Cleveland Motion Controls Classic CLT Cantilevered Transducer REV AA User Manual

Page 10

AO-70135

10 of 11

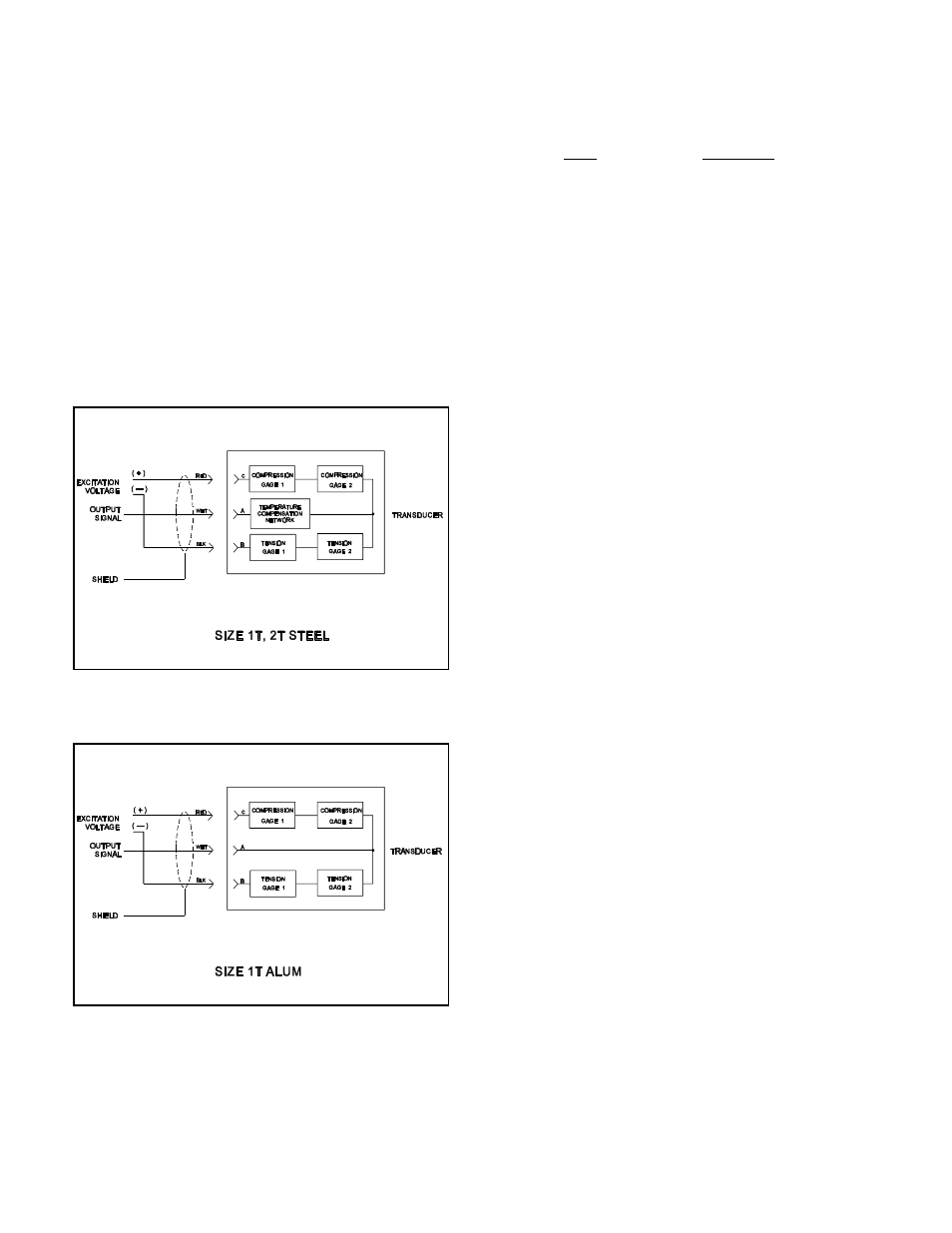

Figure 4

Figure 5

3.0 ELECTRICAL CONNECTIONS

Refer the the installation wiring diagram supplied with

the CLEVELAND-KIDDER tension indicator or

controller for making the transducer connections. Make

certain that the cable does not interfere with the web

path and that it is away from gearing or other moving

parts.

The following wiring diagrams are for reference only.

Most of the CLEVELAND-KIDDER indicators and

controllers will accept a half bridge input as shown in

Figure 4 or in Figure 5. See the applicable installation

wiring diagrams for the tension indicator or controller.

3.1

MATING CONNECTORS FOR

TRANSDUCERS

USE

CMC P/N

Mating Straight Connector,

Boot and Clamp Kit

MO-09854

Mating 90 Angle Connector,

"

Boot and Clamp Kit

MO-09855

3.2

INTRINSICALLY SAFE TRANSDUCERS

These transducers are intrinsically safe only when they

are part of a complete intrinsically safe system using the

TIX-1 tension indicator or wired per CMC control

drawings.

For transducers utilizing a 5.6 VDC (±2.8 VDC)

excitation voltage refer to CMC Control Drawing A800-

42273. For transducers utilizing a +5VDC excitation

voltage refer to CMC Control Drawing A800-42281.

Barrier block assemblies and/or the individual barrier

blocks may be purchased from CMC. Please contact

CMC for part numbers and pricing.

4.0 TEMPERATURE COMPENSATION

The size 1T and 2T steel transducers are supplied with

a temperature compensation network which is in series

with the output signal lead. The compensation circuit is

designed to be used with a tension amplifier which has

an input impedance of 5K Ohms. If other than the input

impedances given above are used, drift will occur in the

tension amplifier output when the transducer

temperature changes. Size 1T aluminum transducers use

a beam material that does not require temperature

compensation.

5.0 TROUBLESHOOTING

5.1

LOW OUTPUT SIGNAL

The transducer may have too large a maximum working

force for the application. Replace with a lower

maximum working force transducer or increase the web

wrap angle.