Hach-Lange BUHLER 1027 2000 User Manual

Page 55

Operation

Page 55

Manual Bühler 1027

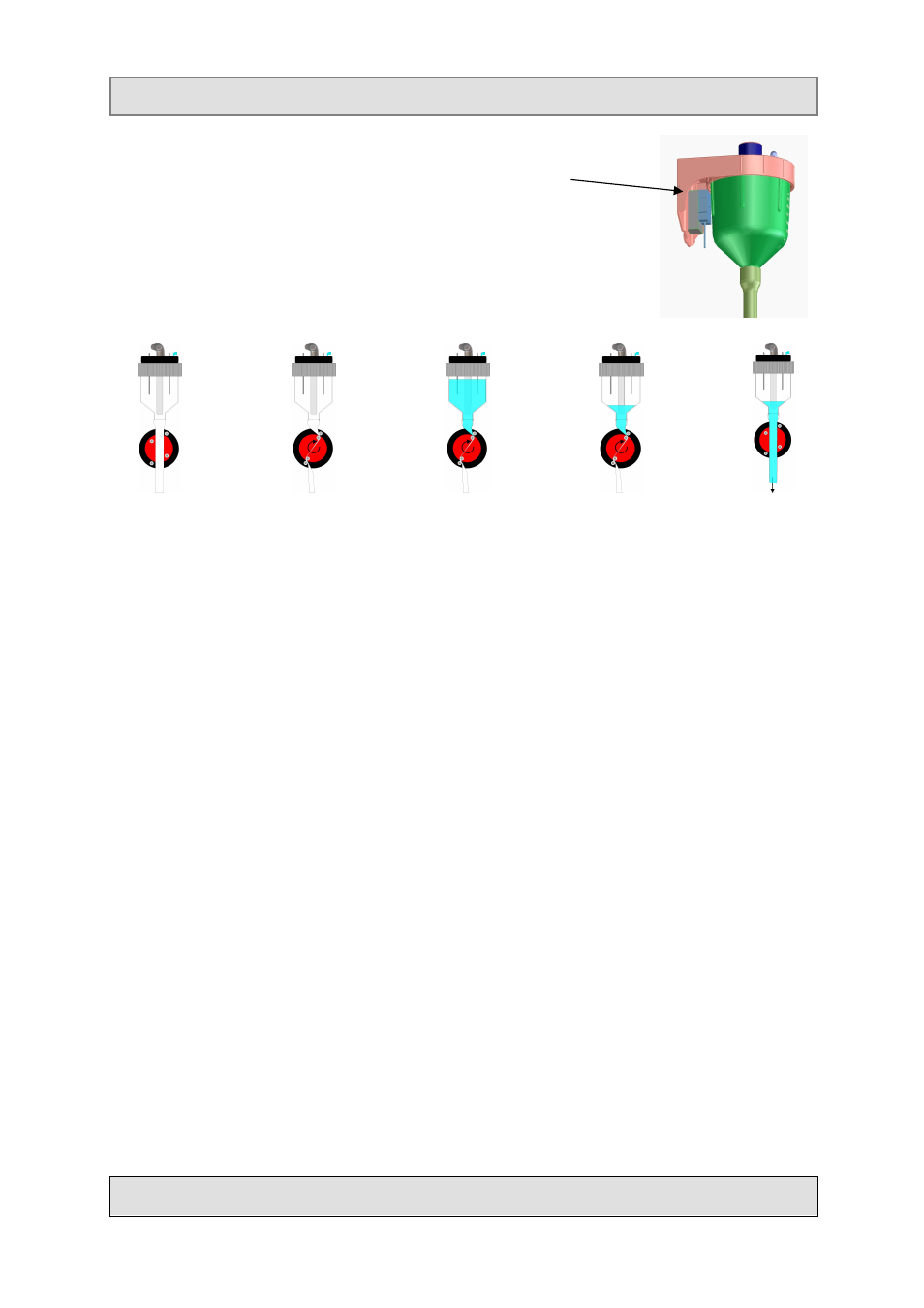

Option: Metering vessel with capacitive level sensor (non-contact)

Operation principle:

1. Inoperative

position

2. Pinch-valve

closes

3. Metering

vessel is filled

up to the

electrodes

4. Dosing system

is aerated

5. Pinch

valve

opens and

sample

drains off

in bottle

Replacement of the silicone discharge hose

The silicone hose (BM69301) is only pushed over the lip of the metering vessel. A hose clamp is not

required. Humidify the hose a little bit, fix it at one point and push it over the lip.

Remark:

Do only use original spare parts from the manufacturer. The use of a wrong hose type can lead to

malfunctions at the system or may even damage the pinch valve!

Remark:

Conductivity of the sample medium

There are two conductive level electrodes in the metering vessel. Their sensitivity can be adjusted in

the service menu. In the factory the electrodes are adjusted to tap water (this adjustment does not

have to

be changed under normal operating conditions). Minimum conductivity 50

μS/cm.

Please note that a wrong adjustment can lead to a flooding of the pneumatic system and to the

damage of component parts.

The sampler is not suitable for extraction of distilled water due to low conductivity.

Conductivity at 25°C

Rain water 50 μS/cm

Drinking water 500 μS/cm

Waste water 5000 μS/cm (5 mS/cm)

Seawater 50000 μS/cm (50 mS/cm)

ATTENTION:

Wrong operating conditions can lead to malfunctions or may even damage the apparatus. No liability

or claims under guarantee will be accepted in respect of any damage arising from the non-observance

of these operating instructions.