8 adjustment tools, Djustment, Ools – Cleveland Motion Controls Classic Series DIN Rail Amplifier with Isolated Output MWI-13467 REV CA User Manual

Page 26

C

LASSIC

S

ERIES

A

MPLIFIER W

/

I

SOLATED

O

UTPUTS

MAN-13467

REV

CA

Page 26 of 30

3.8 A

DJUSTMENT

T

OOLS

Using the correct tools simplifies making the necessary adjustments during the setup procedure. Keep the

following points in mind:

• The Classic Series DIN Rail amplifier utilizes two different potentiometer

styles. The Gain and Zero adjustments located on the front of the amplifier

are more likely to be adjusted over the life of the product. For that reason

they are physically larger and more robust. The industry standard “pot

tweaker” is an ideal tool. The adjustment tool should have dimension on

the order of 0.5mm (.020 inches) blade thickness and be 2.5 mm wide

(0.1inches).

• The adjustments that are usually made only once during initial setup are located

behind a snap on access cover. This less obvious location helps to discourage

alteration by unqualified persons. The infrequent adjustment of these

potentiometers has warranted the use of smaller surface mount technology devices

(SMT). A correspondingly narrower blade is needed (1.4 mm wide, 0.055”inches).

• When changing the internal jumper-switch settings, it is always advisable to change

the settings with the 24 VDC power removed. If this is not possible, it becomes

particularly important to use a non-conductive tool to alter switch positions. Be sure

that jumper-switch settings are fully positioned, to avoid accidentally putting it in

an “in-between” state.

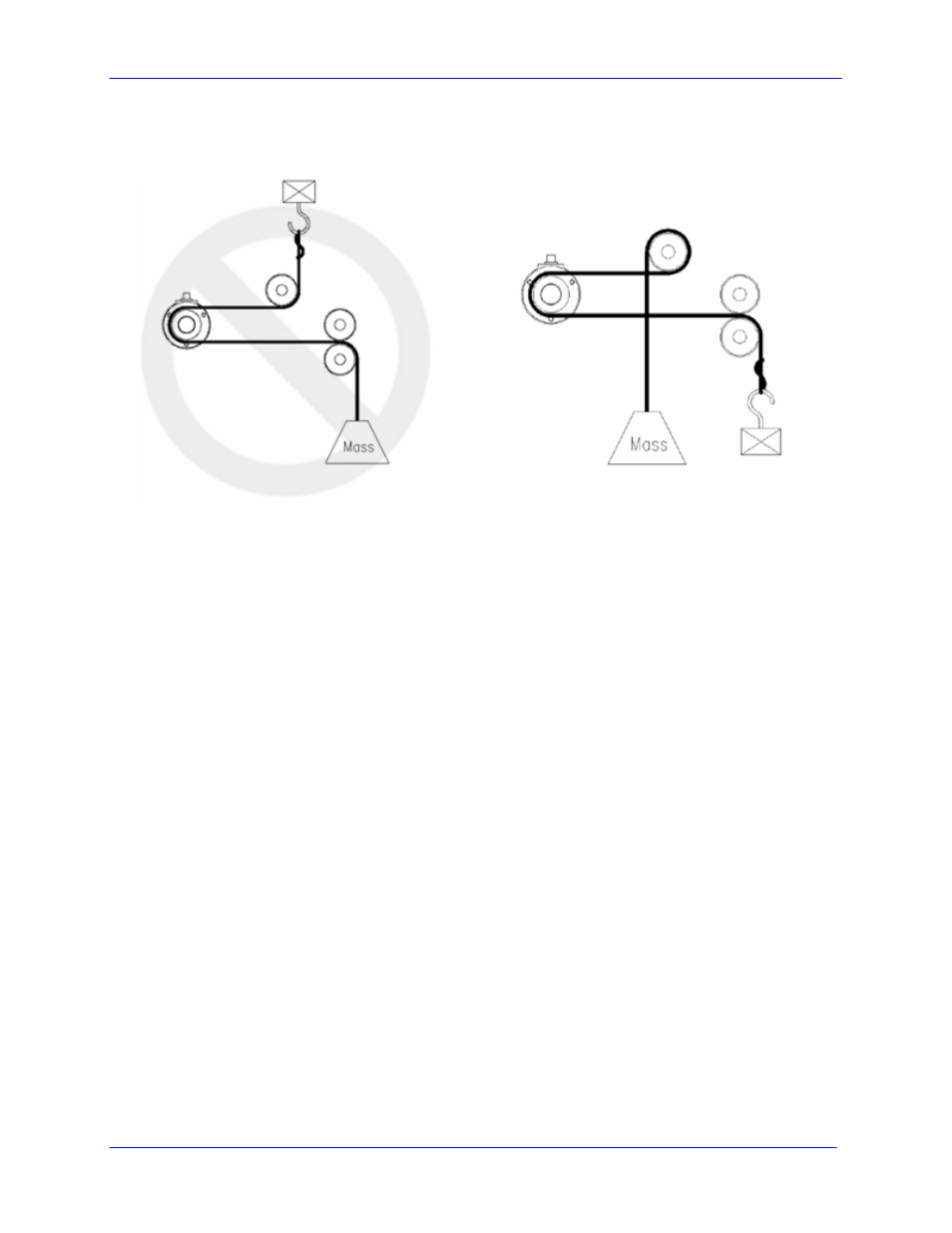

Examples of Force Loss due to Friction at Driven Roll

In this example, only a fraction of the test force is

transferred to the transducer due to drag from the

driven roll.

In this example, by rearranging the anchor point

and the force location as well as utilizing the idle

roll, the frictional losses are minimized.