Pacmate, FIg. 3 fig. 4, Technical data installation – intimus PacMate User Manual

Page 5: Malfunction / maintenance accessories, Disposing

PAPER JAM:

If too much materials is fed to the cutting system

the cutting system will jam. Proceed as follows:

- Operate the rocker switch (1) (fig. 1) to position

„bowed arrow“.

- The cutting system runs in reverse and free up

excess materials.

- Remove excess materials from the machine and

continue processing with a smaller amount of

material.

MOTOR PROTECTION:

The motor shuts down automatically, should it

become overloaded. Turn the machine off with

the rocker switch (1) (fig. 1) (position „0“). Allow

the motor to cool down for 15 to 20 minutes

(depending upon room temperature) and then

continue shredding.

CHECKLIST IN CASE OF MALFUNCTIONS:

If the device does not function, check the follo-

wing:

- is the

plug connected to the mains?

- is the

rocker switch (1) on?

- Is there a

material jam in the inlet chute?

Follow the instructions under „MATERIAL JAM

IN THE INLET CHUTE“.

- has the

motor been overloaded?

Wait until the motor has cooled, and then re-

start.

If none of the above applies, please contact

your dealer.

No structurel modifications may be

carried out!

In case of non-observance, the opera-

tion permission expires.

PacMate

TECHNICAL DATA

INSTALLATION

INSTALLATION INSTRUCTIONS:

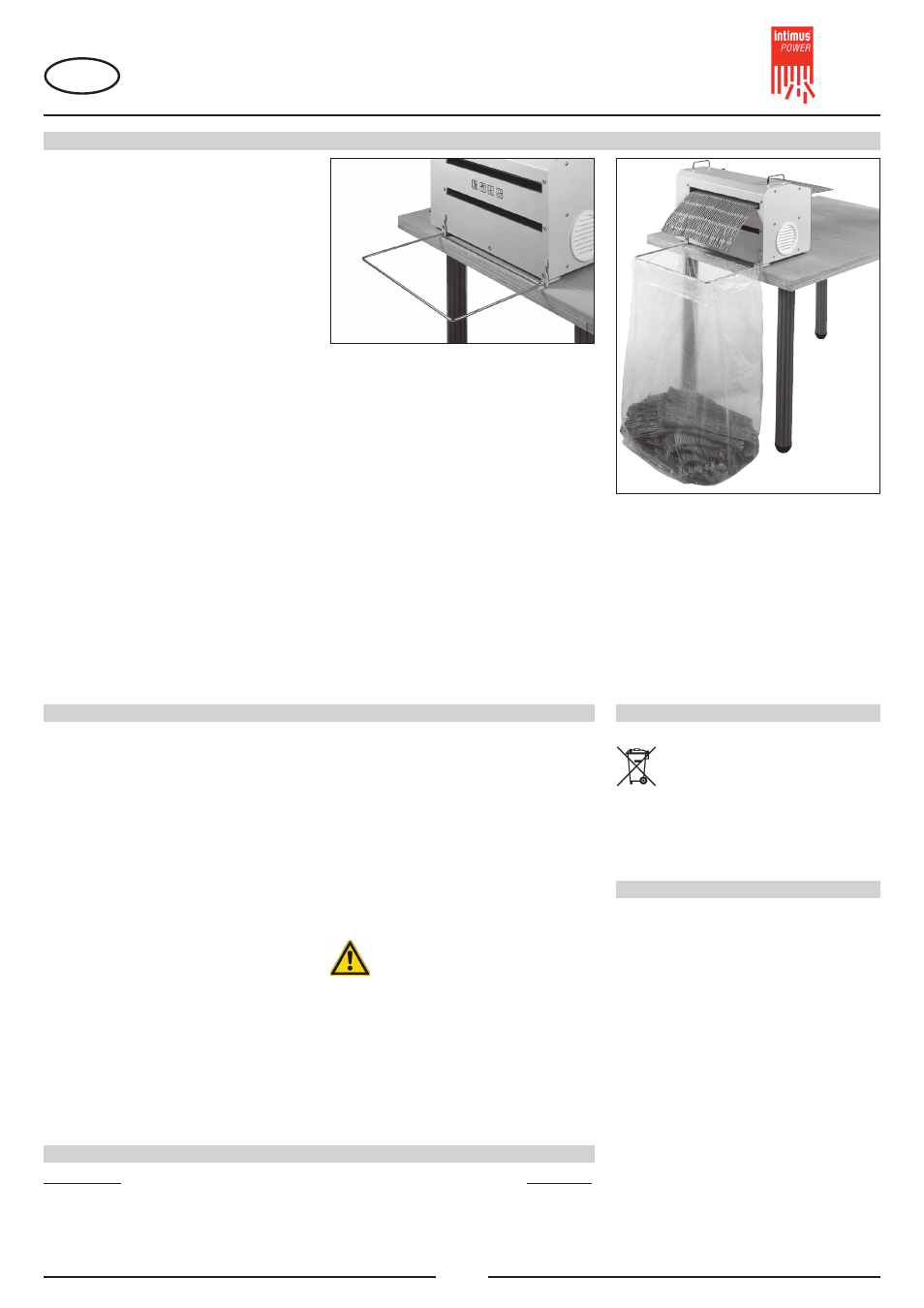

Proceed as follows when installing and setting

up the machine:

1. Place the machine on a table so that the two

feet at the back are lined up with the edge of

the table.

Do not worry: the machine‘s centre of gravity

is always located over the table and it cannot

tip over the edge.

2. Pull the metal frame for the waste bag out as

far as possible (fig. 3)

3. Hang the plastic bag into the frame and secure

it to the two hooks at the side of the housing.

Then fold the edge over the frame from the

inside out (fig. 4).

MALFUNCTION / MAINTENANCE

ACCESSORIES

Description

Order-No.

Plastic bag, 440 x 390 x 1100 x 0,03 mm

99951

Note: For orders of special accessories and spare parts, please contact your dealer.

Cutting width:

3.8x112 mm

Cutting capacity:

1 layer corrugated

board quality 1.2

(max. thickness of

cor. boards 18 mm)

Inlet guide:

10 mm

Working width:

400 mm

Cutting speed:

0.13 m/sec.

Power consumption:

1.1 kW

Intermittent service:

30 min – 15 min

Supply voltage:

230V/50Hz

240V/50Hz

120V/60Hz

100V/50/60Hz

Pre-fusing:

230V:

16 A

240V:

13 A

100V-120V:

20 A

Width:

525 mm

Depht:

300 mm

Height:

375 mm

Noise level:

approx. 61 dB(A)

Weight:

approx. 38 kg

GB

DISPOSING OF THE MACHINE:

Dispose of the machine in an

environmentally sound fashion at the end

of its useful service life. Do not dispose of

any of the parts included in the machine

or its packaging with household trash.

DISPOSING

5

fig. 3

fig. 4

Translation of the Original Operation Manual

Übersetzung der Originalbetriebsanleitung