Maintenance, Wiring – Flowline LH29 Switch-Tek User Manual

Page 8

Step Twelve

MAINTENANCE

General:

The Switch-Tek™ level switch requires no periodic maintenance

except cleaning as required. It is the responsibility of the user to

determine the appropriate maintenance schedule, based on the spe-

cific characteristics of the application liquids.

Cleaning Procedure:

1. Power: Make Sure that all power to the sensor, controller and/or

power supply is completely disconnected.

2. Sensor Removal: In all through-wall installations, make sure

that the tank is drained well below the sensor prior to removal.

Carefully, remove the sensor from the installation.

3. Cleaning the Sensor: Use a soft bristle brush and mild deter-

gent, carefully wash the Switch-Tek™ level switch. Do not use

harsh abrasives such as steel wool or sandpaper, which might

damage the surface sensor. Do not use incompatible solvents

which may damage the sensor's PP, PFA, PVDF or Ryton plastic

body.

4. Sensor Installation: Follow the appropriate steps of installa-

tion as outlined in the installation section of this manual.

Testing the installation:

1. Power: Turn on power to the controller and/or power supply.

2. Immersing the switch: Immerse the sensing tip in its applica-

tion liquid, by filling the tank up to the switches point of actua-

tion. An alternate method of immersing the switch during pre-

liminary testing is to hold a cup filled with application liquid up

to the switch's tip.

3. Test: With the switch being fluctuated between wet and dry

states, the switch indicator light in the controller should turn on

and off. If the controller doesn't have an input indicator, use a

voltmeter or ammeter to ensure that the switch produces the cor-

rect signal.

4. Point of actuation: Observe the point at which the rising or

falling fluid level causes the switch to change state, and adjust the

installation of the switch if necessary.

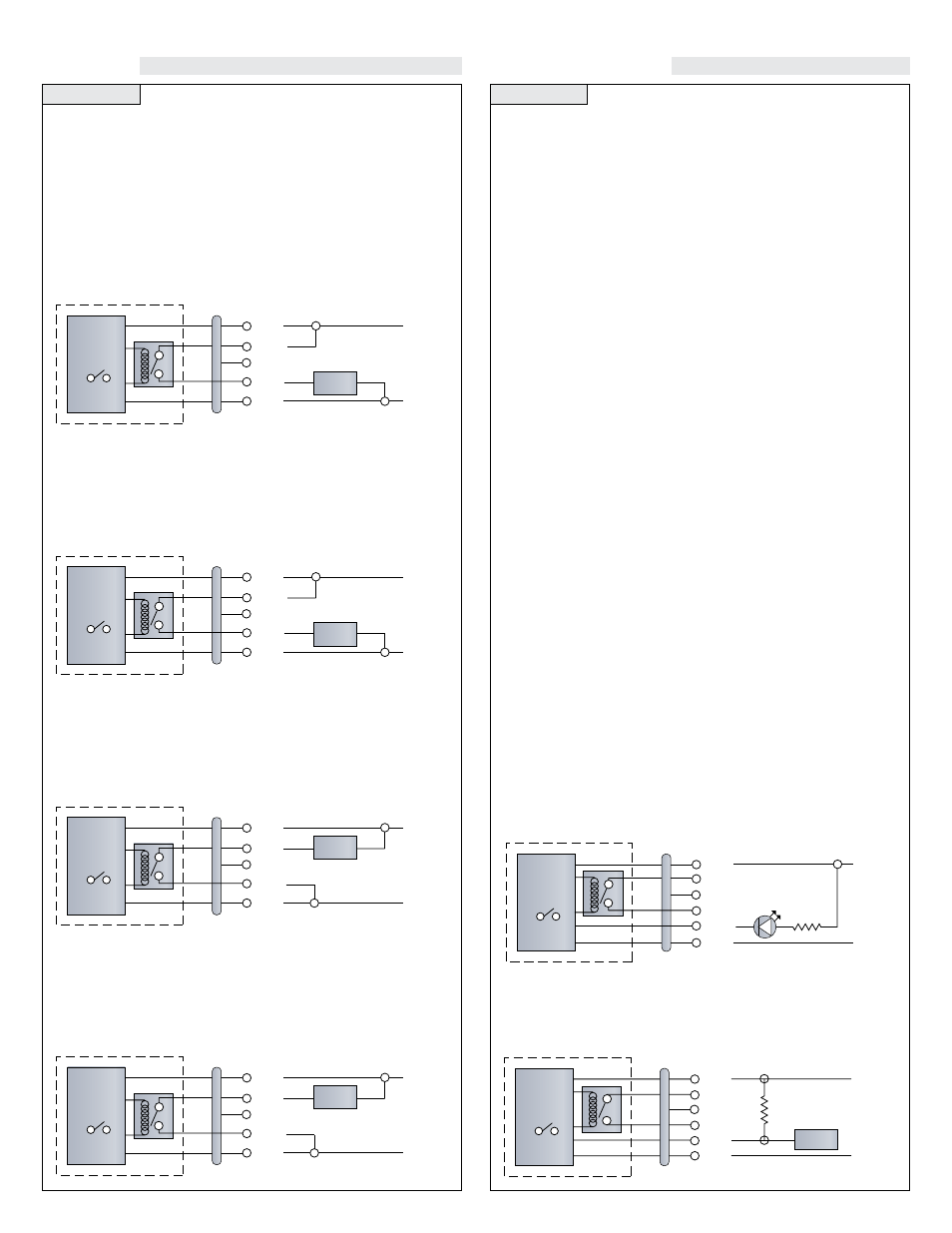

Maintenance Output to LED (LZ12 Only):

To wire the maintenance output wire to an LED, follow the wiring dia-

gram below. The Yellow wire is connected to the LED and a 2.2kΩ

resister in series and referenced back to the (+) of the power supply.

Step Eleven

WIRING

Wiring as a P-Channel or N-Channel output:

The Switch-Tek™ can be substituted for either a P-Channel (PNP,

sourcing) output or a N-Channel (NPN, sinking) output.

Normally Open DC Load as a P-Channel Output:

To wire as a NO P-Channel output, follow the directions below. The

Red wire connects to Positive (+) of the power supply and the Black

wire connects to Negative (-). The Green wire is jumpered to the Red

wire while the White wire is connected to the LOAD. Jumper the

LOAD back to the Negative (-) to complete the circuit.

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

BLK

LOAD

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

[Dry Condition]

Sensor

(NO)

BLK

GRN

SHLD

WHT

RED

LOAD

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

BLK

LOAD

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

[Dry Condition]

Sensor

(NO)

BLK

GRN

SHLD

WHT

RED

LOAD

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

Normally Closed DC Load as a N-Channel Output:

To wire as a NC N-Channel output, follow the directions below. The

Black wire connects to Positive (+) of the power supply and the Red

wire connects to Negative (-). The White wire is jumpered to the Red

wire while the White wire is connected to the LOAD. Jumper the

LOAD back to the Positive (+) to complete the circuit.

Normally Open DC Load as a N-Channel Output:

To wire as a NO N-Channel output, follow the directions below. The

Red wire connects to Positive (+) of the power supply and the Black

wire connects to Negative (-). The White wire is jumpered to the

Black wire while the Green wire is connected to the LOAD. Jumper

the LOAD back to the Positive (+) to complete the circuit.

Normally Closed DC Load as a P-Channel Output:

To wire as a NC P-Channel output, follow the directions below. The

Black wire connects to Positive (+) of the power supply and the Red

wire connects to Negative (-). The Green wire is jumpered to the

Black wire while the White wire is connected to the LOAD. Jumper

the LOAD back to the Negative (-) to complete the circuit.

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

YEL

BLK

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

MAINT. ALARM

[YEL Wire]

NPN Transistor

10 mA Max.

2.2K

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

YEL

BLK

PLC

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

MAINT. ALARM

[YEL Wire]

NPN Transistor

10 mA Max.

10K

24 VDC

Maintenance Output to PLC (LZ12 Only):

To wire the maintenance output wire to an PLC, follow the wiring dia-

gram below. The Yellow wire is connected to the PLC input with a 10

kΩ resister parallel to the PLC input and the (+) of the power supply.