Timing-advance test procedure, Volts & dwell measurements – GxT V086-01, Ferret 86, Tach-Adv-Dwell-Volts Timing Light User Manual

Page 2

TIMING-ADVANCE TEST PROCEDURE

This light measures advance by delaying the fl ash so that it

appears to align the crank shaft TDC mark to its pointer, and

then displaying the degrees delayed. Note that on engines

with ignition contact points, dwell affects timing and must be in

calibration before timing is adjusted.

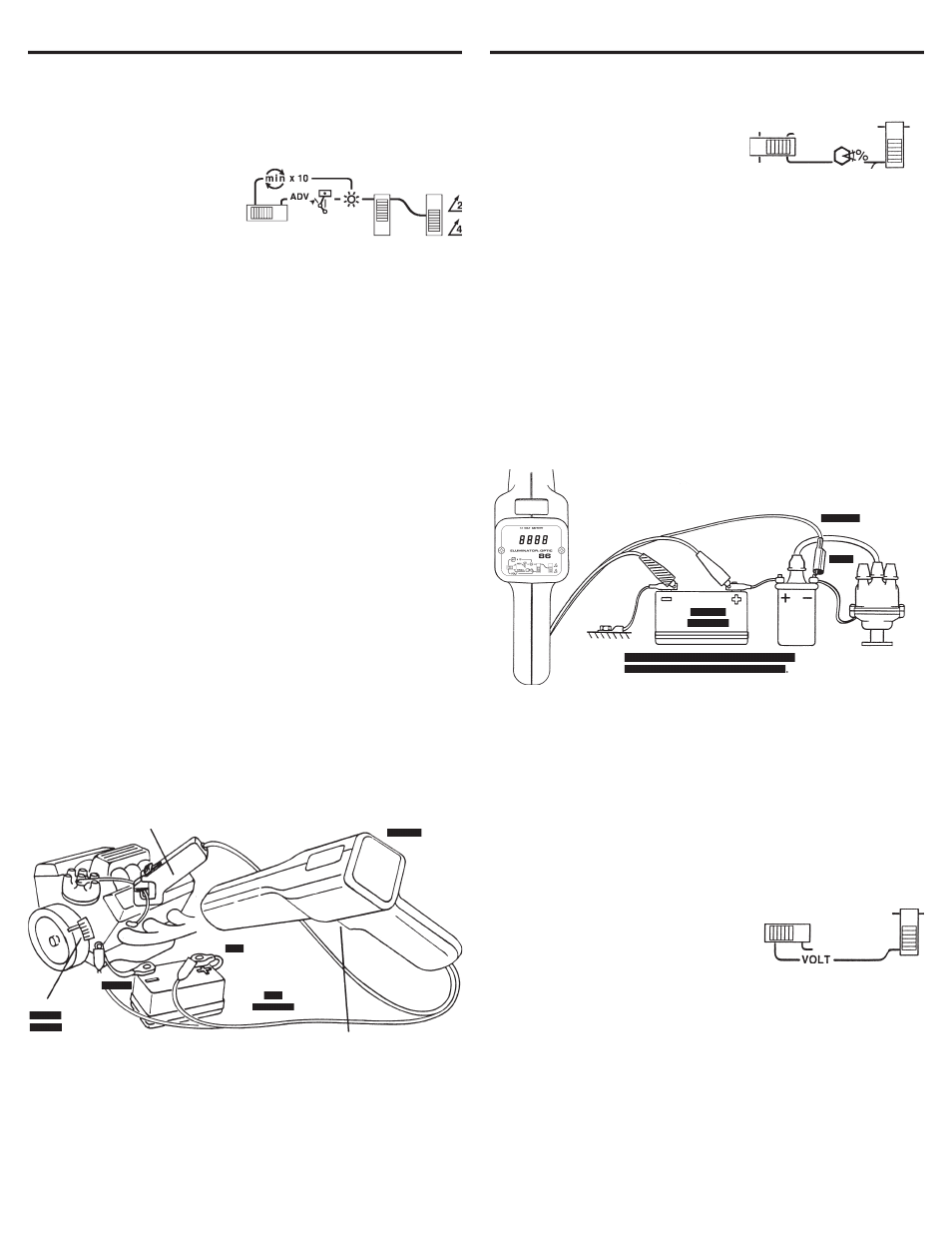

1. Connect the power

leads: RED - positive,

BLACK - negative. Push

the middle switch up for

strobe. Select the RPM x 10 display. Set the 2/4 stroke switch.

Place the Inductive Pickup around the #1 spark plug wire.

2. Prepare the engine for timing tests, such as: warming-up,

disabling electric and vacuum control lines, and cleaning the

wheel timing marks. Then run the engine. The light should

begin fl ashing.

3. Read RPM x 10, and set the engine speed to the test

specifi cation. Then slide the display switch toward the crank

angle symbol to read degrees of advance. The display will

show a decimal point one place from the right.

4. Point the light beam onto the degree marks at the engine

damper wheel or fl ywheel, and move the apparent mark to

the TDC position using the Timing Advance Control Buttons.

Then read the timing advance on the display.

5. Compare the measurement with the specifi cation. Timing

adjustments are made by turning the distributor slightly or

by moving the ignition timing sensor.

6. Restore all engine parts to their normal arrangement.

NOTE: Align your eye squarely with the timing marks when

viewing, to avoid parallax error. The strobe light may be aimed

from the side, but marks must be

INDUCTIVE PICKUP AROUND

SPARK WIRE

TIMING ADVANCE

CONTROL BUTTONS

YELLOW CLIP IS

NOT USED FOR

TACH OR

TIMING.

VOLTS & DWELL MEASUREMENTS

Connect Power Leads to the engineʼs 12 volt battery. Have

the middle switch pushed down. Use the YELLOW clip lead to

sense dwell and voltage on ignition coils, control solenoids, and

sensors. This clip does not affect

RPM or Advance readings.

IGNITION DWELL

This reading gives the percent of time that a coil minus terminal

is switched to ground. To use, push the left switch toward the

right, by the cam angle symbol. The display will show a decimal

point one place from the right. With the test clip disconnected

or grounded, the display will read 100.0 ±1. It will read 0.00 if

connected to battery voltage. Connect the YELLOW clip to the

coil minus (TACH) terminal. Then run the engine.

If dwell specifi cation is only provided in degrees, use the following

formula:

DEGREES X CYLINDERS / 3.6 = DWELL PERCENT

For example:

54 deg.X 4 cyln/ 3.6 =60 %

36 deg.X 6 cyln/ 3.6 =60 %

27 deg.X 8 cyln/ 3.6 =60 %

DUTY CYCLE DWELL

Have the left switch toward the cam angle symbol on the right

side. Connect YELLOW clip to the signal terminal and run engine.

The dwell reading is the percent of time that the signal is switched

below this meterʼs 3 volt input threshold.

Most of these applications read the percent of time that fuel

metering solenoids are turned on. This includes Bosch K &

KE-Lambda Jetronic and GM mixture control carburetors. Most

systems are designed to operate around 50% duty. Follow testing

procedures specifi ed for each engine.

VOLTAGE MEASUREMENT

Push the left switch toward the left

side. A decimal point will be on the

display two places from the right.

Touch the YELLOW clip to a voltage

test terminal. The display shows the DC voltage from the

YELLOW clip to the battery minus clip. The usable range is from

0.00 through 19 volts DC.

Input impedance is 175 kilohms, so it is generally suitable for

circuits under 5 kilohm source impedance. This includes virtually

all signals within an automotive harness, with the exception of

O2 sensors. O2 lambda sensors usually have a high source

impedance (unless good and hot), so connection to them may