Mach III Clutch T6H1G-STL, T6H1H-STL, T6H2H-STL User Manual

Page 4

7/9/2013

TORQLIM_FLEXCOUPL_MANUAL

Page 4 of 5

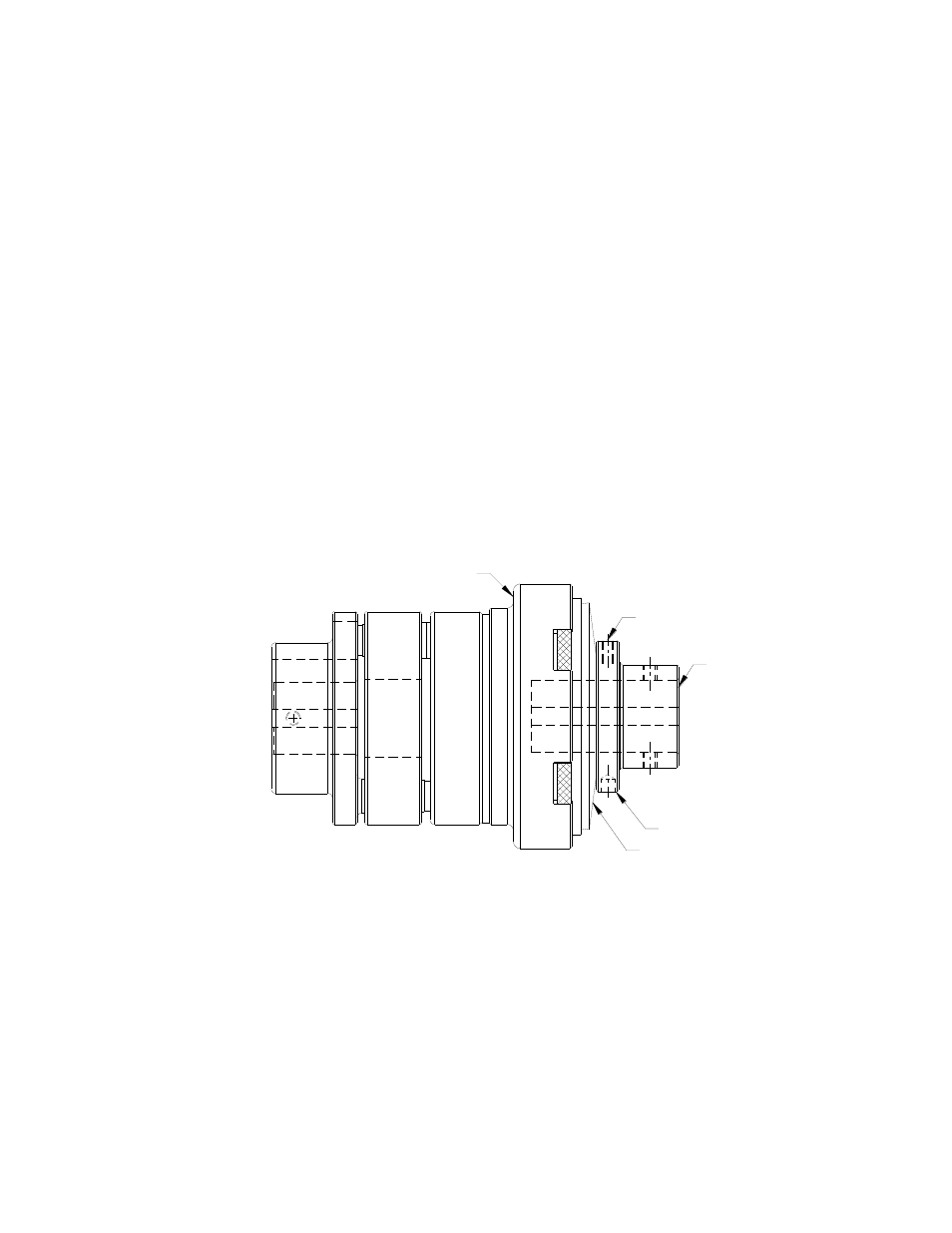

A

B

C

D

E

B. DRIVE SURFACE INSPECTION & FRICTION DISC REPLACEMENT

Inspect the surface of the steel or iron dive discs. This surface must be free from grooves, burrs

and foreign materials in order for the clutch to operate properly. If damage is pronounced,

please contact Mach III Clutch or your distributor about replacing the drive discs. In addition,

clutch should be inspected for discoloration (turning blue). If discoloration is present, the unit is

being operated beyond its capacity and Mach III Clutch should be contacted for assistance.

C. INSPECTION OF BEARINGS

Check bearings for external damage (missing seals, etc.). Make sure the bearings rotate freely

and smoothly by hand. If bearing replacement is necessary, consult Mach III or your distributor

for the bearing sizes and replacement procedures.

D. REASSEMBLY

Place drive discs, friction discs and spring over drive hub in their proper order making sure they

slide freely on the hub and in the slots. Replace adjustment nut with the shoulder fitting into the

bore of the spring. Adjust torque and tighten set screw.

See “torque Limiter Installation” portion of these instructions for the proper procedure for

reinstalling the clutch.

VII.

Torque Setting Instructions

A. Product Numbers: T3H2H-STL, T4H2H-STL, T5H2H-STL and non-catalog

variations of this torque limiter design.

(1) Make sure the nylon-tipped set screw (REF. C) in the outside diameter of the adjustment nut

(REF. A) is loose.

(2) Make sure the adjustment nut (REF. A) is snug against the disc spring (REF. B).

(3) Using a spanner wrench, tighten the adjustment nut (REF. A) against the disc spring

(4) Check torque value after each 1/4-turn increment of the adjustment nut (REF. A) while holding

adapter/sleeve (REF. D) stationary and turning drive hub (REF. E) with a torque wrench.

(5) Tighten the nylon-tipped set screw (REF. C) in the outside diameter of the adjustment nut

(REF. A).