BJM Pumps PGV220-575T User Manual

Page 16

16

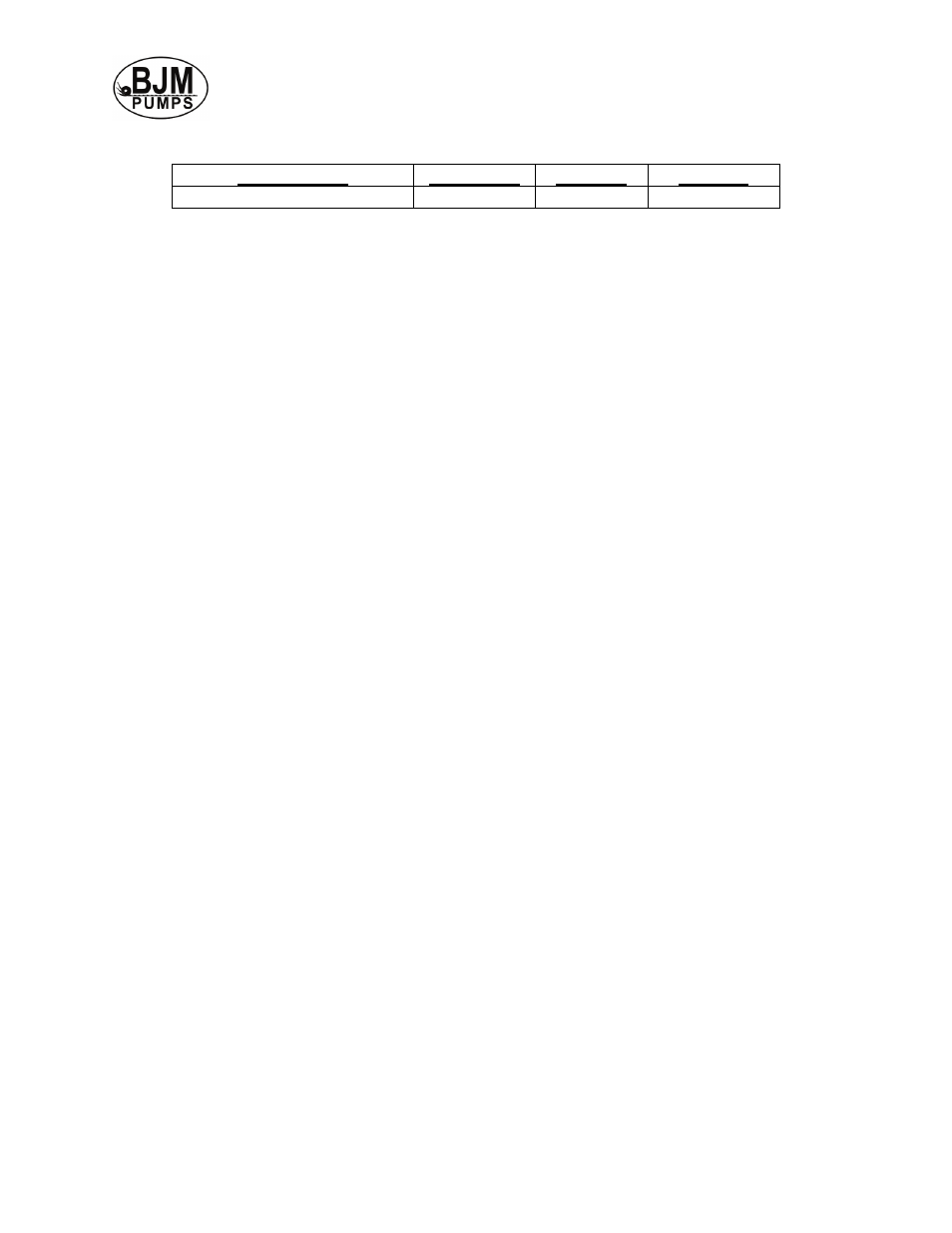

3. Required oil volume: As Table-2

Pump Model

PGV55, 75

PGV110

PGV220

Required oil volume (L)

1.3

1.6

5.8

Table 2 – Required Oil Volume in submersible pumps

4. Motor chamber check-When much water leakage is detected upon oil chamber

check, inspect further the motor chamber.

•

Should any leakage into the motor chamber be detected, the shaft seal

must be checked for abnormal wear and other fault. In this case, the pump

shall be overhauled. Follow Section 8 for the detailed overhauling

procedure.

•

If its measured insulation resistance is 20MΩ and over after adequately

dried, the stator is available for further continued use.

Periodic Inspection:

Periodically inspect the mechanical seal (most important check item), impeller,

bottom plate, dust seal, strainer, etc. to check that they are abnormal-free.

In addition, inspect the insulation resistance.

1) Oil chamber and shaft seal (mechanical seal) in case of continuous running; inspect

them at least once every 6 months.

2) Insulation resistance- check once per year. The pump motor may be further used

provided that the measured value is 1MΩ and over.

3) Impeller- in addition to periodic inspection, carefully inspect it when the suction

(pumping) capacity decreases, too. Refer to section 6.

4) Other Inspection- check the bolts and nuts for loose, damaged and deformation.

5) Overhauling- overhaul the pump at least once a year, though depending on the

service conditions, to inspect each component/part and replace any abnormally-

abrased part or faulty part with new one and clean adequately other parts available

for further use in thinner or washing oil. In addition, refill fresh oil in the oil chamber.

•

Each seal packing may be possibly damaged by over-hauling work. It

is therefore recommendable to stock and provide the spare parts

recommended in Section-7.

6) Inspection of Pumping Capacity- various causes for the decreased pumping capacity

are as described in section 12 “troubleshooting”. The causes by the impeller, bottom

plate, etc. are described hereunder.

1. Impeller- check whether or not the water passage is

narrowed and the pump function is disturbed by solids

adhered to the central boss of the impeller and between

vanes.

2. Passage in bottom plate and casing- check whether or not

the passage is narrowed by solids adhered to the bottom

plate and the casing.

7) Recommended Spare Parts- it is recommendable to stock the following parts which

may require replacement within 1 to 2 years from startup of the initial running.