Meriam 70H_72H High Pressure Wet Tap Accutubes with Integral 3-Valve Head and Optional RTD User Manual

Page 12

12

4.3.10 For maximum number of remakes, mark the fitting and nut (scribe or ink)

before disassembly. Remake by tightening until marks line up again. A slight

torque rise will be felt indicating the ferrule is being re-sprung into sealing

position. Only after several remakes may it become necessary to advance the

nut slightly past original position. This advance need only be 10

° - 20° (less

than 1/3 of a hex flat).

4.3.11 The Accutube is now prepared for instrument connection and operation.

4.4

INSERTION FLOW SENSORS, FLANGE MOUNT: SERIES 24D & 25D

4.4.1

Perform general preparation as listed in Sections 4.1.1 through 4.1.4. Note that

with this series, a weld coupling, not a threaded coupling is used for mounting.

In the case of Series 25D the opposite end support is still a threaded coupling.

4.4.2

Place the weld neck flange on top the welded coupling and verify that the

dimension A is as shown in Figure 4.2. This dimension establishes the position

of the sensing ports within the pipe and allows for thermal expansion of the

probe. The allowable tolerance is + 1/16”, -0”.

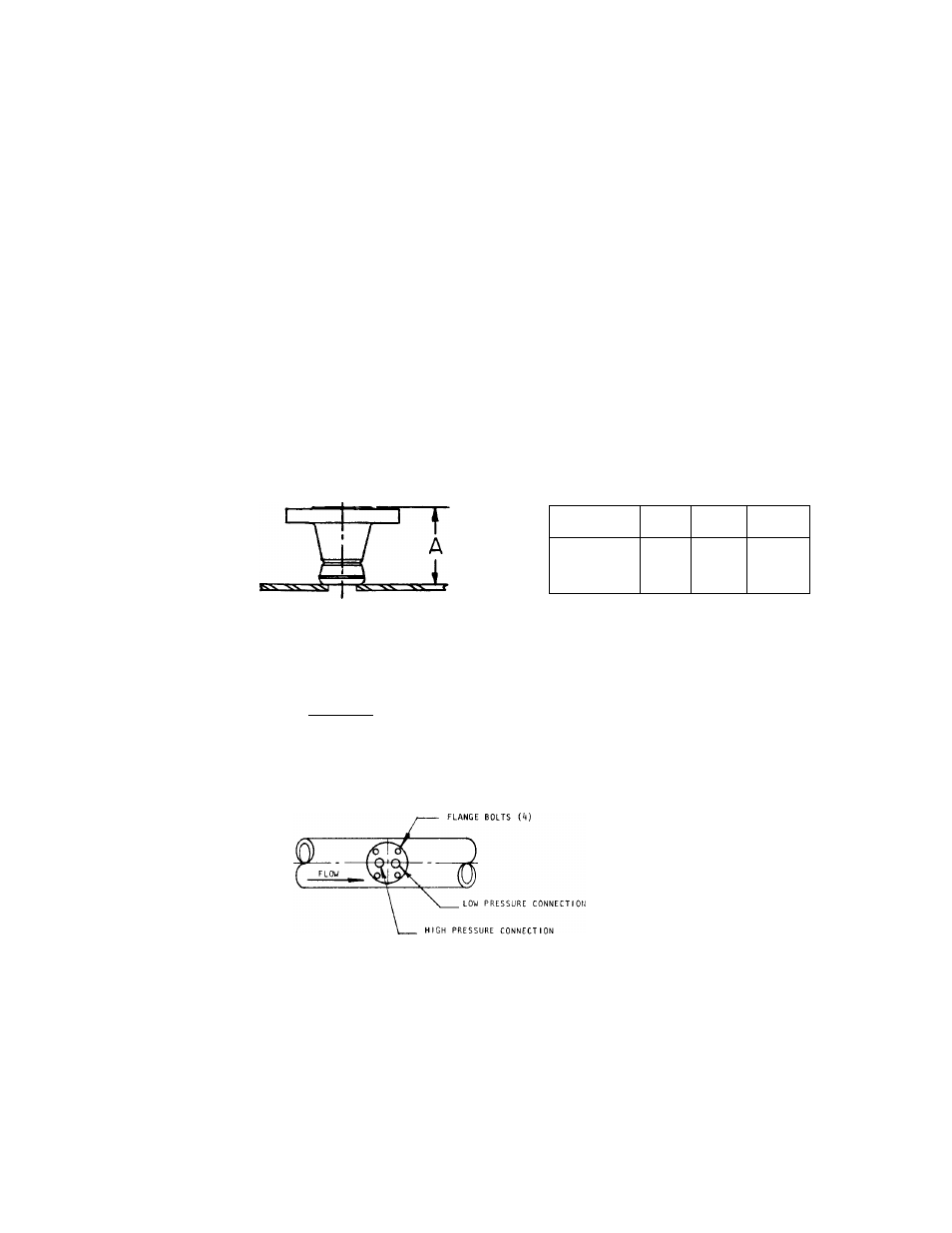

FIGURE 4.2 24D/25D MOUNTING HEIGHT FOR 150lb FLANGE

4.4.3

Tack weld the weld neck flange onto the Weld-O-Let so that the four holes on

the flange straddle the pipe centerline. An imaginary line drawn through any

two adjacent holes should run parallel to pipe centerline or perpendicular to it.

Refer to Figure 4.3.

FIGURE 4.3 24D/25D FLANGE ORIENTATION

Probe Dia.

1/2”

1”

2-3/8”

A

+ 1/16

- 0

3-1/2

3-1/2

4-3/8

- 40H to 43H Insertion Accutube with Integral 3-Valve Head 33T Low Pressure Accutube and Wet Tap Mounting Assemblies 37L High pressure Wet Tap Accutube 24D_25D Flange Mount Accutube 22L_23L High Pressure, Insertion Type Accutube 20T_21T Low Pressure, Insertion Type Accutube 10 A_11A Inline Type Accutube