Assembly of smart trak, Safety precautions – Flowline AX23 Smart Trak User Manual

Page 4

Step Four

ASSEMBLY OF SMART TRAK™

Step Three

SAFETY PRECAUTIONS

About this Manual:

PLEASE READ THE ENTIRE MANU-

AL PRIOR TO INSTALLING OR USING THIS PRODUCT. This

manual includes information on the Smart Trak™ with Compact

Relay Controller: AU23-43__, AZ23-43__ and AV23-34__. The

units are identical except for the number of switch points and the

sensors technology.

User's Responsibility for Safety:

Flowline manufactures

a wide range of liquid level sensors, controllers, and mounting sys-

tems. It is the user's responsibility to select components that are

appropriate for the application, install them properly, perform tests

of the installed system, and maintain all components. The failure to

do so could result in property damage or serious injury.

Proper Installation and Handling:

Use a proper sealant

with all installations. Never overtighten the components. Always

check for leaks prior to system start-up.

Material Compatibility:

Glass filled Polypropylene (PP, a polyolefin): Track, end cap, wire

retainer clips, bayonet adapter, level switch and sensor car for all

Smart Trak Assemblies.

Polychlorotrifluoroethylene (PCTFE, a fluoroplastic): Sensor car

locking bolt and screw.

Polypropylene (PP, a polyolefin): Sensor, top compression fitting,

thrust plate, locking pin and 2" NPT fitting.

Viton (a fluorocarbon): O-ring.

Neoprene (w/silicon gel for lubrication): Wire gasket.

Santoprene (w/silicon gel for lubrication): Seal plug.

Make sure that the application liquids are compatible with the

materials that will be wetted. To determine the chemical compati-

bility between the components and its application liquids, refer to

the Compass Corrosion Guide, available from Compass

Publications (phone 858-589-9636).

Temperature and Pressure:

Smart Trak™ is designed for

use in application temperatures up to 90° C (194° F). It is not

designed for pressurized applications due to the wiring that must

travel through a gasket at the head.

Wiring and Electrical:

Electrical wiring of any liquid level

control system should be performed in accordance with all applic-

able national, state, and local codes. Take care not to cut or break

the outer insulation jacket of wiring that may be immersed while

routing cables in the Smart Trak™ system. Such breaks of the liq-

uid seal of the sensor system may lead to component failure.

Flammable, Explosive and Hazardous Applications:

The AU23-43__, AZ23-43__ and AV23-34__ Smart Trak™ should

not be used within classified hazardous environments.

Make a Fail-Safe System:

Design a fail-safe system that

accommodates the possibility of system or power failure. In criti-

cal applications, Flowline recommends the use of redundant back-

up systems and alarms in addition to the primary system.

About Smart Trak™:

Flowline’s Smart Trak™ with Compact

Relay Controller Assembly is an adjustable mounting system for

installing two level sensors vertically within a tank. Mounted through

a single point at the top of the tank, both sensors can be adjusted in the

field. The compact relay controller features a 120/240 VAC latched

controller with a 250 VAC, 10A SPDT relay contract. Smart Trak™

mounts vertically through a standard 2" NPT tank adapter, or on a side

mount bracket (such as the LM50-1001). Unlike prefabricated “trees”

or pipes, Smart Trak™ allows you to experiment with sensor position

to account for variations in the point of actuation of each sensor dur-

ing process testing.

Track:

The track itself is approximately 1" square, and is from 8”

to 10' long depending on the A-Dimension. The track may be cut to

length if desired. Four separate grooves run the length of the track,

one on each side of the square. These grooves hold the sensor cars that

attach to Flowline sensors, and also serve to contain the switch cable.

The bottom of the track is capped with an end cap.

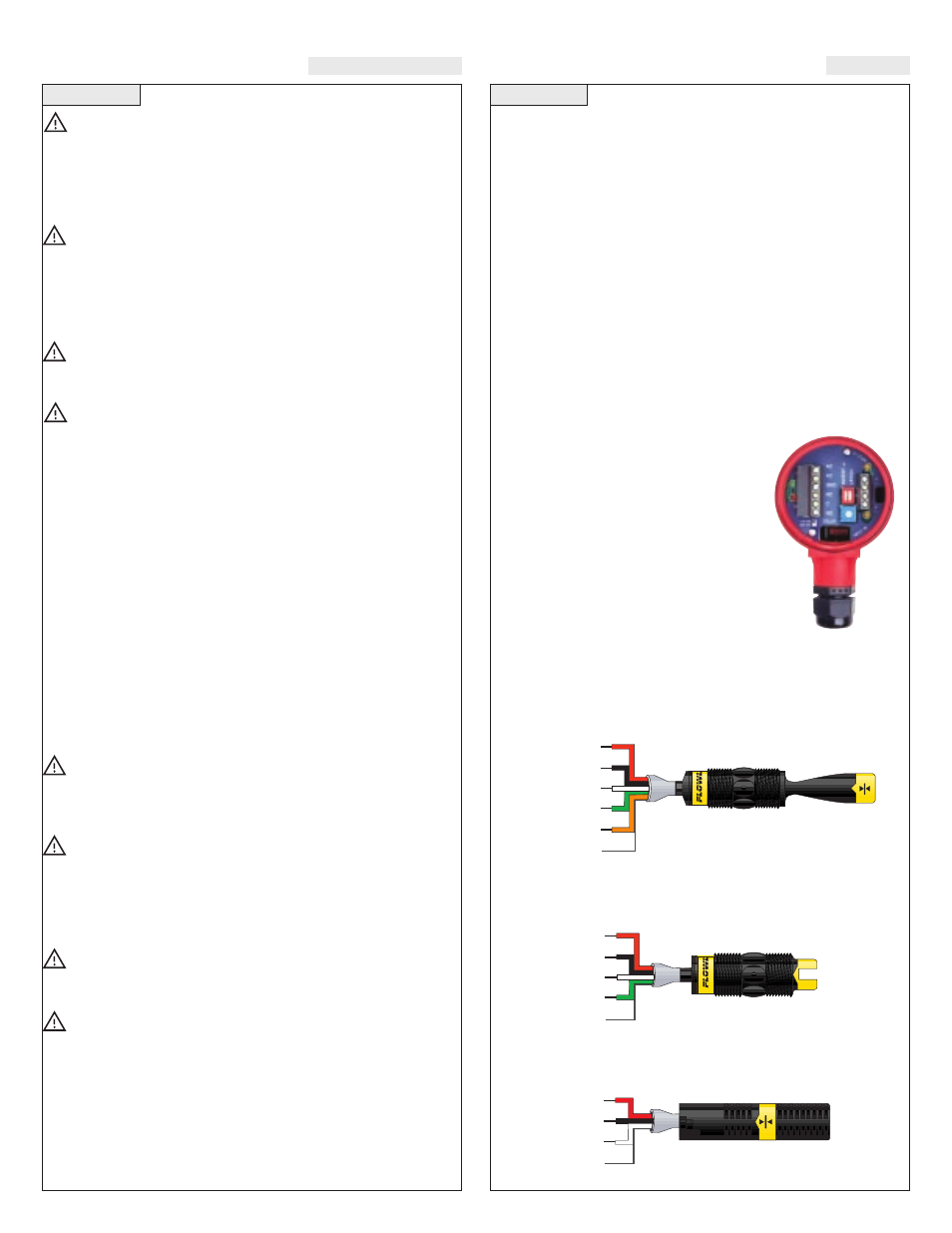

Relay Controller:

Both level switches

are pre-wired before shipment to the 4-pole

terminal strip [Input 1A (+) & (-) & Input 1B

(+) & (-)]. The switch technologies used to

indicate level are either Ultrasonic, Buoyancy

or Vibration. The Compact Relay Controller

provides a 1/2” Conduit connection and 6

poles for wire termination of power and relay

contact. Use the AC, AC and GND terminals

for providing power. Use the NC, NC and

COM terminals for interfacing to the relay

contact.

Vibration (LZ12-1405)

Wire Configuration:

RELAY

Red

Black

White

Green

Orange

(+)

(-)

N/A

N/A

N/A

Shld

RELAY

(+)

(-)

N/A

N/A

Shld

Red

Black

White

Green

REED

N/A

(-)

(+)

Shld

Red

Black

White

Ultrasonic (LU10-1305 or LU10-1325) Wire

Configuration:

Buoyancy (LV10-1301 or LV10-1351) Wire

Configuration:

Compact

Relay Controller

(inside shown)