Meriam 70H_72H High Pressure Wet Tap Accutubes with Integral 3-Valve Head and Optional RTD User Manual

Page 9

9

2

OPERATIONAL CONSIDERATIONS

2.1

The Accutube flow sensor is a bi-directional flow meter. It can measure flow in either

direction. The Accutube head is labeled High and Low pressure as observed for normal

flow directions. With reverse flow, the High-pressure signal will occur at the Low-

pressure port and vice versa. Reverse flow measurement is as precise as forward flow.

This unique feature allows measurement of flow that changes direction. Special

consideration should be given to the indicating instrument. Instruments which allow

positive and negative (zero center) differential pressure readings are best applied here.

2.2

Accutube probes have limits as to the maximum flow rate that can be tolerated without

risking damage to the sensor. The limits are defined as the maximum allowable

differential pressure. See the Accutube general catalog which lists the maximum

allowable differential pressures for your Accutube model.

2.3

Installation of the Accutube in locations where significant pipe vibrations exist should be

avoided. Double mount style Accutubes are recommended where vibration is a concern.

3

READOUT INSTRUMENTATION

3.1

Many types of readout instrumentation can be used to measure the Accutube differential

pressure. The most common types are manometers, dial gauge indicators, electronic

transmitters/transducers or electronic gauges. Each type has its own installation and

operational characteristics. Refer to manufacturer’s manuals for installation instructions.

3.2

Mounting position can affect zero indication on certain types of instruments. In such

cases, the zero setting should be adjusted after installation of the instrument.

3.3

When a mercury manometer is used with a steam or liquid flow a correction factor must

be applied to the flow calculations. Refer to Handbook, File No. 957:081, for

determining the correction factor.

4

INSTALLATION PROCEDURE

4.1

GENERAL REQUIREMENTS

4.1.1

Prepare the surface of the pipe or duct where the Accutube is to be mounted.

Proper preparation involves removal of scale, rust, paint and grease for proper

welding of the threaded coupling.

4.1.2

Drill or burn a hole through the pipe at the mounting location. The hole should

be 1/16" to 1/8" larger than the probe diameter as identified in Table 4.

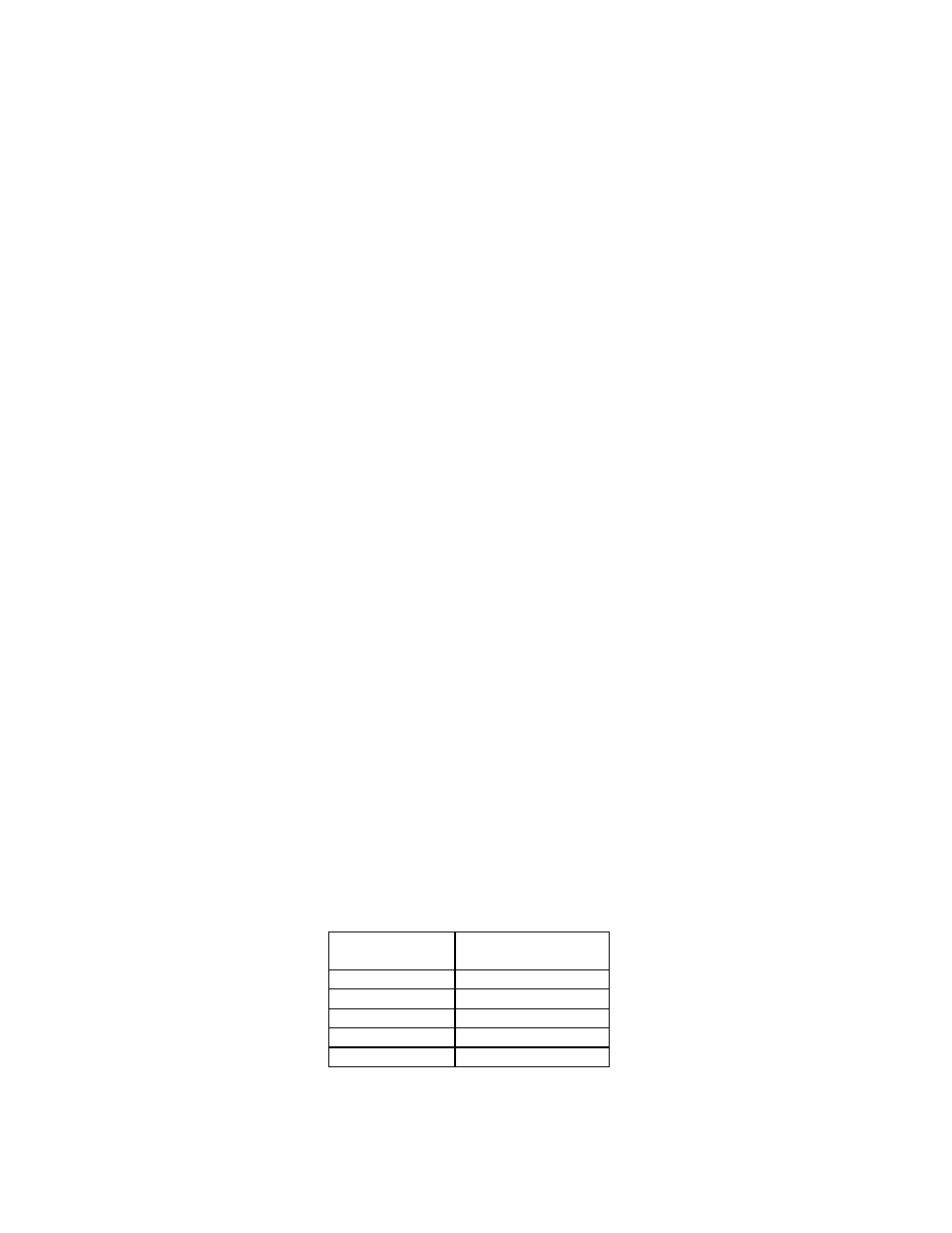

TABLE 4

PROBE

DIAMETER

RECOMMENDED

DRILL SIZE

3/8

7/16

1/2

9/16

3/4

13/16

1

1-1/16

2-3/8

2-1/2

- 40H to 43H Insertion Accutube with Integral 3-Valve Head 33T Low Pressure Accutube and Wet Tap Mounting Assemblies 37L High pressure Wet Tap Accutube 24D_25D Flange Mount Accutube 22L_23L High Pressure, Insertion Type Accutube 20T_21T Low Pressure, Insertion Type Accutube 10 A_11A Inline Type Accutube