Application examples troubleshooting – Flowline LC1X Compact Controller User Manual

Page 6

Step Eight

Step Nine

APPLICATION EXAMPLES

TROUBLESHOOTING

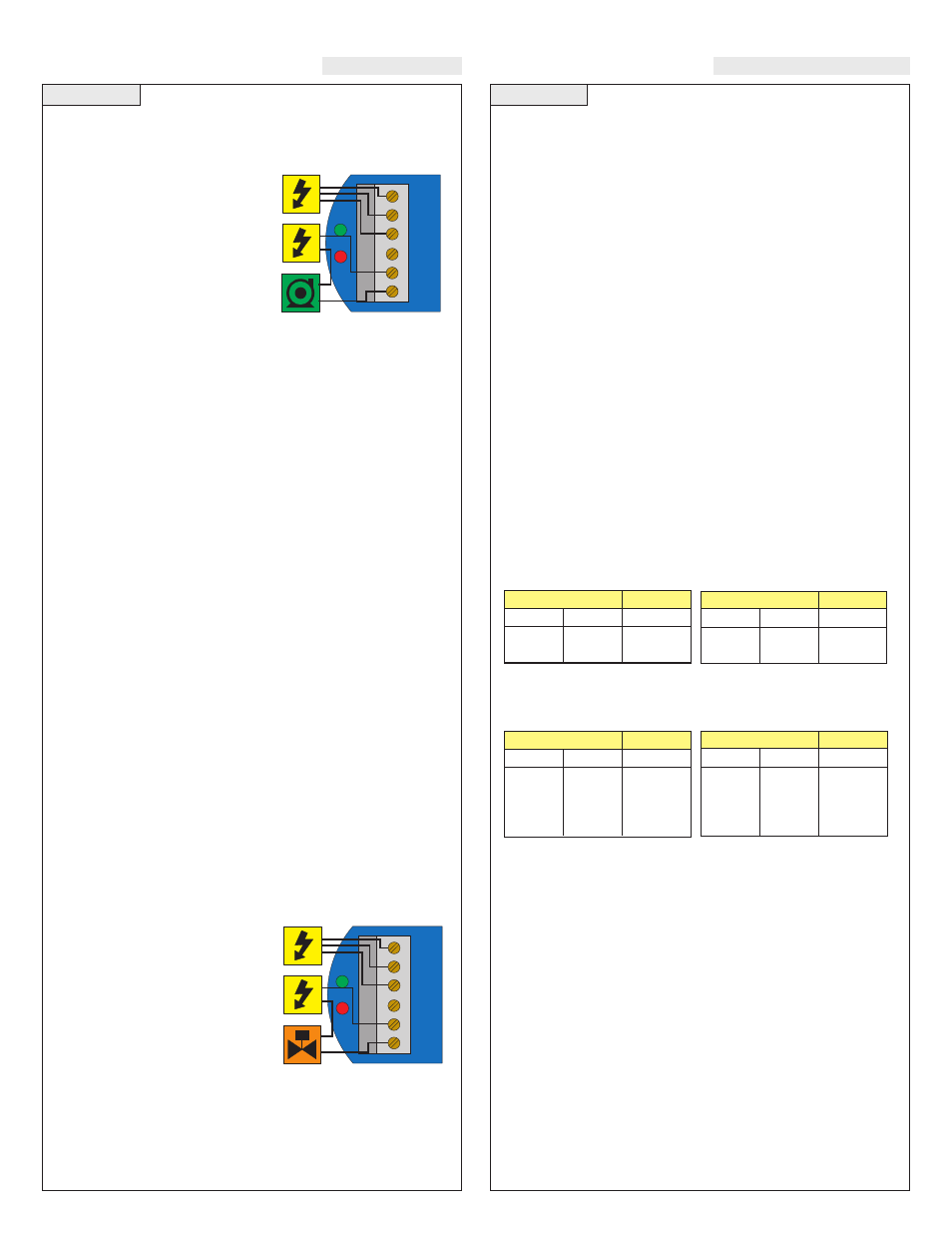

Automatic Fill:

This system consists of a tank with a high level sensor, a low level

sensor, and a pump that is controlled by the controller. Part of a prop-

er fail-safe design for this particular

system is that if power is lost to the

controller for any reason, the pump

filling the tank must be turned off.

Therefore, we connect the pump to

the NO side of the relay. When the

relay is energized, the pump will turn

on and fill the tank. The relay indica-

tor will correspond directly to the

On/Off status of the pump.

NOTE: If the pump motor load exceeds the rating of the controller’s

relay, a stepper relay of higher capacity must be used as part of the

system design.

Determining the settings of LATCH and INVERT

This is the way the system must operate:

•

When both the high and low sensors are dry, the pump should turn

on, starting to fill the tank.

•

When the low sensor gets wet, the pump should stay on.

•

When the high sensor gets wet, the pump should turn off.

Latch:

In any two-sensor control system, LATCH must be ON.

Invert:

Referring to the logic chart in Step Nine, we look for the set-

ting that will de-energize the relay (start the pump) when both inputs

are wet (Amber LEDs). In this system, Invert should be ON.

Determining A or B input connections:

When LATCH is ON,

there is no effective difference between Input A and B, since both sen-

sors must have the same signal in order for status to change. When

wiring any two-input relay section, the only consideration for hook-

ing a particular sensor to A or B is if LATCH will be OFF.

Automatic Empty:

Note that a similar system logic can be used for an automatic empty

operation simply by controlling a pump that pumps fluid out of the

tank instead of into it. However, note the importance of fail-safe

design. If the tank is being passively filled, and a pump must be used

to actively empty it, a power failure to either the controller or the

pump circuits will cause overflow.

Alternatively, an electrically-controlled drain valve could be used. In

this case, the valve should be a type that will automatically open if

power is lost; in other words, power must be used to hold it closed.

The valve would be connected to the NO side of the relay—if power

is lost to the controller, the relay de-energizes, the valve loses the

power that was holding it shut, and fluid will drain from the tank into

some other safe containment until

power is restored. In this system,

whenever the red relay LED of the

controller is ON, the drain is closed,

allowing fluid to rise.

In this case, Invert should be On:

when both sensors are wet, the relay

de-energizes, the switch to the valve

opens, and the tank will drain.

Controller Logic

For all controllers, please use the following guide to understand the

operation of the FLOWLINE LC11 controllers.

1. Power LED:

Make sure the Green power LED is On when

power is supplied to the controller.

2. Input LED(s):

The input LED(s) on the controller will be Amber

when the switch(es) is/are wet and Off when the switch(es) is/are

dry. Note: see Step 5 regarding reed switches. If the LED's are not

switching the input LED, test the level switch.

3. LC10 only:

When the input LED turn Off and On, the relay LED

will also switch. With invert Off, the relay LED will be On when

the input LED is On and Off when the input LED is Off. With

invert On, the relay LED will be Off when the input LED is On

and On when the input LED is Off.

4. LC11 only:

When both inputs are wet (Amber LED's On), the

relay will be energized (Red LED On). After that, if one switch

becomes dry, the relay will remain energized. Only when both

switches are dry (both amber LED's Off) will the controller de-

energize the relay. The relay will not energize again until both

switches are wet. See the Relay Latch Logic Chart below for fur-

ther explanation.

Relay Latch Logic Table (LC11 Only):

The relay can either be an independent relay (high or low level alarm)

or can be a latching relay (automatic fill or empty) with latch ON.

With Latch Off, the relay will only respond to the INPUT 1A setting.

INPUT 1B will be ignored.

With Latch ON, the relay will actuate when INPUT 1A and INPUT 1B

are in the same condition. The relay will not change its condition until

both inputs reverse their state.

Caution:

Some sensors (particularly buoyancy sensors) may have

their own inverting capability (wired NO or NC). This will change the

logic of the invert switch. Check your system design.

AC

AC

GND

NC

C

NO

R

P

AC

AC

GND

NC

C

NO

R

P

Input1A

ON

OFF

Input1B

No Effect

No Effect

Relay

ON

OFF

Invert OFF

Latch Off

Input1A

ON

OFF

ON

OFF

Input1B

ON

ON

OFF

OFF

Relay

ON

No Change

No Change

OFF

Invert OFF

Latch Off

Input1A

ON

OFF

Input1B

No Effect

No Effect

Relay

OFF

ON

Invert ON

Latch Off

Input1A

ON

OFF

ON

OFF

Input1B

ON

ON

OFF

OFF

Relay

OFF

No Change

No Change

ON

Invert OFF

Latch Off