Meriam 70H_72H High Pressure Wet Tap Accutubes with Integral 3-Valve Head and Optional RTD User Manual

Page 10

10

4.1.3

Double support type sensors require a second hole on the opposite side of the

pipe. Location of this hole is important as it establishes proper alignment of the

probe with respect to the flow. A common method of locating the opposite

support hole is by wrapping a piece of string totally around the pipe, with the

string crossing square to the pipe. The position can be marked at 1/2 the total

length of the string.

4.1.4

Center the threaded weld coupling over the hole and tack weld in place.

4.1.5

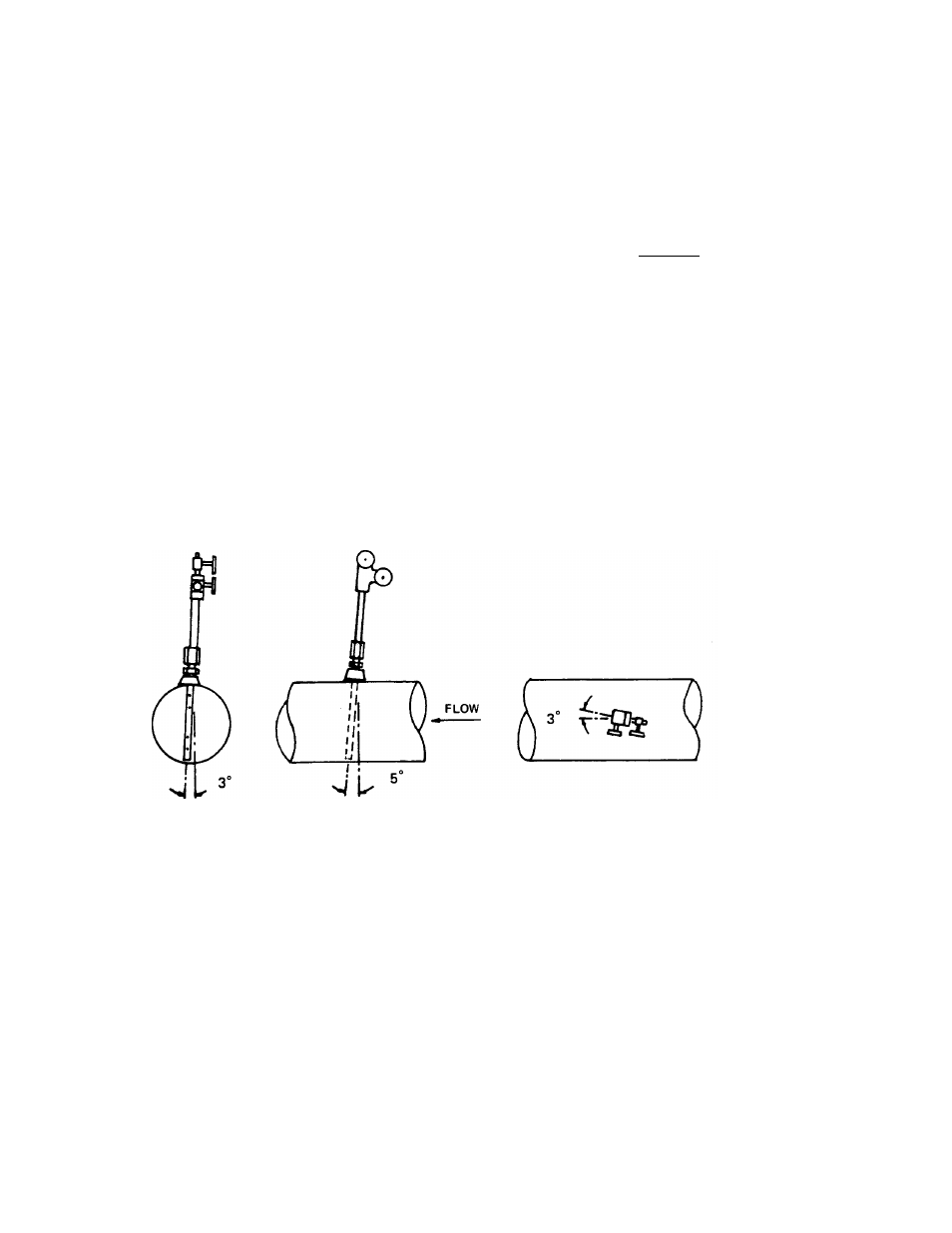

Thread the packing gland fitting in place (compression type), and insert the

probe into the pipe. Observe the position of the probe assuring that it is

perpendicular within the tolerance shown in Figure 4.1. If adjustments are

required, remove the probe and packing, and thread a pipe into the threaded

fitting a few feet long. With the leverage of the pipe force the threaded fitting

into the proper position.

DO NOT TRY TO USE THE ACCUTUBE AS A LEVER. DAMAGE TO THE

PROBE AND/OR PACKING CAN RESULT!

4.1.6

Once alignment is verified, perform a final weld of the threaded fitting.

4.1.7

Re-assemble the packing and insert the Accutube as described in Section 4.3.

FIGURE 4.1 ACCUTUBE PROBE POSITIONING

(Maximum Allowable Misalignment)

4.2

INLINE FLOW SENSORS: SERIES 10A, 11A & 12A

4.2.1

The inline series flow sensors are flow-through devices in which the line must

be interrupted for the device to be installed.

4.2.2

Positioning of the sensor is the same as recommended for the other types of

sensors as listed in Section 1.0.

4.2.3

Connections to the main line are made through either threaded pipe fittings,

solvent cement for PVC plain end type, hose connections for plain end types, or

soldered joint for copper tube units.

- 40H to 43H Insertion Accutube with Integral 3-Valve Head 33T Low Pressure Accutube and Wet Tap Mounting Assemblies 37L High pressure Wet Tap Accutube 24D_25D Flange Mount Accutube 22L_23L High Pressure, Insertion Type Accutube 20T_21T Low Pressure, Insertion Type Accutube 10 A_11A Inline Type Accutube