Maintenance and inspection – BJM Pumps PGV220-575T User Manual

Page 12

12

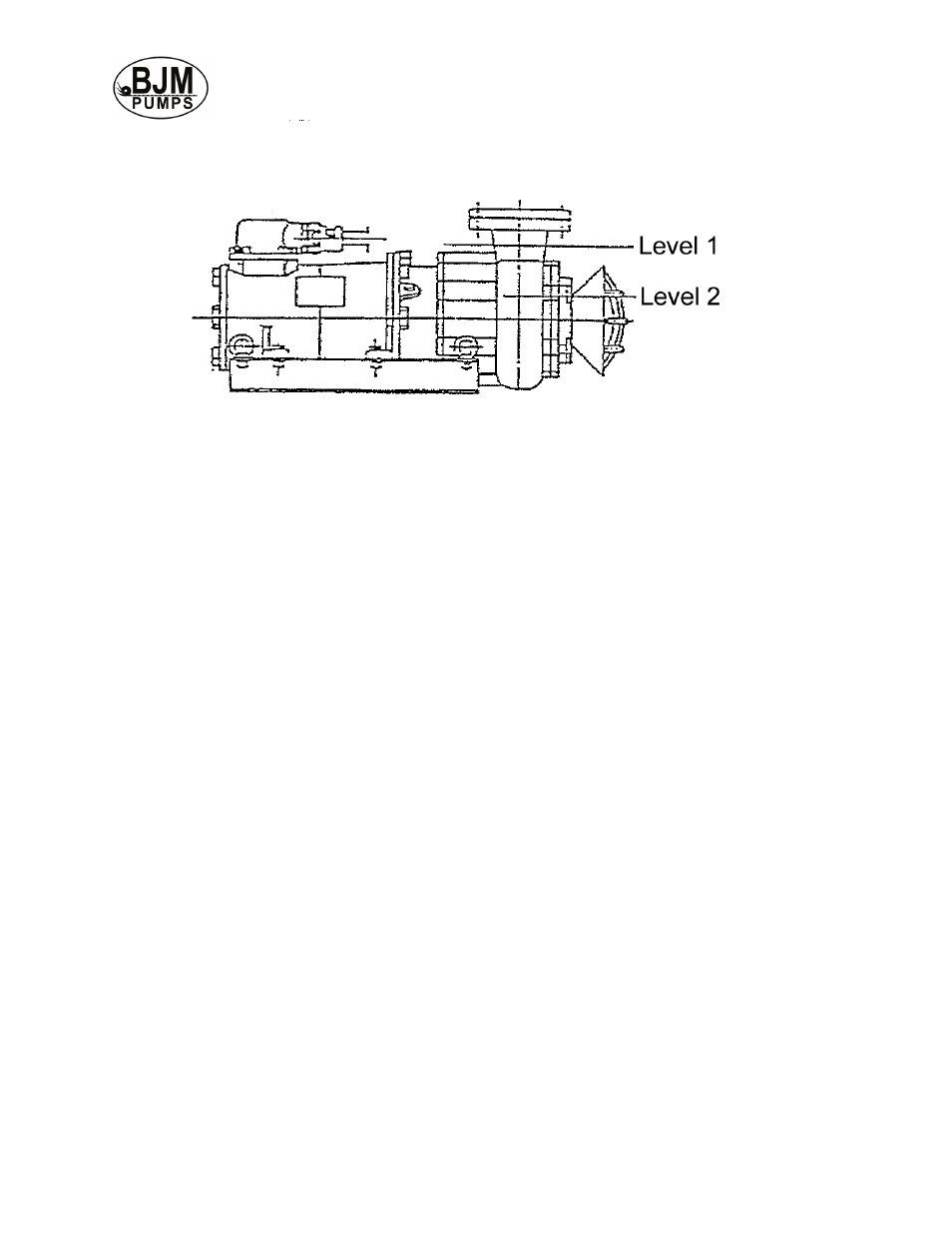

Figure 2

If the water level is below “LEVEL 2”, the suctioned air rate will increase; causing

pumping failure of the pump and finally the pump is put in no-load running condition.

In case of this pump, however, unlike vertical submersible pumps the motor frame of

this pump is submerged in the range from “LEVEL 1” to “LEVEL 2” so that the motor is

effectively cooled. When the water level is below “LEVEL 2”, the motor frame exposes

to the atmosphere and consequently the cooling effect comes down, but it is safety with

low temperature because of its non-load run condition.

2. Voltage check - during pump running; sometimes measure the power voltage to

check that it is within the range of 95% - 105% of the specified voltage.

3. Attention to pumping up of high density water where sand, slurry and other solids

are much contained in the pumping of water, the shaft power increases with

increasing mixture density of solids and the motor is eventually overloaded. (Special

technical instructions on this matter are available. It will be furnished upon request).

In such case, read the ammeter to monitor the electric current of the motor and adjust

the pump location.

MAINTENANCE AND INSPECTION

To service or repair your pump, please contact your local

BJM Pumps distributor.

Service should only be performed by a qualified electrician.

Insulation resistance of 1MΩ or greater, or unstable values with sudden drops indicates

potential malfunction and should be investigated.

Never touch terminals when measuring insulation resistance. Failure to observe this

caution may cause electric shock.

•

Pump should be disconnected from the electric power supply before proceeding

to do any service or maintenance

.