Codelocks CL525 Mortice Lock with Double Cylinder User Manual

Page 6

STEP 1

Lightly mark a height line on

the edge and both faces of

the door, and the door jamb,

to indicate the top of the lock

when fitted. Mark a line down

the centre of the door edge,

extending above the height line

and 300mm below it.

STEP 2

Hold the template against the

edge of the door with the top

in line with the height line, and

with the arrows in line with the

‘Centre of Door Edge’ line.

Mark the positions of the

fixing screws, and the holes to

be drilled for the mortice.

STEP 3

Apply tape to the 16mm drill

bit at 90mm from the tip to

act as a depth guide when

drilling the mortice holes.

Ensure the drill is level and

parallel to the door face and

drill the holes as indicated

on the template. Remove the

remaining wood with a chisel

to leave a clean mortice hole

which accepts the lockcase

without forcing. With the lock

in the mortice make sure that

the forend is parallel with

the door edge and mark the

outline of the forend plate. Cut

the outline with a Stanley knife

to avoid splitting out when

chiselling. Chisel a rebate

sufficient to accept the forend

flush with the surface.

STEP 4

Fold the template accurately

along the dotted line and tape

it to the door face with the top

in line with the height line, and

the fold on the door edge. Mark

the centres of all the holes to

be drilled. Remove the template

and repeat the procedure on

the other face of the door.

STEP 5

Drill the holes from both

sides of the door to improve

accuracy and to avoid

splintering out the door face.

STEP 6

Install the lockcase in the

door.

STEP 7

Cut two of the black socket

head bolts to the required

length for your door.

Approximate overall length

should be door thickness plus

25mm to allow about 10mm

of threaded bolt to enter the

outside plate.

STEP 8

Take the BLUE or RED tipped

spindle and fit to the

code

side according to the hand of

your door (see diagram).

Fit the butterfly spindle to the

inside,

non-code side.

STEP 9

Check that the lever handles

are correctly fitted for the hand

of door. To change the hand of

a lever handle, loosen the grub

screw with the small Allen key,

reverse the lever handle and

fully tighten the grub screw.

STEP 10

Apply the front and back

plates, with the neoprene

seals in position, against the

door, over the protruding ends

of the spindle.

STEP 11

Fix the two plates together

using the socket head bolts,

starting with the top fixing.

Ensure that the two plates

are truly vertical and then

tighten the bolts using the ‘T’

shaped Allen key. Do not use

excessive force.

STEP 12

Before closing the door,

enter the code and check that

the latchbolt will retract when

the lever handle is depressed.

Now check the operation of

the inside lever handle. If there

is any binding of the handles

or the latch then loosen

the bolts and reposition the

plates slightly until the correct

position is found, and then

re-tighten the bolts.

STEP 13

Fit the double Euro-profile

cylinder and secure it with

the long screw through the

faceplate. Fit the cylinder

escutcheons.

STEP 14

Check that the deadbolt will

project and retract by key, and

that the key will also retract

the latchbolt.

Check that the inside lever

handle WILL retract the

deadbolt simultaneously with

the latchbolt.

Check that the outside lever

handle WILL NOT retract the

deadbolt.

STEP 15

Mark a vertical line on the door

jamb half the door thickness

away from the door stop. This

gives the centre line of the strike

plate. Align the Strike Plate

Template with the height line,

with the arrow heads aligned

with the centre line. Mark the

fixing holes, and draw around

the apertures for the latchbolt

and the deadbolt. Chisel out the

latch aperture to 12mm deep,

and the deadbolt aperture to

22mm deep.

Fix the strike plate with the top

screw only and gently close the

door. Ensure that the latchbolt

enters its aperture easily and

holds the door without too

much ‘play’. When satisfied,

draw around the final position

of the strike plate, remove it,

and cut a rebate to allow it to fit

flush to the surface. Re-fix the

strike with both screws.

Door hung on RIGHT

viewed from the code side

Door hung on LEFT

viewed from the code side

RED

BLUE

Door hung on RIGHT

viewed from the code side

Door hung on LEFT

viewed from the code side

Door hung on RIGHT

viewed from the code side

Door hung on LEFT

viewed from the code side

RED

BLUE

Door hung on RIGHT

viewed from the code side

Door hung on LEFT

viewed from the code side

BLUE

RED

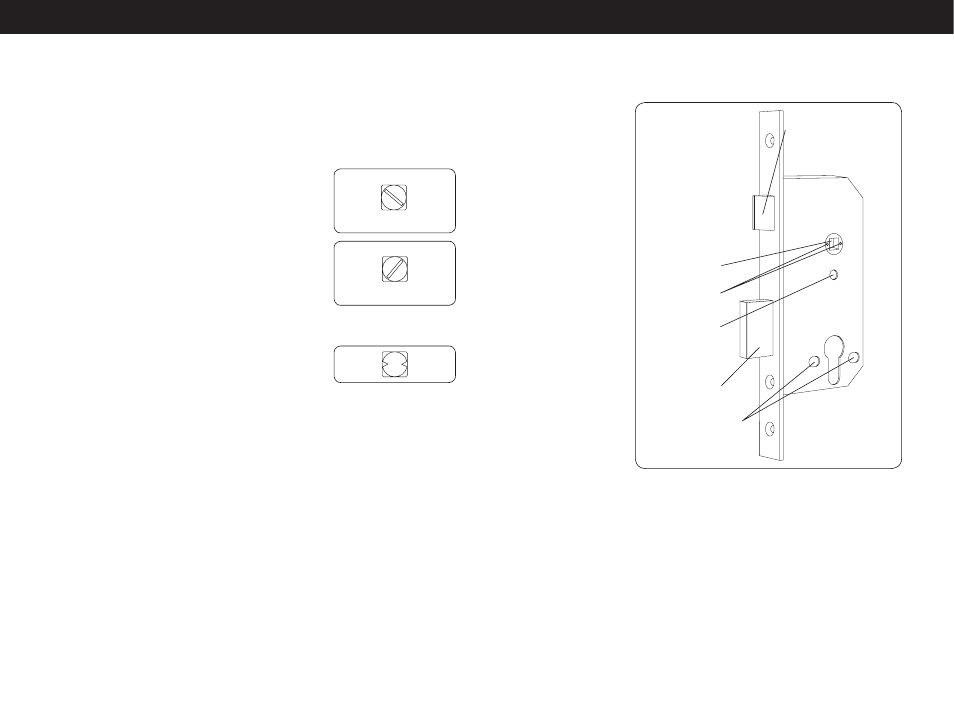

22mm bolt throw

Hole for bolt

through fixing

Grub screws

Split follower

Bolt through fixings

for escutcheons

Easy to reverse

key action latchbolt

FIGURE 2

520/525 lockcase

- CL520 Mortice Lock with Double Cylinder CL515 Tubular Mortice Latch Back to Back CL510 Tubular Mortice Latch Back to Back CL515 Heavy Duty Tubular Mortice Latch CL510 Heavy Duty Tubular Mortice Latch CL505 Panic Access Kit CL500 Panic Access Kit CL505 Front and Back Plates, Back to Back CL500 Front and Back Plates, Back to Back CL505 Front and Back Plates CL500 Front and Back Plates