Hellwig Sway Bar 7868 User Manual

Page 4

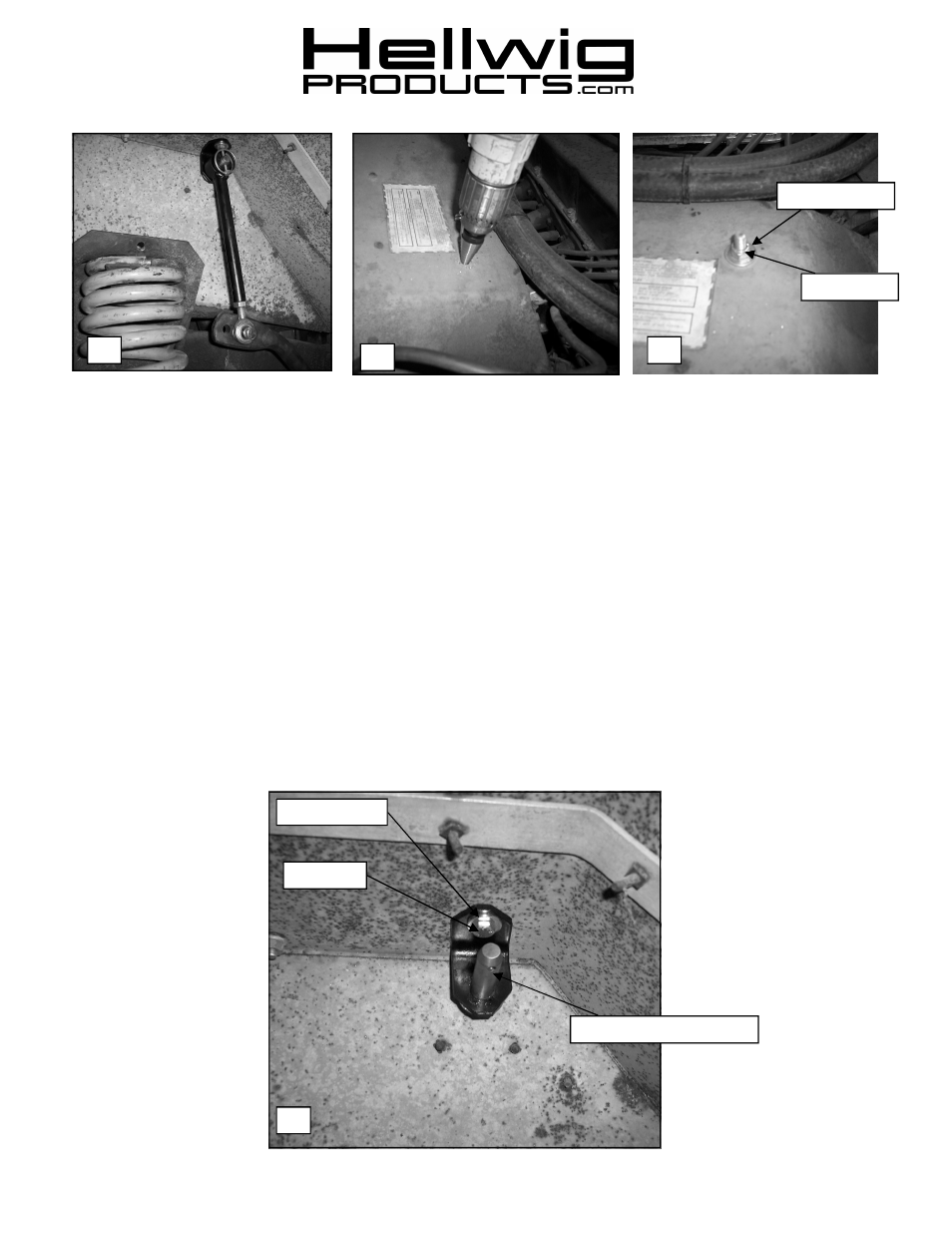

13

14

15

15. Disconnect the end link from the quick disconnect pin and rotate the bar and end link so the end link is against the inside wheel

well. See PHOTO 13.

16. Connect the end link quick disconnect pins to the end link fender tab in the same manner used for the end link lower mounting

bracket.

17. Align tab for best fit and mark where to drill the hole.

BEFORE DRILLING, DISCONNECT BATTERY AND VERIFY

THAT DRILL WILL NOT CONTACT OR DAMAGE ANY BRAKE, FUEL, COOLANT LINES,BATTERY, ELEC-

TRICAL COMPONENETS, WIRING, OR ANY OTHER ENGINE COMPARTMENT COMPONENTS.

18. Drill a 5/16” (.3125”) hole and bolt the end link fender tab to the inner fender. See PHOTOS 14, 15 & 16. The end links can be

disconnected from the axle and moved to these locations when the vehicle is being used offroad and needs additional suspen-

sion flex. For onroad use, leave the end link attached to the lower end link mounting bracket.

19. With the end link attached to the end link fender tab as well as the axle,

bounce the vehicle checking for clearance on all

under carriage components: fuel tank, shocks, differential, brake and fuel lines, etc. Test drive the vehicle and recheck all

clearances and the installation alignment. Adjust as needed. Re-check your installation after one week of driving and periodi-

cally on a regular basis.

20.

The sway bars arms have three mounting holes. Mounting the sway bar on the outer hole (rear-most) is the nominal

position. For a firmer setting, use the inner holes. We recommend starting with the outer mounting hole until you are

accustomed to the vehicles new handling characteristics. Select the mounting point that best fits your driving style.

ATTENTION INSTALLER:

BE SURE THAT THE CUSTOMER RECEIVES THIS INSTRUCTION

SHEET, ALL IMORTANT NOTE CARDS AND THE WARRANTY FORM

559-734-7451 800-367-5480 FAX 559-734-7460

7868 (R-7868)

07/13/2011

16

3/8” Bolt

Quick Disconnect Pin

Stover Nut

Flat Washer

Flat Washer