Maintenance, Maintenance schedule – Ariens SNO-THRO 924333 - 1024 User Manual

Page 15

GB - 15

Ariens Dealers will provide any service or adjustments

which may be required to keep your unit operating at

peak efficiency. Should engine service be required,

contact an Ariens dealer or an authorized engine

manufacturer's service center.

SERVICE POSITION

Place unit in service position when required. Place unit

on a flat level surface. Tip unit forward onto front of

Impeller housing for service. Assure unit is secure and

will not tip over. Strap and clamp onto bench if needed.

MAINTENANCE SCHEDULE

The chart below shows the recommended

maintenance schedule that should be performed on a

regular basis. More frequent service may be required

due to working conditions (heavy loads, high ambient

temperatures, dusty conditions, or airborne debris).

*

First Maintenance Only

CHECK FASTENERS

Make sure all hardware is tightened properly.

CHECK ENGINE OIL

The engine crankcase oil should be checked every 5

hours of operation. Oil level MUST be maintained in

safe operating range on dipstick at all times or engine

damage will result (See Engine Manual).

Park unit on a level surface. Refer to Engine Manual for

detailed instructions.

CHANGE ENGINE OIL

Change oil after first 5 hours of operation, thereafter

change oil every 25 hours (more often if required).

Refer to Engine Manual for detailed instructions.

Run engine just prior to changing oil. Warm oil will flow

more freely and carry away more contamination.

CHECK AUGER GEARCASE

IMPORTANT: Proper oil level must be maintained.

Gear cases are filled to the correct level at the factory.

Unless there is evidence of leakage, no additional

lubricant should be required. Check for evidence of

leakage every 25 hours of operation.

To ensure adequate lubricant level:

1. Remove filler plug (Figure 8). Lubricant must be

at least up to bottom of lubricant filler hole with

unit resting on a level-surface.

2. Add lubricant if required. Allow oil to drain to level

of plug and replace plug.

IMPORTANT: Use only Ariens special gear lubricant

L-2 (Part Number 00008000).

CHECK TIRE PRESSURE

Maintain the unit tire pressure at a maximum 14 PSI

(97 kPa).

MAINTENANCE

WARNING: AVOID INJURY. Read and

understand Maintenance and Service and

Battery Safety Rules in Safety section before

attempting any maintenance.

WARNING: Before tipping unit up onto

housing, remove fuel so no spills will occur

and remove battery (if equipped). Ensure unit

is secure and will not tip over during

maintenance.

MAINTENANCE SCHEDULE

Service Performed

Daily

Every

5 hrs.

Every

25 hrs.

Every

100 hrs.

Check Fasteners

•

Check Engine Oil

•

Change Engine Oil

*

•

Check Auger

Gearcase

•

Check Tire Pressure

•

General Lubrication

•

Battery Maintenance

•

Clean Engine

•

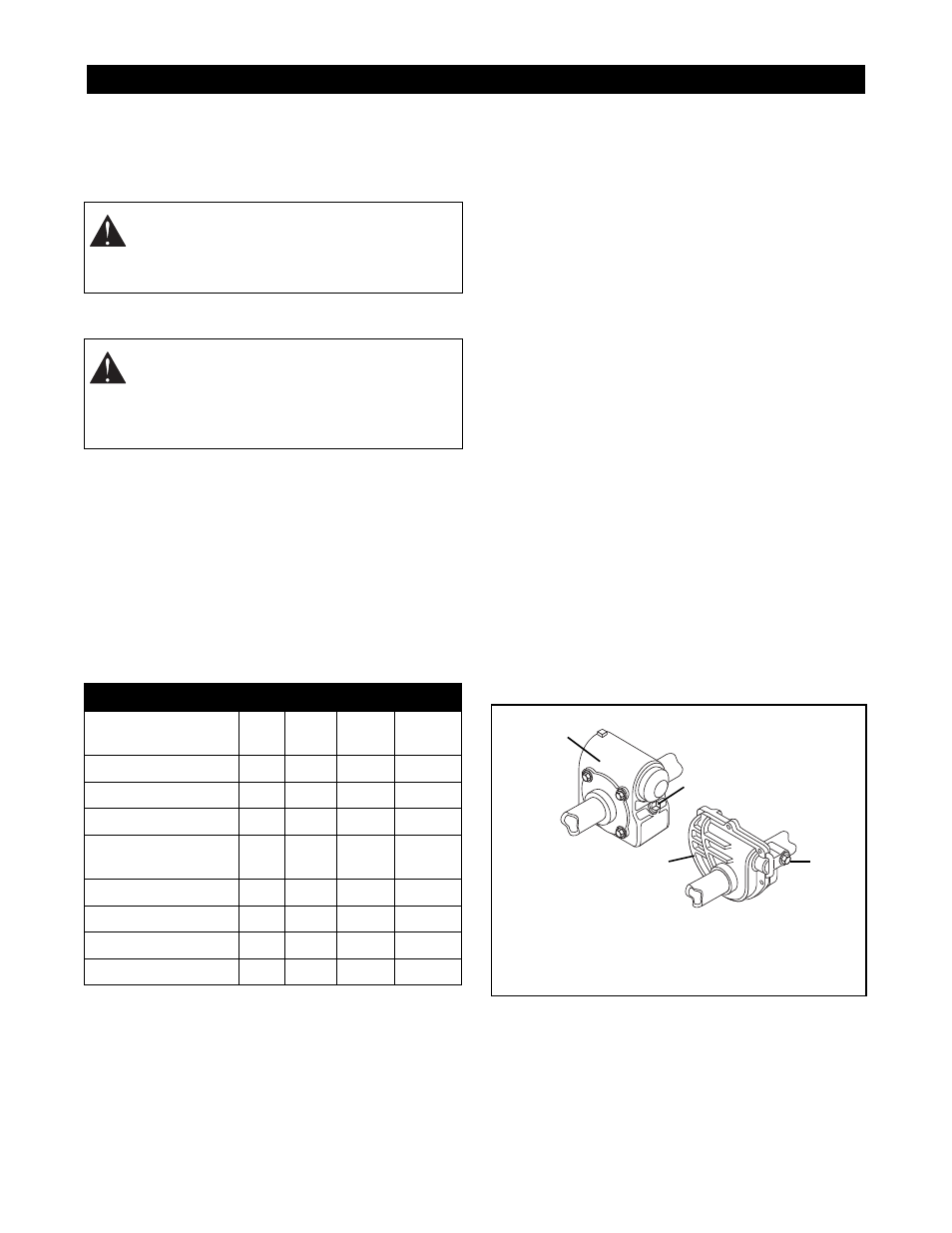

1. Auger Gearcase - Cast Iron

2. Oil Fill and Drain Plug

3. Auger Gearcase - Aluminum

1

2

3

2

Figure 8

OS0620