Cashco 964 User Manual

Page 2

IOM-964

2

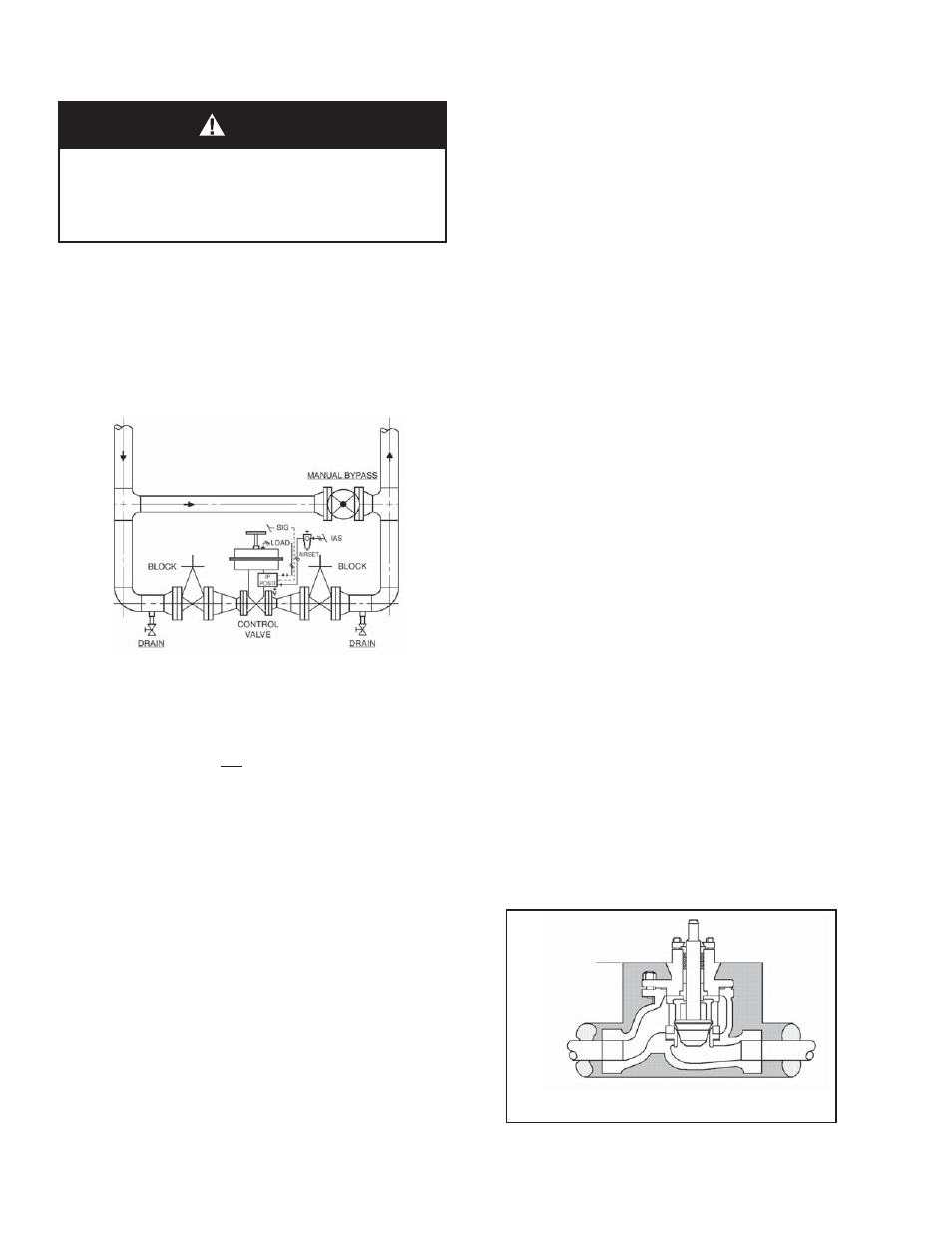

Figure 1: Typical Control Valve Station

Figure 2: Body Insulation

SECTION III

2. Outdoors, all in stal la tions may be ori ent ed any

angle from hor i zon tal-to-vertical.

3. Valves are not recommended for in stal la tion

with the actuator oriented down wards.

.

B. Piping System:

1. It is recommended that the control valve unit

be in stalled with a double-block and bypass

as in di cat ed in Figure 1. This ar range ment is

rec om mend ed es pe cial ly where main te nance

will be done on the valve body while still in-

stalled in the pipeline.

2. Pipe unions are recommended for NPT

screwed or socket welded installations to al low

complete removal from sys tem. If re mov al

for main te nance is by cutting torch for socket

welded valves, leave suffi cient pipe nipple

space be tween the 964 body and the next

piping com po nent up or down stream to allow

socket weld couplings for re-in stal la tion.

3. If pipe reducers are located before and/or after

the valve body, keep the reducers as close as

prac ti cal to the valve body; this is especially

important where the reducers are more than

one line size larger than the valve body size,

which is common in gaseous ser vice.

4. Clean the piping of all foreign debris, in clud ing

chips, weld scale, weld spatter, oil, grease,

sand or dirt prior to in stall ing the control valve.

This is an absolute re quire ment for valves

supplied with composition soft seats. System

start-up strain ers, for removal shortly after

initial start-up, are rec om mend ed.

5. Field hydrostatic testing the com plet ed piping

system to 1-1/2 x CWP in psig indicated on the

nameplate, including the 964, is ac cept able.

If hydro test pressure exceeds the 1-1/2 x

CWP limit, the 964 must be re moved for such

testing. Before pres sur iza tion, the valve plug

should be lifted from the seat if of ATO-FC

action. Tighten packing as re quired.

6. In placing thread sealant on pipe ends prior

to en gage ment, ensure that excess ma te ri al

is removed and not allowed to enter the valve

upon start-up.

7. Flow Direction: Install so the fl ow direction

match es the arrow marked on the valve body.

8. For best performance, install in well drained

hor i zon tal pipe, properly trapped if a steam

service ap pli ca tion.

9. Valves are not to be direct buried un der ground.

10. Insulation may be applied as in di cat ed in Fig-

ure 2. Drain age away from the packing area

must be ensured when fully in stalled, sealed

and lagged for outdoors in stal la tion.

III. INSTALLATION

A. Orientation:

1. Recommended

ori

en ta tion when in stalled in

a hor i zon tal pipeline with the stem ver ti cal.

Valves may also be in stalled in ver ti cal pipe-

lines with stems hor i zon tal.

CAUTION

For welded installations, all internal trim parts and

seals, must be removed from body prior to welding

into pipeline. The heat of fusion welding will dam age

non-metallic parts if not re moved. NOTE: This does

not apply to units equipped with extended pipe nip ples.

Limit of

Bonnet

Insulation