Cashco 764T Temperature Controller User Manual

Page 3

IOM-764T

3

Instrument air exposed to outdoor freezing tem-

per a tures must be desiccant dried. Re frig er at ed

drying is not ad e quate.

Instrument air exposed to indoors and/or no-freezing

tem per a tures is recommended to be re frig er ant

dried as a minimum.

If the air supply is at a remote location, and can

not be practically dried and bears oil (i.e. plant air),

co a lesc ing fi lters must be utilized to re move as

much oil and water as possible, as well as par ti cles

over 15 mi crons size.

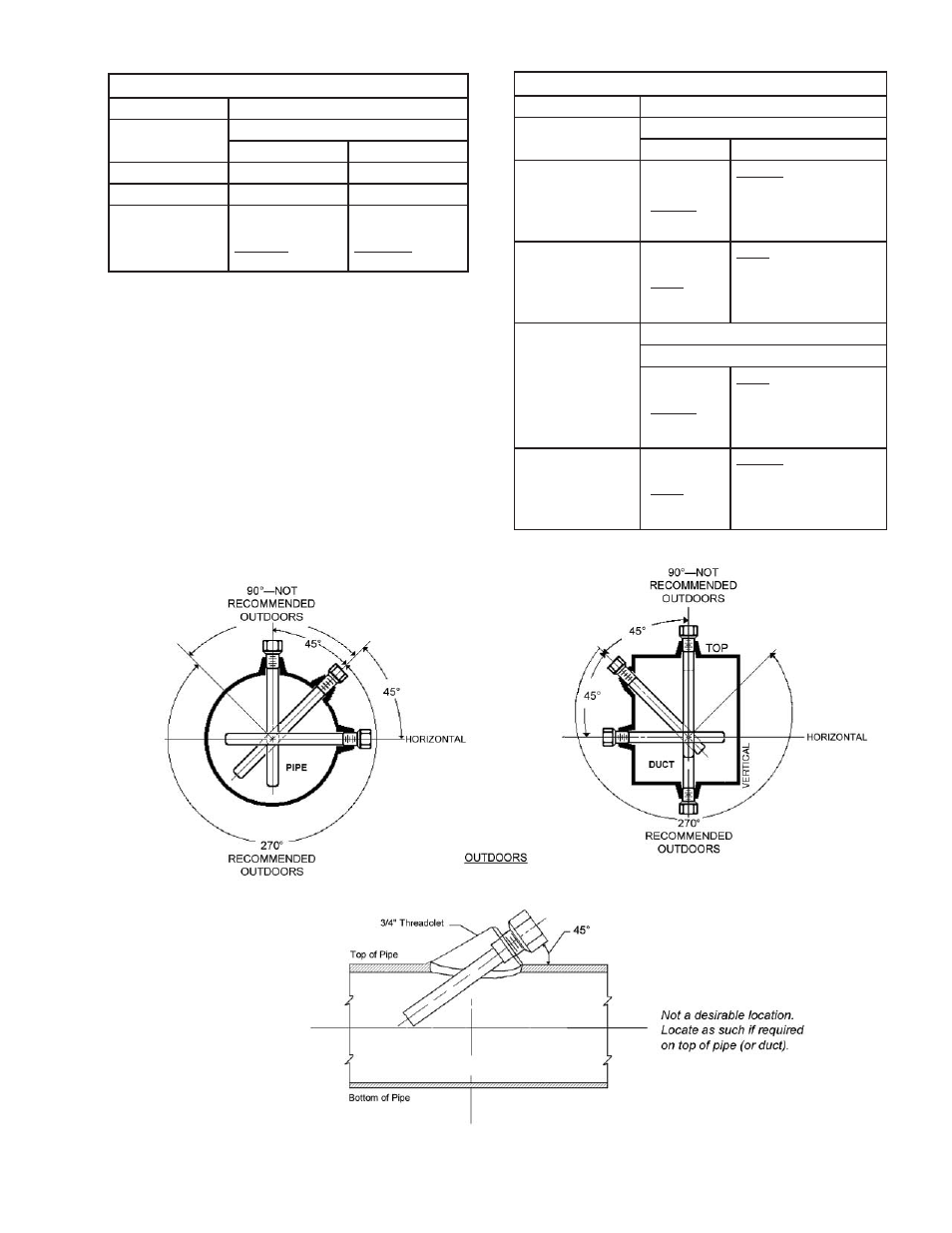

Figure 4: Recommended Thermal Well (Opt. 64) Installation

TABLE 1

Controller

Model 764T

ISA to

Port

Action

Direct

Reverse

A

Exhaust

Supply

B

Supply

Exhaust

PROCESS

TEMPERATURE

Increase in

temperature

increases output

signal

Increase in

temperature

decreases output

signal

TABLE 2

Controller

"Heating Applications"

IAS to

Port

Actions

Control Valve

Controller

A

ATO-FC

(Reverse)

Reverse

Increase in temperature

decreases output signal.

Valve "fails" to "cooler"

process temperature.

B

ATC-FO

(Direct)

Direct

Increase in temperature

increases output signal.

Valve "fails" to "hotter"

process temperature.

B

"Cooling" Applications

Actions

ATO-FC

(Reverse)

Direct

Decrease in temperature

decreases output signal.

Valve "fails" to "hotter"

process temperature.

A

ATC-FO

(Direct)

Reverse

Decrease in temperature

increases output signal.

Valve "fails" to "cooler"

process temperature.

11.

12.

13.