Discontinued – Max Machinery 272-5X8 BIDIRECTIONAL TRANSMITTER (210_240 SERIES FLOW METERS) User Manual

Page 12

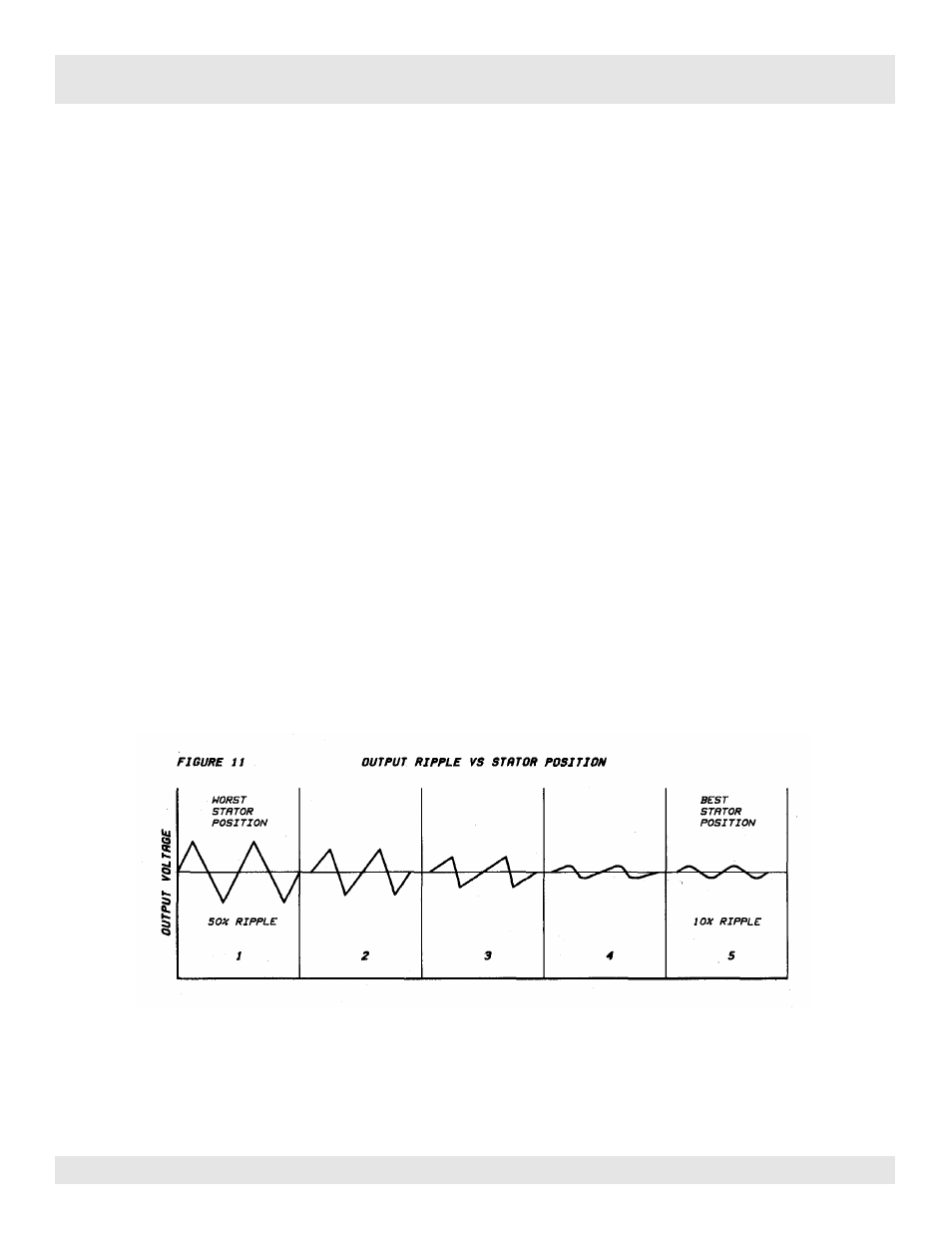

If this is not done, the electrical output of a meter and its transmitter will have as much as

50% ripple superimposed on the DC component of the output signal. The frequency of this

ripple will be four times the RPM of the meter. Such a situation will require more damping

than otherwise and will result in a slower responding system.

Ripple Adjustment Sensitivity: Increases and decreases the sensitivity of the ripple detection

circuit.

Ripple Indication : LED

Stator Adjustment Screw: Rotates the transmitter pickup coil.

The flow meter must have a flow through it for this adjustment to be useful. It is advisable to

adjust the ripple at the lower end of the flow range; although if the flow rate is less than 2% of

the flow meter ’s full scale capability you may have problems with this procedure. An oscillo-

scope attached to the output signal of the Model 272 can also be used.

Increase the Sensitivity Adjustment (cw) just until the Ripple LED next to it starts to turn on.

Then turn the Stator Adjustment Screw in a direction that decreases the brightness or turns off

the Ripple LED. Once again increase the Sensitivity potentiometer until the LED just comes on

and again turn the stator adjustment in a direction that minimizes the LED. Repeat this process

until any further change in the position of the stator screw causes the LED brightness to

increase rather than decrease.

The figure 11 shows the effect of the stator position on output ripple. There are four best and

four worst positions for the stator per revolution. This means that it will take a maximum of

45° on the Stator Adjustment Screw to find the best location.

Page 12

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

USER OPTIONS AND ADJUSTMENTS

Discontinued