Wiring, Maintenance, Vac power input wiring – Flowline AX1X Thermo-Flo User Manual

Page 6: Relay input wiring, Strobe alert output, General, Cleaning procedure, Testing the flow switch

Step Eight

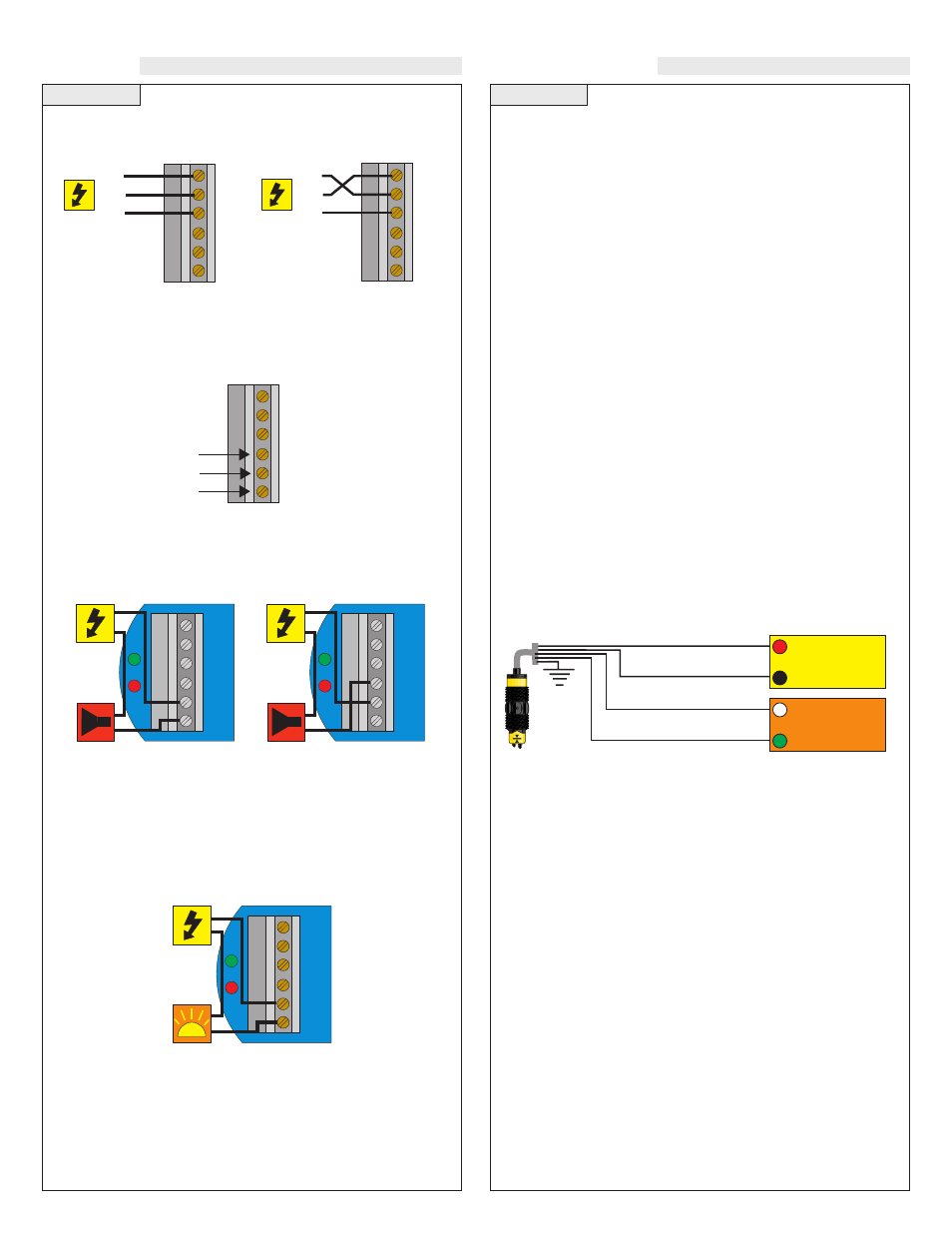

VAC Power Input Wiring:

Observe the labeling on the con-

troller. Note: Polarity does not matter with the AC input terminal.

Relay Input Wiring:

The relay is a single pole, double throw

type rated at 250 Volts AC, 10 Amps. The terminals Normally Open

(NO) and Normally Closed (NC) will be used in different applica-

tions. Remember that the "normal" state is when the relay coil is de-

energized and the Red relay LED is OFF (de-energized).

A typical application for the Switch Pro™ with Compact Relay

Controller is to operate a pump or valve between the two set points

(automatic fill or empty). In this application, a pump or valve can be

wired to either the Normally Open (NO) or Normally Closed (NC)

side of the relay.

AC

AC

GND

NC

C

NO

R

P

Strobe

HOT

NRTL

GND

AC

AC

GND

NC

C

NO

AC

AC

GND

NC

C

NO

HOT

NRTL

GND

AC

AC

GND

NC

C

NO

Relay

Terminals

Strobe Alert Output

With the Strobe Alert wired NO, the strobe will flash when the Red

LED is ON (Invert OFF). The strobe will flash when the Red LED is

OFF when wired NC or by turning the Invert ON. If the strobe is

wired NC and the Invert is ON, the strobe will flash when the Red

LED is ON (same as NO wiring and Invert OFF).

AC

AC

AC

AC

GND

GND

NC

NC

C

C

NO

NO

R

R

P

P

Alarm

AC

AC

AC

AC

GND

GND

NC

NC

C

C

NO

NO

R

R

P

P

Alarm

NO Wiring

NC Wiring

Power to

Switch Pro

not shown.

Power to

Switch Pro

not shown.

Power to

Switch Pro

not shown.

WIRING

Step Nine

MAINTENANCE

General:

The Switch-Pro™ flow switch requires no periodic

maintenance except to clean off any deposits or scaling from the sen-

sor tip as necessary. It is the responsibility of the user to determine

the appropriate maintenance schedule, based on the specific charac-

teristics of the application liquids.

Cleaning Procedure:

1. Power:

Make Sure that all power to the sensor, controller and/or

power supply is completely disconnected.

2. Sensor Removal:

Make sure that the flow is off and the pres-

sure is down prior to removing the Switch-Pro™. Carefully, remove

the sensor from the installation. Replace the sensor with a 3/4” NPT

plug to insure that liquid does not leak out during this procedure. Do

not re-install the Switch-Pro™ if the threads are damaged.

3. Cleaning the Sensor:

Use a soft bristle brush and mild deter-

gent, carefully wash the Switch-Pro™ flow switch. Do not use

harsh abrasives such as steel wool or sandpaper, which might

damage the surface sensor. Do not use incompatible solvents

which may damage the sensor's PP/Ryton or PVDF plastic body.

4. Sensor Installation:

Follow the appropriate steps of installa-

tion as outlined in the installation section of this manual.

Testing the Flow Switch:

Used to verify if the sensor is indicating a no-flow or flow condition.

This test uses all four-wires (Red, Black, White and Green). With Red

to Positive and Black to Negative, the Contacts (White and Green) will

be Open in a Flow Condition and Closed in a No-Flow Condition.

Also, the Red LED in the switch will ne OFF for a Flow Condition and

ON for a No-Flow Condition.

Red

Black

Shield

Ground

24 VDC

Power Supply

+

-

Multimeter

(Continuity)

-

+

White

Green