Installation wiring, Wiring to a flowline controller – Flowline GT10 Thermo-Flo User Manual

Page 4

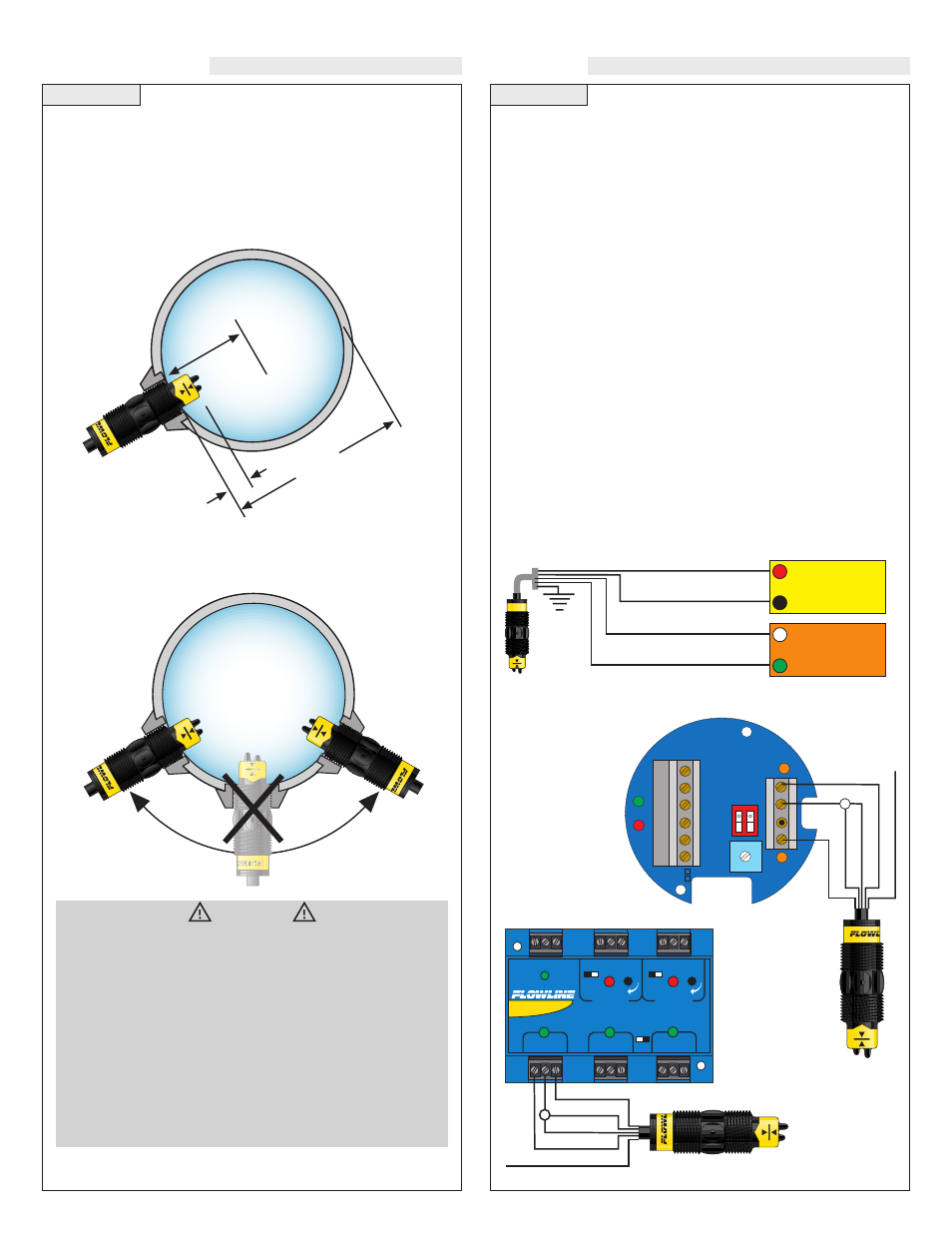

Step Four

Step Five

INSTALLATION

WIRING

When using any type of fitting, the orientation as well as the insertion

depth of the flow switch in the pipe is critical. See the diagram below

for the recommended orientation depth.

The FT10 series flow switch must always be in contact with

the liquid being measured. The GT10 series flow switch must

never be submersed in liquid. Both flow switches feature a

3/4" NPT threads which will allow it to be used with various

types of fittings. Be sure to check the insertion depth of the

flow switch in the fitting after it is installed. See the diagram

below for the recommended insertion depth.

WARNING

The flow switch tips have a thin plastic wall which may be dam-

aged if dropped or installed improperly.

The FT10 flow switch is designed for use in liquid. For best

results, avoid installing the FT10 where bubbles are present or

where the tips of the switch may be out of the liquid.

The GT10 flow switch is designed for use in gas applications.

For best results, avoid installing the GT10 where it may be sub-

mersed in liquid.

Note: Always install the Viton gasket with all versions of the

FT10-__2_. The G threaded version will not seal unless the gas-

ket is properly installed.

1/8 Pipe ID min.

Pipe ID

Acceptable

Insertion Range

Wiring to a Flowline Controller:

LC30 Series Controller

LC80 Series Controller

INVERINVER

T

+/- +/-

LALA

TCHTCH

DELA

DELAY

AC

AC

AC

AC

GND

GND

NC

NC

C

NO

NO

R

R

P

P

Input 1A

(S)

(S)

(-)

(-)

115 VAC

220 VAC

(+)

(+)

Green

Black

Shield - Not Used

White

Red

STANDARD

CONTROLLER

R E L A Y 1

R E L A Y 2

P O W E R

I N P U T 1

I N P U T 2 A

I N P U T 2 B

- +

- +

I N V E R T

D E L A Y

I N V E R T

D E L A Y

LATCH

ON OFF

Green

Red

White

Black

Not Used - Shield

Supply Voltage:

The supply voltage to the Thermo-Flo flow switch should never

exceed a maximum of 36 VDC. Use controllers or power supplies,

with a minimum output of 12 VDC or a maximum output of 36 VDC.

Required Cable Length:

Determine the length of cable required between the Thermo-Flo flow

switch and its point of termination. Allow enough slack to ensure the

easy installation, removal and/or maintenance of the sensor. The

cable length may be extended up to a maximum of 1000 feet, using a

well-insulated, 14 to 20 gauge shielded four conductor cable.

Wire Stripping:

Using a 10 gauge wire stripper, carefully remove the outer layer of

insulation from the last 1-1/4" of the sensor's cable. Unwrap and dis-

card the exposed foil shield from around the signal wires, leaving the

drain wire attached if desired. With a 20 gauge wire stripper, remove

the last 1/4" of the colored insulation from the signal wires.

Signal Output (Relay switching):

Allows the sensor to switch a small load on or off directly, using an

internal relay rated below 60 VA. The NO/NC status is set by the

polarity of the voltage feeding the red and black wires. The green

wire is the common for the relay and the white wire is the NO or NC,

depending on the polarity of red and black.

Normally Open Wiring:

Red

Black

Shield

Ground

24 VDC

Power Supply

+

-

Multimeter

(Continuity)

-

+

White

Green