Wiring, Assembly of smart trak – Flowline AX23 Smart Trak User Manual

Page 7

Step Nine

WIRING

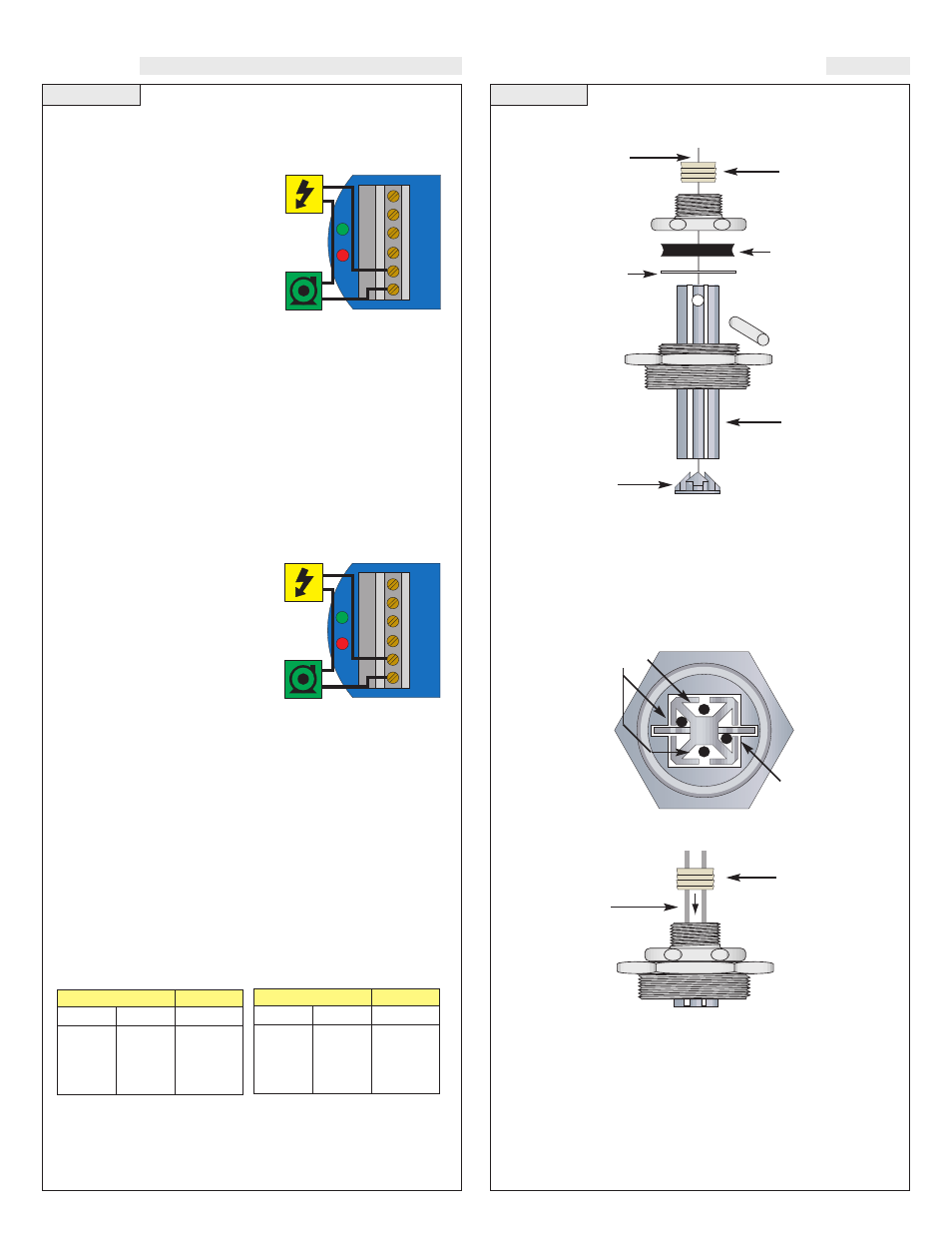

Smart Trak™ Assembly Drawing (Side View)

Inventory:

One Smart Trak™ kit (LM10-1__1) includes the following parts:

1 Seal Plug

1 Top compression fitting

1 Wire gasket

1 Thrust Plate

1 Locking pin

1 2" NPT fitting

1 Track

1 End cap

2 Wire retainer clips (not shown)

Smart Trak™ Assembly Drawing (Top View):

Seal Plug Assembly Drawing (Side View)

Seal Plug

Seal Plug

Sensor Wire

Wire Gasket

Thrust Plate

Locking Pin

2” NPT

Fitting

2” NPT

Fitting

Cable

Cable

must fit

into side of

track next

to locking pin

Track

End cap

Wires

Top Compression

Fitting

Top Compression

Fitting

Step Ten

ASSEMBLY OF SMART TRAK™

Automatic Fill:

This system consists of a tank with a high and

low level sensor, and a pump or valve that is operated by the con-

troller. Proper fail-safe design for this system is to stop filling if

power is lost. Therefore, we connect

the pump/valve to the NO side of the

relay. When energized, the device

will activate and fill the tank. The

relay LED will correspond directly to

the ON/OFF status of the

pump/valve. NOTE: If the pump

motor load exceeds the rating of

relay controller, a stepper relay of

higher capacity must be used as part of the system design.

Determining the settings of LATCH and INVERT

This is the way the system must operate:

•

When both the high and low sensors are dry, the device should

activate, starting to fill the tank.

•

When the low sensor gets wet, the device should stay ON.

•

When the high sensor gets wet, the device should turn OFF.

Latch:

In any two-sensor control system, LATCH must be ON.

Invert:

Referring to the logic chart in Step Nine, we look for the set-

ting that will de-energize the relay (start the pump) when both inputs

are wet (Amber LEDs). In this system, Invert should be ON.

Automatic Empty:

Note that a

similar system logic can be used for

an automatic empty operation simply

by controlling a pump/valve that

takes fluid out of the tank instead of

into it. Connect the pump/valve to

the NO side of the relay. When ener-

gized, the device will activate and

empty the tank.

Determining the settings of LATCH and INVERT

This is the way the system must operate:

•

When both the high and low sensors are wet, the device should

activate, starting to empty the tank.

•

When the high sensor gets dry, the device should stay ON.

•

When the low sensor gets dry, the device should turn OFF.

Latch:

In any two-sensor control system, LATCH must be ON.

Invert:

Referring to the logic chart in Step Nine, we look for the set-

ting that will de-energize the relay (start the pump) when both inputs

are wet (Amber LEDs). In this system, Invert should be OFF.

AC

AC

GND

NC

C

NO

R

P

Pump

AC

AC

GND

NC

C

NO

R

P

Pump

Relay Latch Logic Table:

With Latch ON, the relay will actu-

ate when INPUT 1A and INPUT 1B are in the same condition. The relay

will not change its condition until both inputs reverse their state.

Input1A

ON

OFF

ON

OFF

Input1B

ON

ON

OFF

OFF

Relay

ON

No Change

No Change

OFF

Invert OFF

Latch Off

Input1A

ON

OFF

ON

OFF

Input1B

ON

ON

OFF

OFF

Relay

OFF

No Change

No Change

ON

Invert OFF

Latch Off