Components, Calibration, Component list – Flowline AX1X Thermo-Flo User Manual

Page 3: Standard configuration

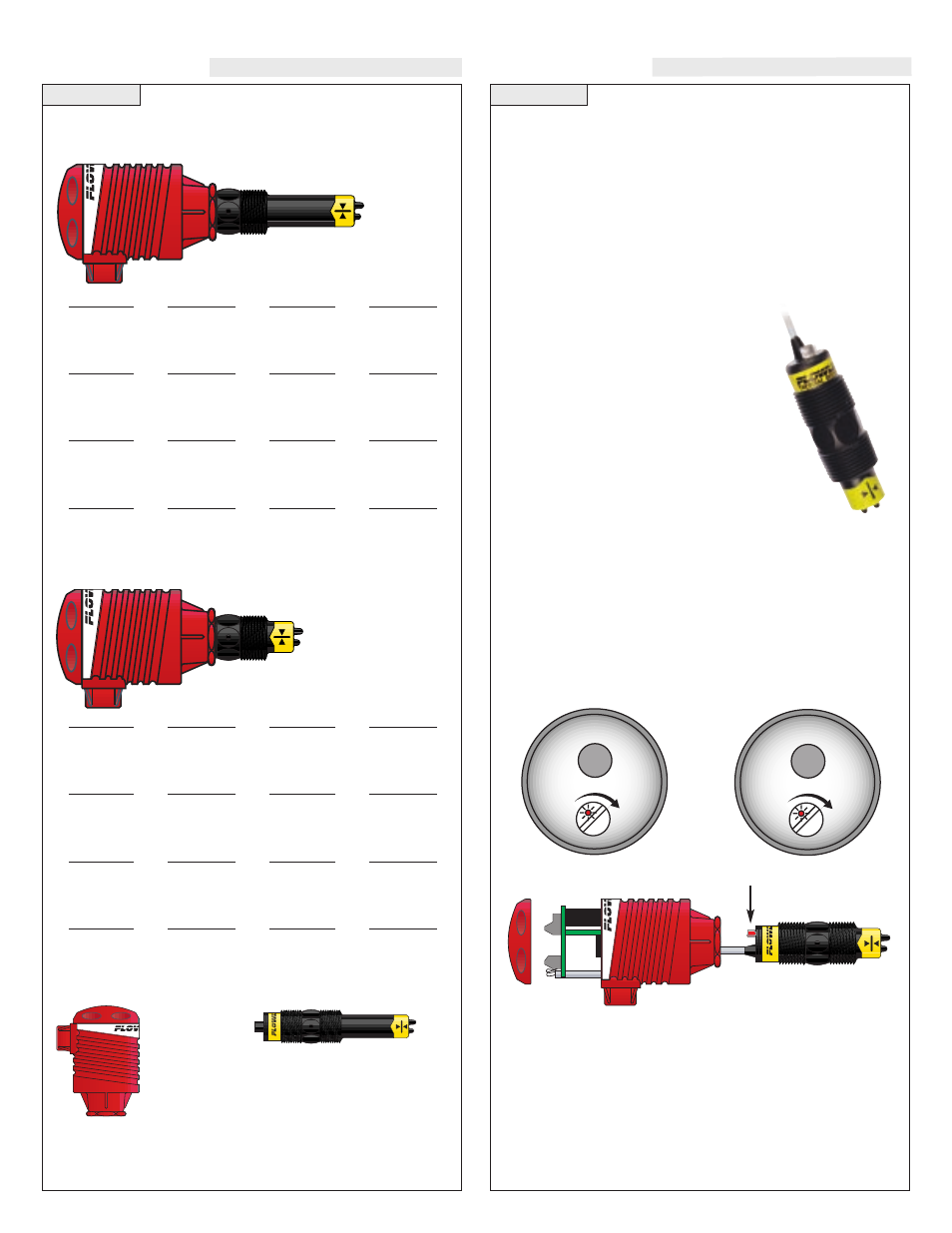

Step Two

COMPONENTS

AT14-1610

1 x FT10-1405

1 x LC10-1002

AT14-1614

1 x FT10-1425

1 x LC10-1052

AT14-3610

1 x FT10-5405

1 x LC10-1002

AT14-3614

1 x FT10-5425

1 x LC10-1052

AG14-1610

1 x GT10-1405

1 x LC10-1002

AG14-1614

1 x GT10-1425

1 x LC10-1052

AG14-3610

1 x GT10-5405

1 x LC10-1002

AG14-3614

1 x GT10-5425

1 x LC10-1052

AT14-1620

1 x FT10-1405

1 x LC10-1001

AT14-1624

1 x FT10-1425

1 x LC10-1051

AT14-3620

1 x FT10-5405

1 x LC10-1001

AT14-3624

1 x FT10-5425

1 x LC10-1051

AG14-1620

1 x GT10-1405

1 x LC10-1001

AG14-1624

1 x GT10-1425

1 x LC10-1051

AG14-3620

1 x GT10-5405

1 x LC10-1001

AG14-3624

1 x GT10-5425

1 x LC10-1051

Component List:

Compact Relay Controller

P/N: LC10-1001, LC10-1051,

LC10-1002 or LC10-1052

Switch-Tek Level Switch

P/N: FT10-1305, FT10-1325,

FT10-5305, FT10-5325,

FT10-1405, FT10-1425,

FT10-5405, FT10-5425

Standard Configuration:

AT14-_6__ and AG14-_6__

AT12-_6__ and AG12-_6__

AT12-1610

1 x FT10-1305

1 x LC10-1002

AT12-1614

1 x FT10-1325

1 x LC10-1052

AT12-3610

1 x FT10-5305

1 x LC10-1002

AT12-3614

1 x FT10-5325

1 x LC10-1052

AG12-1610

1 x GT10-1305

1 x LC10-1002

AG12-1614

1 x GT10-1325

1 x LC10-1052

AG12-3610

1 x GT10-5305

1 x LC10-1002

AG12-3614

1 x GT10-5325

1 x LC10-1052

AT12-1620

1 x FT10-1305

1 x LC10-1001

AT12-1624

1 x FT10-1325

1 x LC10-1051

AT12-3620

1 x FT10-5305

1 x LC10-1001

AT12-3624

1 x FT10-5325

1 x LC10-1051

AG12-1620

1 x GT10-1305

1 x LC10-1001

AG12-1624

1 x GT10-1325

1 x LC10-1051

AG12-3620

1 x GT10-5305

1 x LC10-1001

AG12-3624

1 x GT10-5325

1 x LC10-1051

Step Three

Set Points:

If the preset factory calibration is not adequate for

your application, follow the calibration steps listed below. Note: the

switch's internal LED will be on when the switch detects no-flow and

will off when the switch detects flow.

1. Install the fitting and flow switch as described in the Installation

section of this manual. Turn the flow switch and controller power

on and adjust the flow rate to the application setting. If the medi-

um to be sensed is likely to be subject to high temperature varia-

tions, the flow switch should be set at the highest normal temper-

ature likely to be encountered.

2. Locate the potentiometer knob at the top

of the flow switch. The red LED is visible

through the potentiometer. (If the LED is

on, slowly adjust the potentiometer coun-

terclockwise, with a small flat head

screwdriver until the LED turns off.) The

adjustment is a single turn 270° poten-

tiometer. The initial response time of the

flow switch after adjustment is 1 to 10

seconds. Adjust the potentiometer in slow

increments and wait for the response.

If the LED is off, slowly adjust the poten-

tiometer clockwise until the light turns on.

Then turn the potentiometer counterclockwise to bring the LED

off at a reliable setting. Remember, adjust the potentiometer in

slow increments and wait for the response.

3. Verify that the new calibration is correct by lowering the system

flow rate below the set point and check to see that the red LED

turns on. Then increase the flow rate above the set point and ver-

ify that the red LED turns off accordingly.

Liquid Switch

Gas Switch

AT1_-_63_ Series

AG1_-_63_ Series

1 fps

90 fps

10 fps

.04 fps

3 fps

0.2 fps

CALIBRATION

Adjustment Potentiometer

Accessing the Adjustment Potentiometer:

Remove the

two screws from the top of the printed circuit board (PCB) and gently

slide the PCB from the housing. Use caution when removing the PCB.

You will now be able to see the potentiometer through the housing. Make

any necessary adjustment. Note: Electrical wiring of any liquid level

control system should be performed in accordance with all applicable

national, state, and local codes. When completed, gently return PCB

into housing and replace the two screws.