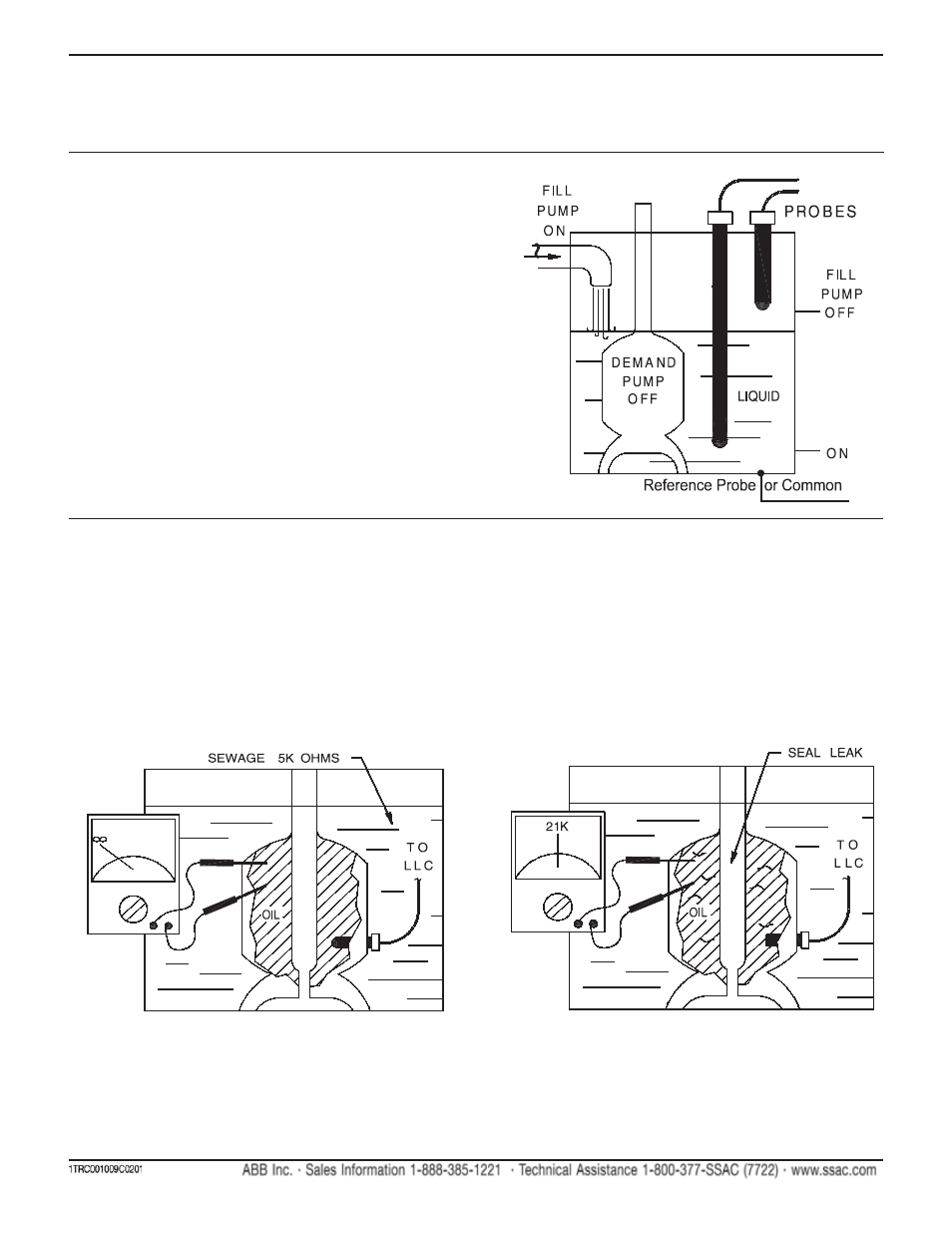

Another use for a conductive liquid level control is as a seal

leak detector. An electrode is placed in contact with the

non-conductive oil within a pump/motor casing. If a leak in a

watertight seal occurs, the conductive contaminates introduced

into the oil lowers its resistance. The LLC senses this change in

resistance. The example in Figure 4A & 4B illustrates a typical

sewage pump application. The probe is normally inserted through

a watertight seal which isolates the probe from the case (common

connection). A separate wire runs from the pump ground (case)

to the LLC common to complete the sensing path. Typical

sewage has a resistance of 5K ohms. An LLC setting, of ap-

proximately 21K ohms, will allow detection of minute levels of

sewage in the oil. This means leaks are detected early. Normally

the output of the LLC would then be connected to an alarm to

signal a leak has occurred allowing routine maintenance to be

scheduled to replace the damaged seal.

Figure 4A

Figure 4B

Dual Probe Level Control

Seal Leak Detection

Figure 3

The dual probe input LLC’s are designed to maintain the high or

low level of a liquid within the containment tank. Figure 3 is an

example of a water well reservoir application. Using an LLC2

Series open board design or the LLC5 series 8 pin plug-in (with

the ‘B’ fill logic), we will be able to maintain a precise level within

the holding vessel.

As long as the potable water (with a typical resistance of 5K ohms)

remains in constant contact with and completes the path between

the upper and lower probes, the LLC’s output remains de-ener-

gized. During usage, the demand pump lowers the water level.

When the water level drops below the lower probe, the LLC’s out-

put energizes and closes the fill pump control circuit.

As the level rises, the pump up circuit will remain closed until the

water rises to and touches the upper probe. With the probe depths

set accurately, the high level of the tank is maintained and the low

level will not drop below the intake of the submersible pump, thus

avoiding a loss of prime condition.