Main terminal, Sw 2 - left 4 switches, Sw 1 – Controlled Products Systems Group 9210-081 User Manual

Page 2: Sw 2, Sw 1 - right 8 switches, Switch function setting description

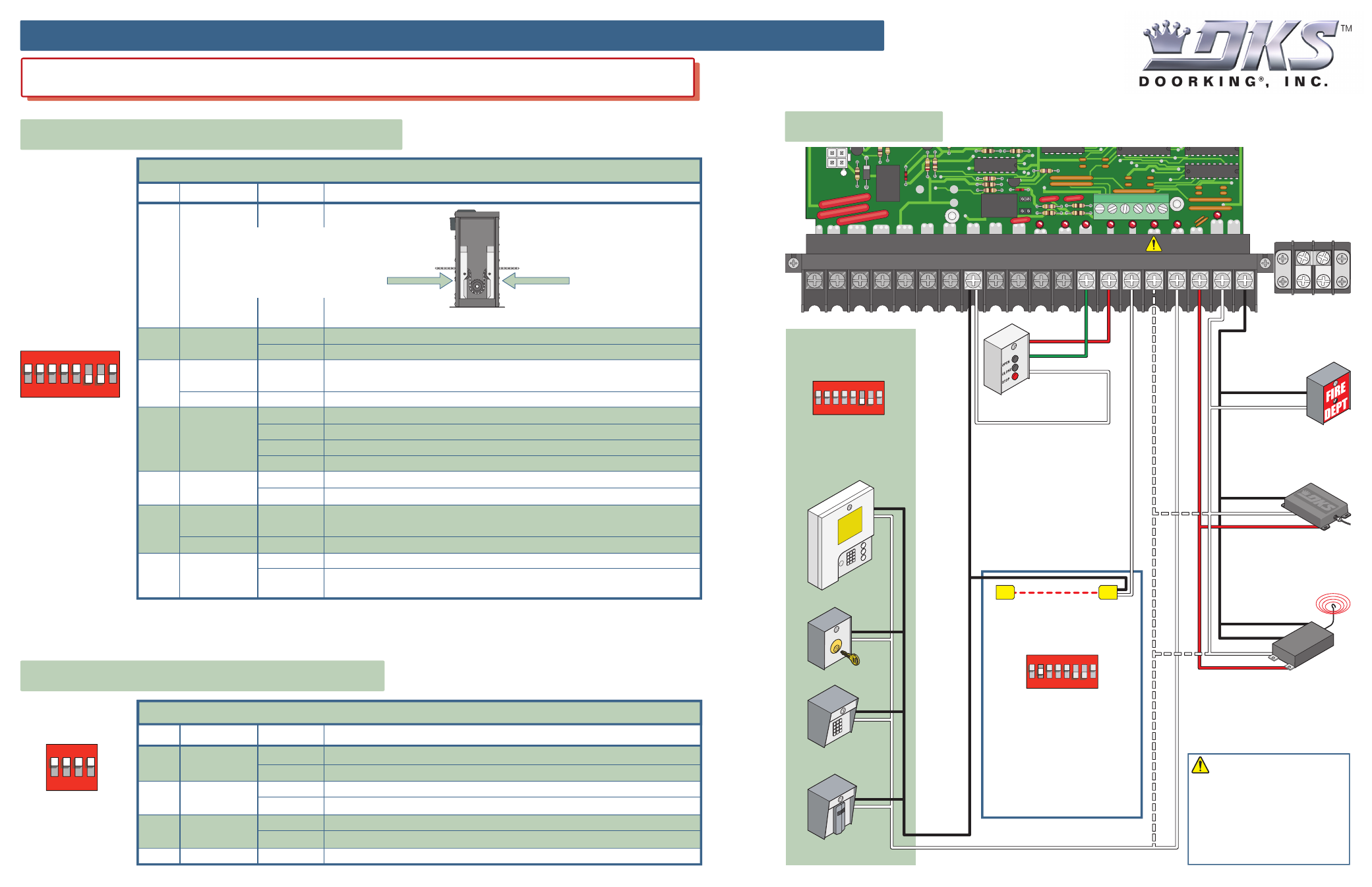

SW 1 DIP-Switches (Right Hand Side)

SW 2 DIP-Switches (Left Hand Side)

NC

NO

P7

20 19 18 17 16 15 14

13

12 11 10 9

8 7 6 5 4 3 2 1

Red Full Open

Green Close

White Com

Key Switch

Stand-Alone

Keypad

Stand-Alone

Card Reader

Telephone Entry

3-Button Control Station

DoorKing ONLY

Functions ONLY during gate closing cycle.

Note: All stand-alone and

telephone entry devices must

use a separate power source.

Important:

Controls must be

far enough from the gate so

that the user is prevented

from coming in contact with

the gate while operating the

controls. Outdoor or easily

accessible controls should

have a security feature to

prevent unauthorized use.

“Optional” REVERSE GATE

for Closing Direction

Photo Sensors

#1-Com

#1-Com

#5 - Partial Open (See manual)

#4 - Full Open

Com

To #4 or #5

#2 or #5-Relay

250 mamp. max.

#3-24 volt

#1-Relay Com

#2 or #5-Relay

#1-24 Volt Power Com

#3-24 Volt Power

4-Wire Radio Receiver

#2-Fully opens gate.

3-Wire Radio Receiver

Safety Opening Device

SW 1, switch 7: After photo sensor beam

gets obstructed:

OFF Setting - REVERSES GATE.

ON Setting - Stops gate then continues

closing when gate is clear (Same function

as UL 325 terminal #2).

Note: The ON setting is used to help

prevent tailgating but the photo sensor

should be wired to the UL 325 terminal #2

when the “stop gate” function is desired,

see manual for more information.

#5 Terminal Note: Any opening

device connected to terminal #5 will

open the gate to the partial open

setting. Secondary entrapment

protection devices will also open the

gate to the partial open setting. If the

Inherent Reverse Sensor gets

activated during the close cycle, it

will always fully open the gate.

1

ON

23

45

6

7

8

SW 1 is Upside-Down on Board

1

ON

2

3

45

67

8

SW 1 is Upside-Down on Board

Auxiliary Common

Terminal

Connect any common

wire to these 2 terminals.

SW 1, Switch 3 MUST be ON

except for dual operators or

exit loop partial open

applications.

Main Terminal

1

ON

23

45

67

8

1

ON

23

4

Switch Function

Setting

Description

SW 2 - Left 4 Switches

2

Spare

4

1

Self-Test

Gate Opens

Uphill

3

Gate Opens

Downhill

OFF

ON

Normal Setting. Normal gate operation.

Self-test mode. Operator MUST be disconnected from gate to run self-test.

OFF

ON

Normal Setting. Normal gate operation.

MUST be ON if gate opens UPHILL.

OFF

ON

Normal Setting. Normal gate operation.

MUST be ON if gate opens DOWNHILL.

OFF Leave in the OFF position.

SW 1

Upside-Down on Circuit Board.

SW 2

Upside-Down on Circuit Board.

Exit Loop Port

Output

Full Open Input

Factory Set Configuration

Warn Before

Operate

The output wired to terminal #4 becomes the output from the loop detector

installed in the EXIT loop port. Plug-in loop detector required for “OFF” function.

Normal Setting. Terminal #4 is a normal full open input for a single gate operator.

Reverses Gate

Stops Gate

Switch Function

Setting

Description

SW 1 - Right 8 Switches

OFF

ON

4-OFF

4-OFF

4-ON

4-ON

5-OFF

5-ON

5-OFF

5-ON

Auto-Close

Timer

Relay Activation

and

LED Indicator

Light Activation

2

1

3

4 and 5

7

8

OFF

ON

OFF

ON

Normal Setting. No sound.

Internal alarm will sound before gate starts and throughout gate’s cycle.

Auto-close timer is OFF. Manual input required to close gate.

Auto-close timer is ON. Adjustable from 1-23 seconds to close gate.

6

Relay activates and LED is ON when the gate is fully open.

Relay activates and LED is ON when the gate is not closed.

Relay activates and LED is ON when the gate is opening and open.

Relay activates and LED is ON when the gate is opening and closing.

Changes the direction

the operator will

open/close the gate.

Opening direction

using ON setting.

Opening direction

using OFF setting.

OFF

ON

Normal Setting. Timer will function normally.

Opening gate will stop and begin to close as soon as all reversing inputs (Reverse

loops, photo sensors) are cleared regardless of the distance the gate has opened.

OFF

ON

Normal Setting. Input to terminal #6 and/or reverse loops will REVERSE gate

during CLOSE cycle.

Input to terminal #6 and/or reverse loops will STOP gate during CLOSE cycle.

Quick-Close

Timer Override

Jumper Wire

Needed

See Manual

Note: After a DIP-switch setting is changed, power must be turned

OFF and then turned back on for the new setting to take affect.

QUICKSTART “BASIC” GUIDELINES FOR MODEL 9200 - DIP-SWITCH AND WIRING REFERENCE

120 Glasgow Avenue

Inglewood, California 90301

U.S.A.

Model 9200 is intended for installation only on sliding gates used for vehicles.

Pedestrians must be supplied with a separate access opening. For safety and installation instructions, please refer to the Installation/Owner’s manual.