General description, Specifications, Pecifications – Cleveland Motion Controls ULTRA SERIES SLIM CELL TRANSDUCER REV AA User Manual

Page 7

AO-70263

R

EV

AA

U

LTRA

S

ERIES

S

LIM

C

ELL

T

RANSDUCER

P

AGE

7

OF

18

2

GENERAL DESCRIPTION

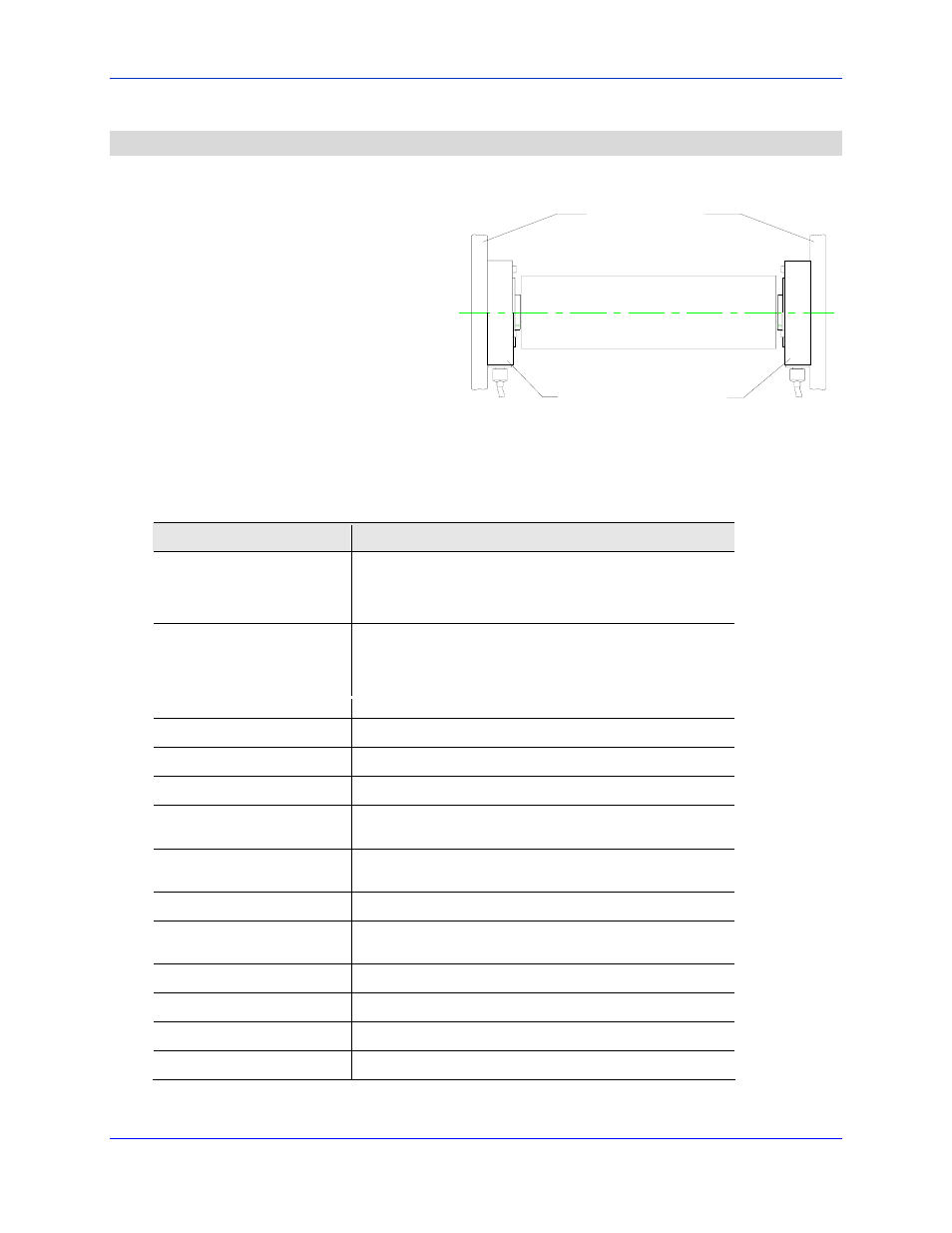

The Ultra Series Slim Cell Transducer utilizes a twin sensing beam. Conversion from mechanical strain to an

electrical signal is accomplished using

semiconductor-based, piezoresistive strain gage

elements. The Full Wheatstone Bridge configuration

provides an electrically balanced output yielding

twice the amount of signal swing as half-bridged

transducers operated at the same excitation voltage.

Integral span compensation is used to correct for

temperature induced gain changes.

MACHINE FRAME

SLIM CELL TRANSDUCER

Slim Cell Transducers can be used with either

rotating (live) shaft rolls (RS type) or, stationary

(dead) shaft rolls (SS type) that incorporate their

own low friction bearings. For more information on

transducer type selection refer to Section 1.1.

Figure 1- Slim Cell Transducer Incorporating Shaft

Bearing Function

2.1 S

PECIFICATIONS

Item:

Specification:

Transducer Weight

Slim Cell 1

Slim Cell 2

2.8 lbs.

1.3 kg

6.6 lb.

3.0 kg.

Weight + Bracket

Slim Cell 1

Slim Cell 2

5.5 lbs.

2.5 kg.

11.6 lb.

5.3 kg.

Material

Body and Side Plates – Stainless Steel 410

Bridge Resistance

135-147 Ohms @ 20

o

C

Gage Type

Semi-conductor strain gage, gage factor equals 95 (nominal)

Connector Type

M12 Quick-disconnect, 4 conductor, DC keyed

Excitation Voltage

5.6 VDC or VAC (RMS) maximum

(Excess voltage can cause permanent damage)

Nominal Output Signal at Rated

MWF

+/- 100 mV per Transducer (with 5 VDC or VAC rms excitation

voltage)

Output Impedance

Approximately 64 Ohms per Bridge leg

Maximum Voltage, Gage to

Beam or Base (Ground)

50 Volts peak

Operating Temperature Range

0

o

F to +200

o

F

Maximum RPM

2500 (without derating)

Alignment

+/- 2 degrees angular displacement

Break-away torque

0.6 lb-in