Codelocks CL525 Mortice Lock with Double Cylinder User Manual

Page 4

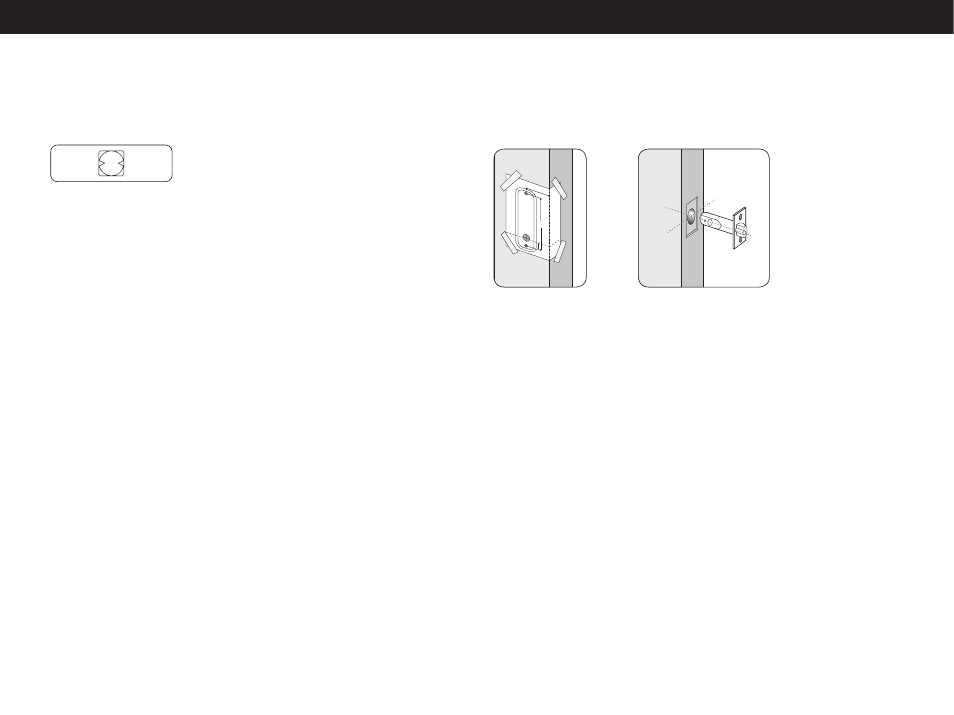

STEP 1

Lightly mark a height line on

the edge and both faces of the

door, and on the door jamb,

to indicate the top of the lock

when fitted.

Crease the template along the

dotted line, and tape it to the

door with the top in line with

the height line.

Mark the 2x 12mm and the

1x 30mm holes. Mark the

centre of the door edge on the

Centre Line of Latch. Remove

the template and apply it to

the other side of the door,

aligning it accurately with the

first Centre Line of Latch mark.

Mark the 4 holes again.

STEP 2

Keeping the drill level and

square to the door, drill a

25mm hole to accept the latch.

STEP 3

Keeping the drill level and

square to the door, drill the

12mm and 30mm holes from

both sides of the door to

increase accuracy and to avoid

splintering out the door face.

STEP 4

Put the latch into the hole

and, holding it square to the

door edge, draw around the

faceplate. Remove the latch

and score the outline with a

Stanley knife to avoid splitting

when chiselling. Chisel a rebate

to allow the latch to fit flush to

the surface.

The model 510/515 has a tubular, deadlocking, mortice latch and may be used

as a new installation on a door, or where an existing latch is to be replaced.

MODEL 510/515 INSTALLATION INSTRUCTIONS

STEP 2 (continued)

Fit the butterfly spindle to the

inside,

non-code side.

STEP 3

Check that the lever handles

are correctly fitted for the

hand of door. To change the

hand of a lever handle, loosen

the grub screw with the small

Allen key, reverse the lever

handle and fully tighten the

grub screw.

STEP 4

Take the adaptor kit, item 13

on the contents page. Cut

the two M5 countersunk head

bolts to length to suit the door

thickness; i.e. door thickness

plus a maximum of 10mm

(no more than 5mm should

enter the front plate). Hold

the front plate, with the three

hole neoprene seal, against

the door over the protruding

spindle. From the other side

of the door, fix the adaptor

plate to the front plate using

the two M5 countersunk

bolts. Before tightening up

the fixings, make sure that

the spindle hole is centrally

positioned over the follower.

Do not use excessive force.

STEP 5

Cut one of the long black

socket head screws to the

required length for your door.

Approximate overall length

should be door thickness

plus 25mm, to allow about

10mm of threaded bolt to

enter the front plate.

Place the neoprene gasket

over the adaptor plate.

Use the screw with the

‘T’ shaped Allen key, to fix

the back plate to the front

plate through the TOP hole.

Using the 20mm socket

head screw fix the back plate

through the BOTTOM hole

to the adaptor plate. Do not

use excessive force.

STEP 6

Before closing the door,

enter the code and check

that the latchbolt retracts

when the lever handle is

depressed. Now check the

operation of the inside lever

handle. If there is any binding

of the handles or latch then

loosen the top and bottom

bolts and reposition the

plates slightly until the correct

position is found, and then re-

tighten the bolts.

STEP 5

Fix the latch with the wood

screws, with the bevel towards

the door frame.

STEP 6

Fitting the strike plate.

NB: The plunger beside the

latchbolt deadlocks it, to

protect against manipulation

or ‘shimming’. The strike plate

must be accurately installed so

that the plunger CANNOT enter

the aperture when the door is

closed, even if it is slammed shut.

Position the strike plate on the

door frame so that it lines up

with the flat of the latchbolt,

and NOT the plunger. Mark the

positions of the fixing screws,

and draw around the aperture

of the strike plate. Chisel out

the aperture 15mm deep to

receive the latchbolt. Fix the

strike plate to the surface of

the frame using only the top

fixing screw. Gently close

the door and check that the

latchbolt enters the aperture

easily, and is held without too

much ‘play’. When satisfied,

draw around the outline of

the strike plate, remove it and

cut a rebate to enable the

faceplate to lie flush with the

surface. Re-fix the strike plate

using both screws.

NB Ensure enough room

for the latch support post

NB Space required above

latch body for cam to rotate

- CL520 Mortice Lock with Double Cylinder CL515 Tubular Mortice Latch Back to Back CL510 Tubular Mortice Latch Back to Back CL515 Heavy Duty Tubular Mortice Latch CL510 Heavy Duty Tubular Mortice Latch CL505 Panic Access Kit CL500 Panic Access Kit CL505 Front and Back Plates, Back to Back CL500 Front and Back Plates, Back to Back CL505 Front and Back Plates CL500 Front and Back Plates