Start-up – Controlled Products Systems Group 10978021 User Manual

Page 4

9

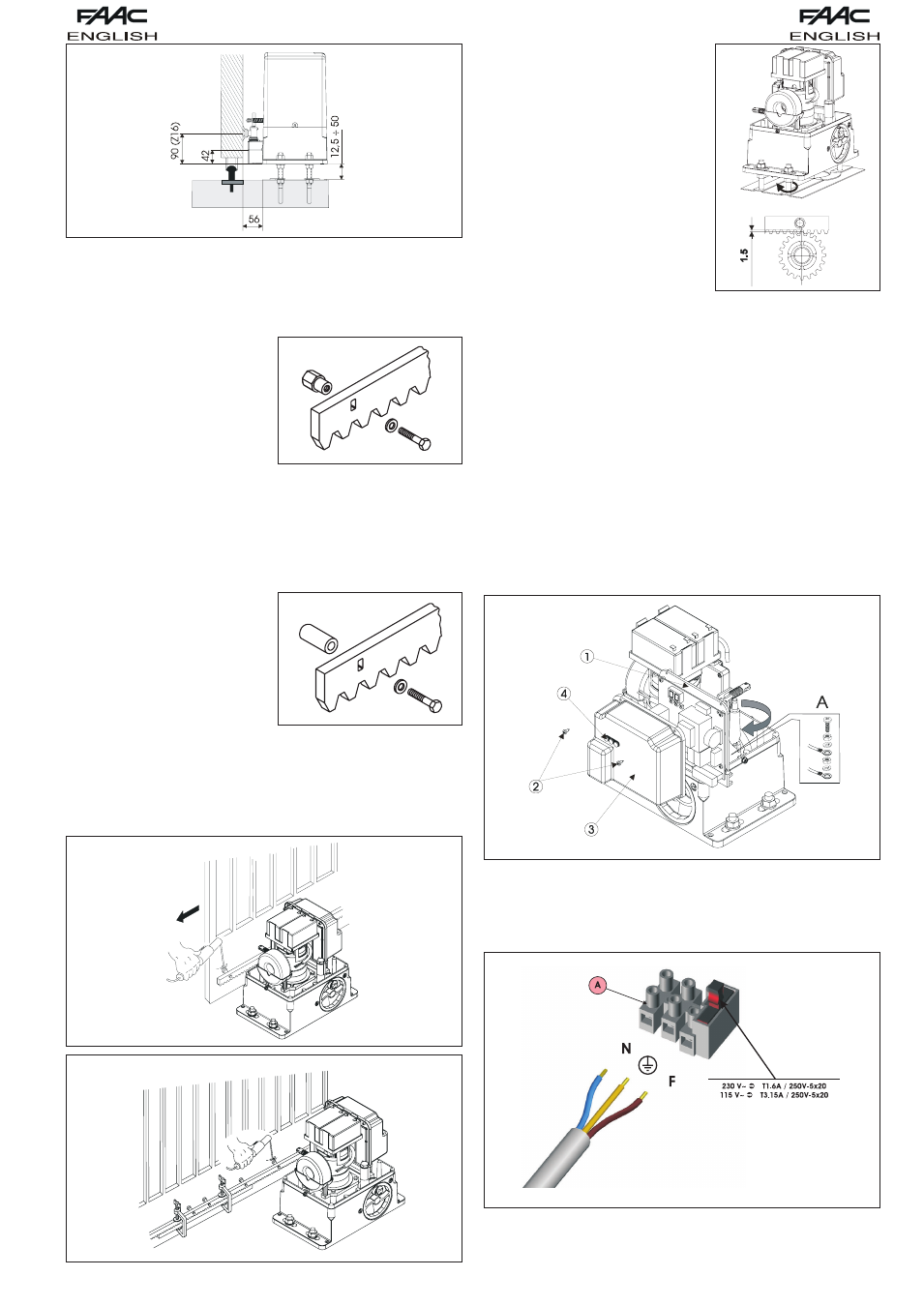

Fig.10

Fig.11

Fig.13

Fig.14

Fig.16

Fig.15

Fig.12

4- Secure the gearmotor to the plate, tightening the nuts.

5- Prepare the operator for manual operation as described in paragraph 8.

5.4. Assembling the rack

5.4.1. Steel rack to weld (Fig. 11)

1) Fit the three threaded pawls on the rack element, positioning them at the

bottom of the slot. In this way, the slot play will enable any future adjustments

to be made.

2) Manually take the leaf into its closing

position.

3) Lay the first section of rack level on the

pinion and weld the threaded pawl on

the gate as shown in Fig. 13.

4) Move the gate manually, checking if

the rack is resting on the pinion, and

weld the second and third pawl.

5) Position another rack element end to

end with the previous one, using a

section of rack (as shown in Fig. 14) to

synchronise the teeth of the two elements.

6) Move the gate manually and weld the three threaded pawls, thus

proceeding until the gate is fully covered.

5.4.2. Steel rack to screw (Fig. 12)

1) Manually take the leaf into its closing position.

2) Lay the first section of rack level on the pinion and place the spacer between

the rack and the gate, positioning it at the bottom of the slot.

3) Mark the drilling point on the gate. Drill a Ø 6,5 mm hole and thread with an

M8 male tap. Screw the bolt.

4) Move the gate manually, checking if

the rack is resting on the pinion, and

repeat the operations at point 3.

5) Position another rack element end to

end with the previous one, using a

section of rack (as shown in figure 14) to

synchronise the teeth of the two

elements.

6) Move the gate manually and carry

out the securing operations as for the

first element, thus proceeding until the

gate is fully covered.

Notes on rack installation

• Make sure that, during the gate travel, all

the rack elements do not exit the pinion.

• Do not, on any account, weld the rack

elements either to the spacers or to each

other.

• When the rack has been installed, to ensure

it meshes correctly with the pinion, it is

advisable to lower the gearmotor position

by about 1.5 mm (Fig.15).

• Manually check if the gate correctly

reaches the mechanical limit stops

maintaining the pinion and rack coupled

and make sure there is no friction during

gate travel.

• Do not use grease or other lubricants

between rack and pinion.

6. START-UP

6.1. Control board connection

Before attempting any work on the board (connections, programming,

maintenance), always turn off power.

Follow points 10, 11, 12, 13 and14 of the GENERAL SAFETY OBLIGATIONS.

Following the instructions in Fig. 3, route the cables through the raceways and

make the necessary electric connections to the selected accessories.

Always separate power cables from control and safety cables (push-button,

receiver, photocells, etc.). To avoid any electric noise whatever, use separate

sheaths.

6.1.1. Earthing

Connect the earth cables as shown in Fig.16 ref.A.

6.1.2. Electronic control unit

In the gearmotors, the electronic control unit is fitted to an adjustable support

(Fig. 16 ref. 1) with transparent lid (Fig. 16 ref. 3).

The board programming push buttons (Fig. 16 ref. 4) have been located on the

lid. This allow the board to be programmed without removing the lid.

For correct connection of the control unit, follow indications the specific instructions:

Values are expressed in mm

V

a

lues are expr

essed in

mm

6.1.3. Connection of power cable

The 740-24V gearmotor houses a screw terminal with fuse-holder (Fig 17 Ref. A)

connected to the primary circuit of the toroidal transformer. The mains power

cable 230 / 115 V ~ must be connected to this terminal, respecting what was specified

in Fig. 17. If you have to replace the fuse, use a fuse type T1.6A/250V - 5x20 for a

230V power supply and type T3.15A/250V - 5x20 for a 115V power supply.

Fig.17